Programming and Operating Manual (Milling)

146 6FC5398-4DP10-0BA6, 09/2017

The following example is suitable for testing the parameterization of the TRACYL cylinder transformation:

Cutting edge position (Only for turning tools)

Length offset vector (Calculation acc. to t ype and plane)

Slot width b for slotting saw, roundin g radius for milling tools

Projection k (For slotting saw only)

Angle for taper milling tools

Length and radius compensation

Remaining parameters to $TC_DP24=0 (To ol base dimension/adapter)

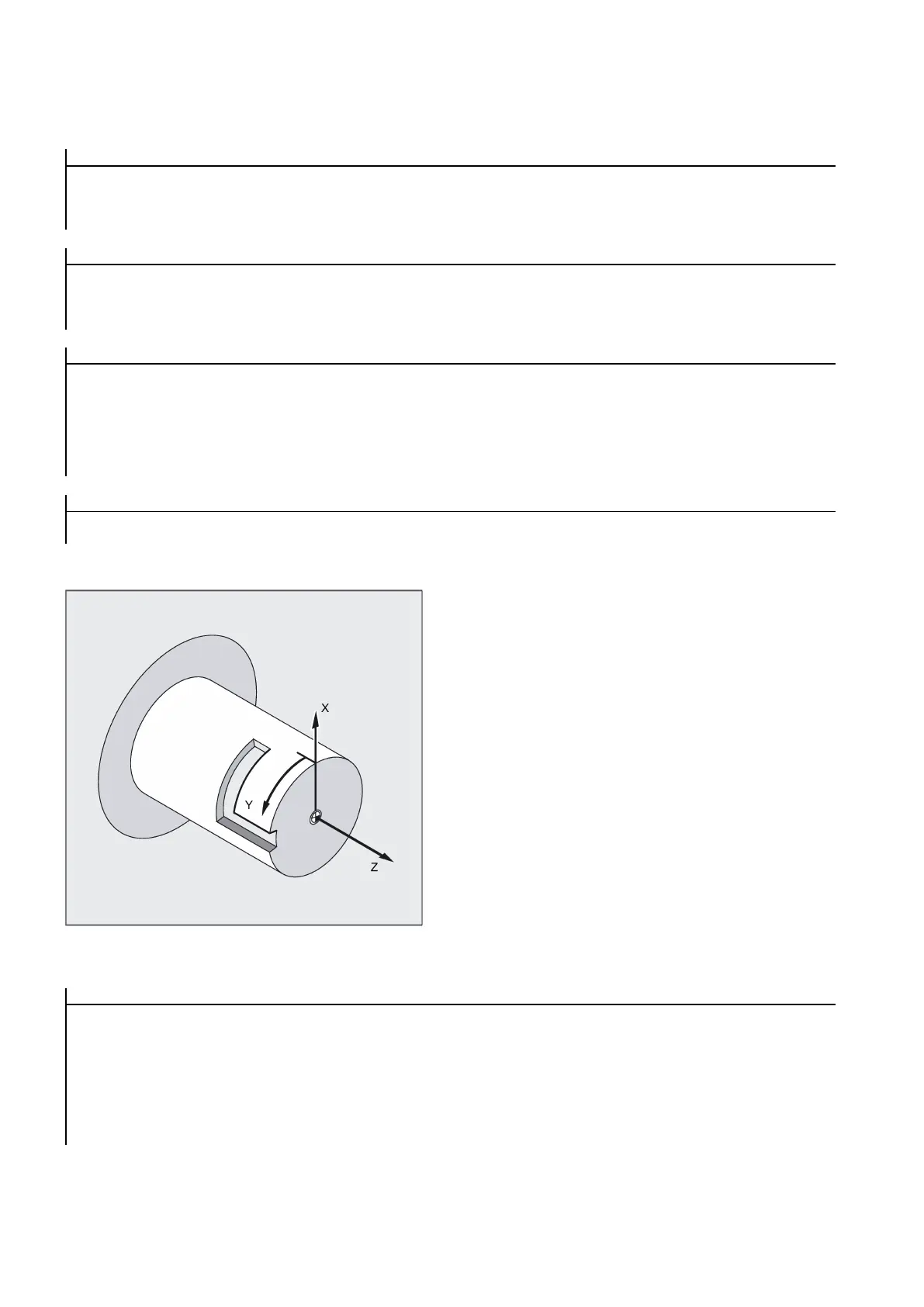

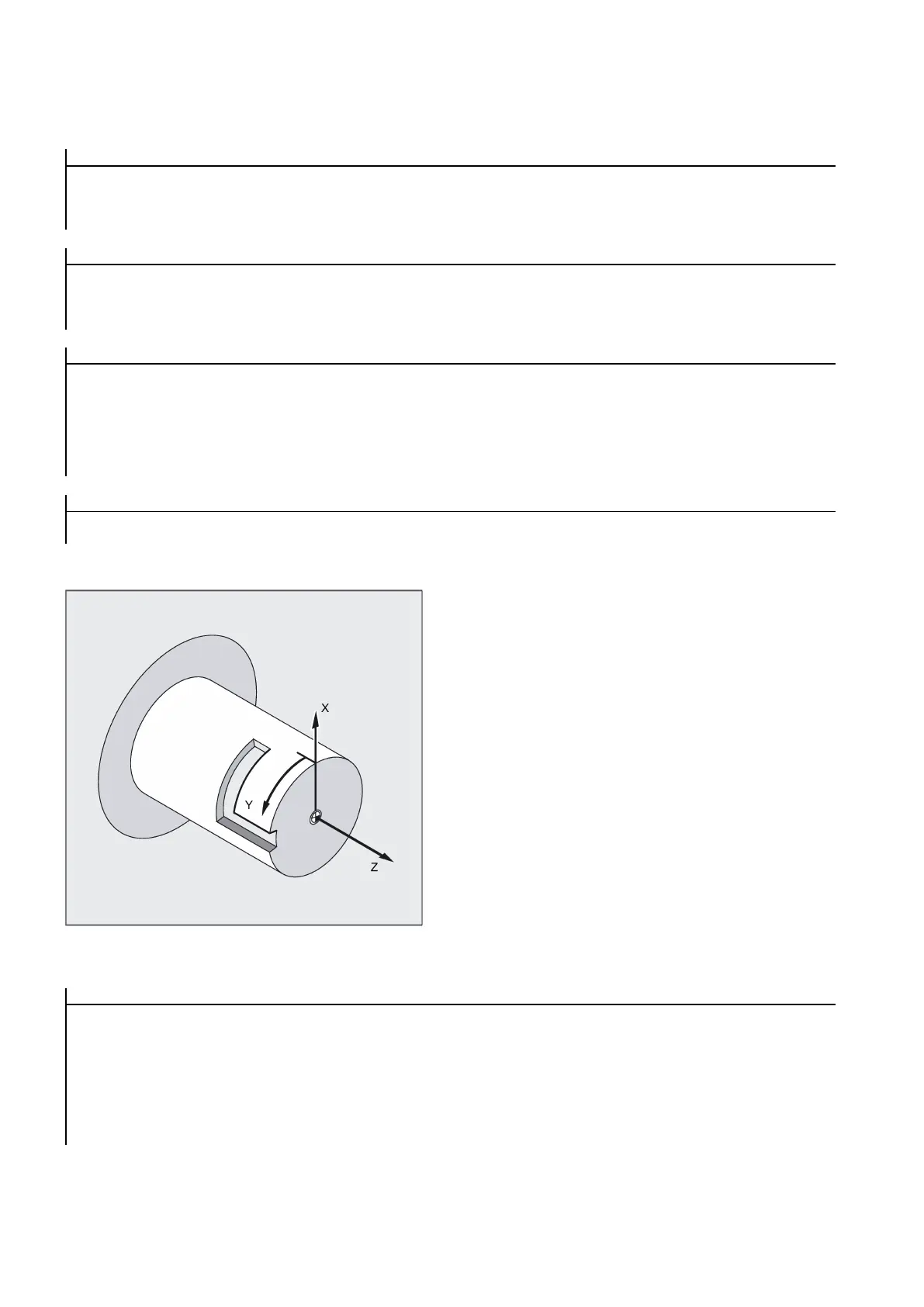

Example: Making a hook-shaped groove

Activate cylinder surface transformation:

Required tool: T1 milling tool, radius=3 mm, edge position=8

N10 T1 D1 G54 G90 G94

F1000

; Tool selection, clamping compensatio n

; Approach the starting position

; Set the second spindle as the main s pindle

; Change the diameter dimensio nin g to radius dimensioning

; Activate cylinder surface ;transform ation

Loading...

Loading...