Configuration

5.4 Installation

1FW6 Built-in torque motors

Configuration Manual, 07/2017, 6SN1197-0AE00-0BP9

127

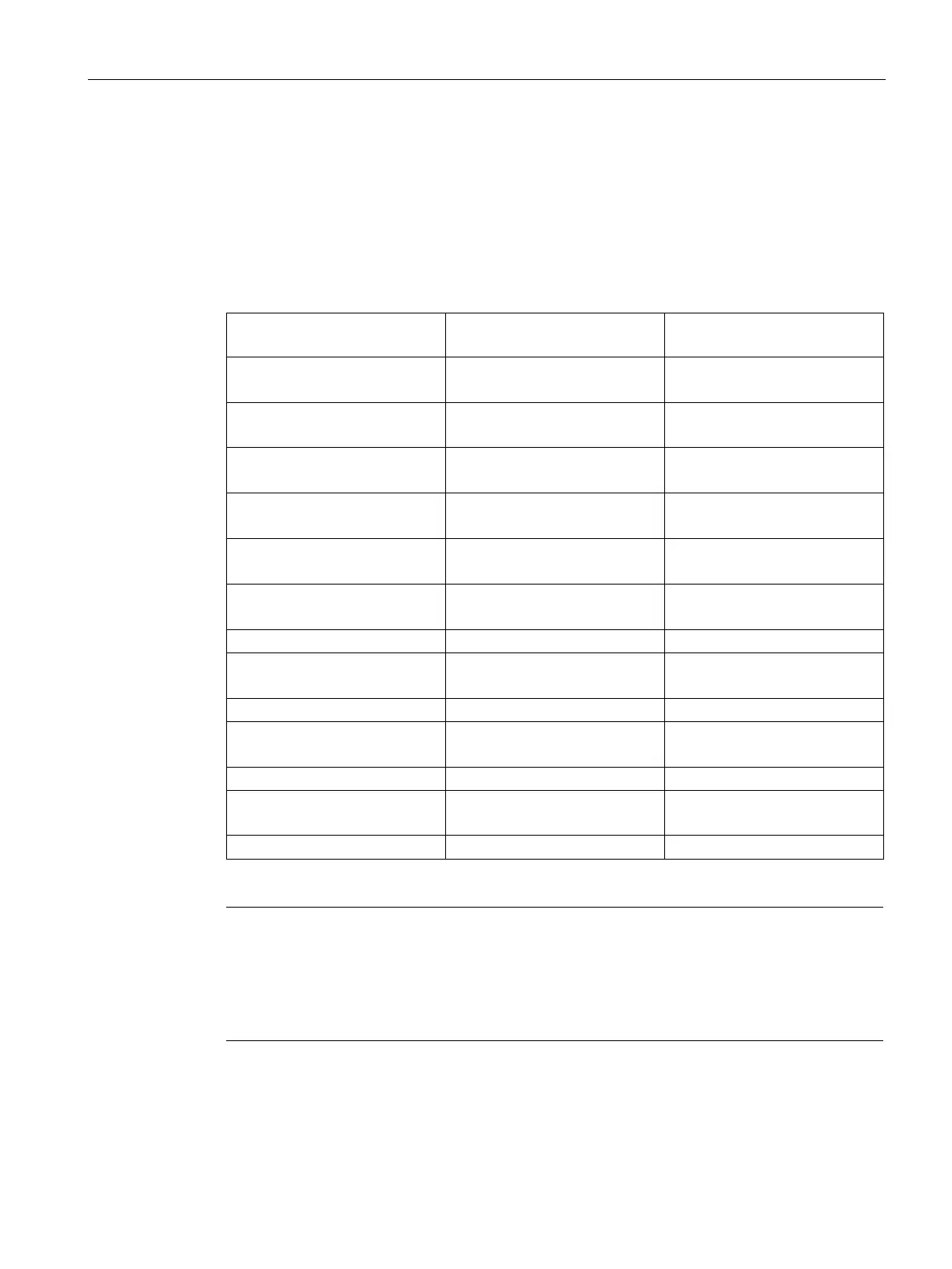

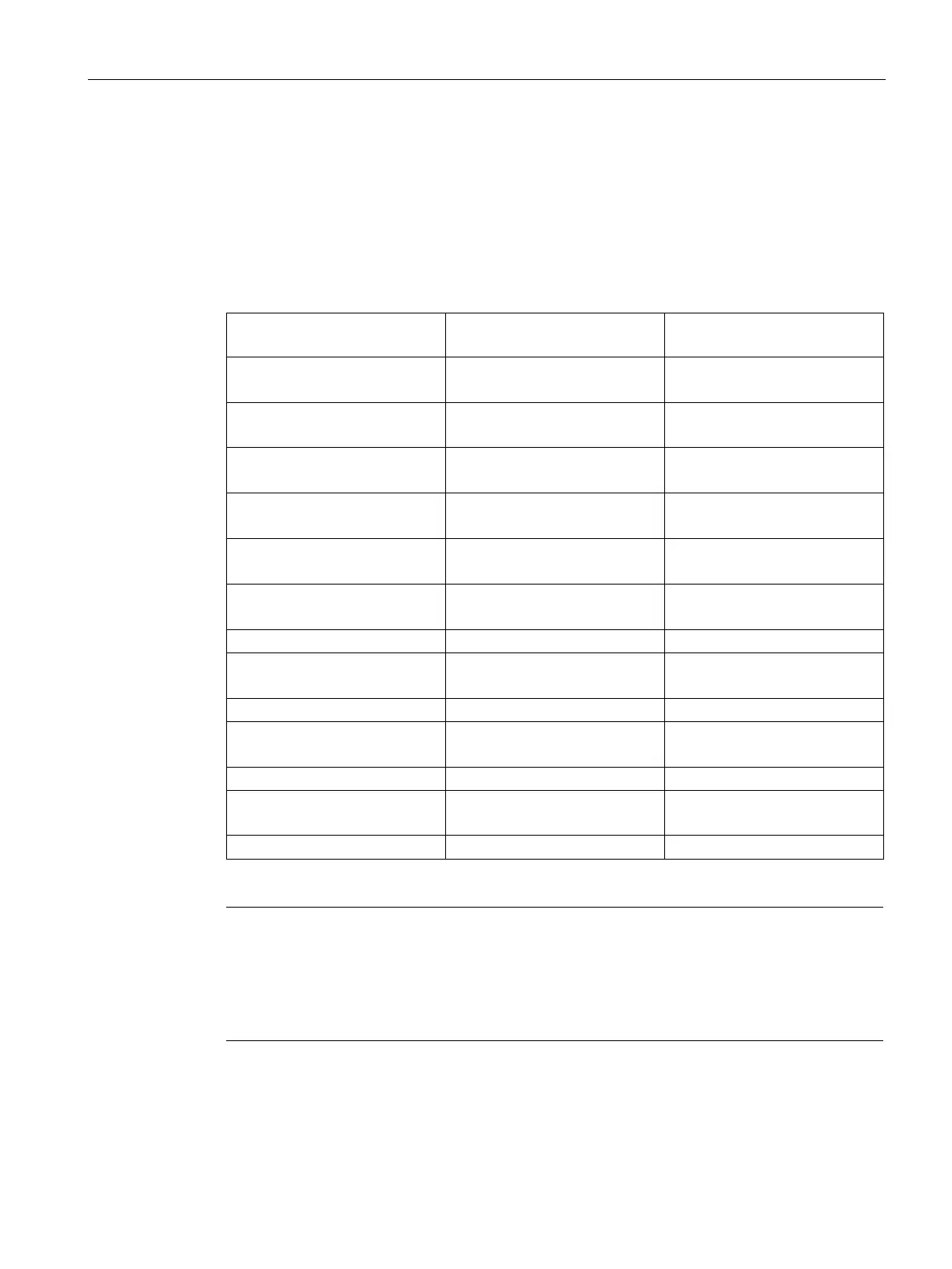

Screw material and tightening torques

Screws of varying strength classes are required to secure the motor to the machine

structure. The table below shows the required strength classes and tightening torques for the

stator and rotor fixing screws.

Table 5- 6 Required strength classes and tightening torques for the stator and rotor

Tightening torque

M

A

in Nm

1FW6050-xxB03-xxxx to

M6 (8.8) 9

1FW6060-xxB03-xxxx to

1FW6060-xxB15-xxxx

M6 (8.8) 9

1FW6090-xxB05-xxxx to

M5 (8.8) 5.2

1FW6130-xxB05-xxxx to

M5 (8.8) 5.2

1FW6150-xxB05-xxxx to

M6 (8.8) 9

1FW6160-xxB05-xxxx to

M8 (8.8) 21.6

1FW6190-xxB05-xxxx to

M8 (8.8) 21.6

1FW6230-xxB05-xxxx to

M8 (8.8) 21.6

1FW6290-xxB07-xxxx to

M10 (8.8) 43

Note

Underlying friction factor µ

ges

= 0.1

With lower friction values, the tightening torques may have to be reduced.

Also note the maximum tightening torques of the screws used.

These may be lower than the

values specified in the table above.

Loading...

Loading...