Expanding the Operator Interface (BE1) 08/2005

8 Terms, Tables, Lists, Examples

© Siemens AG, 2005. All rights reserved

BE1/8-202 SINUMERIK 840D sl/840D/840Di/810D HMI Installation and Start-Up Guide (IAM) – 08/2005 Edition

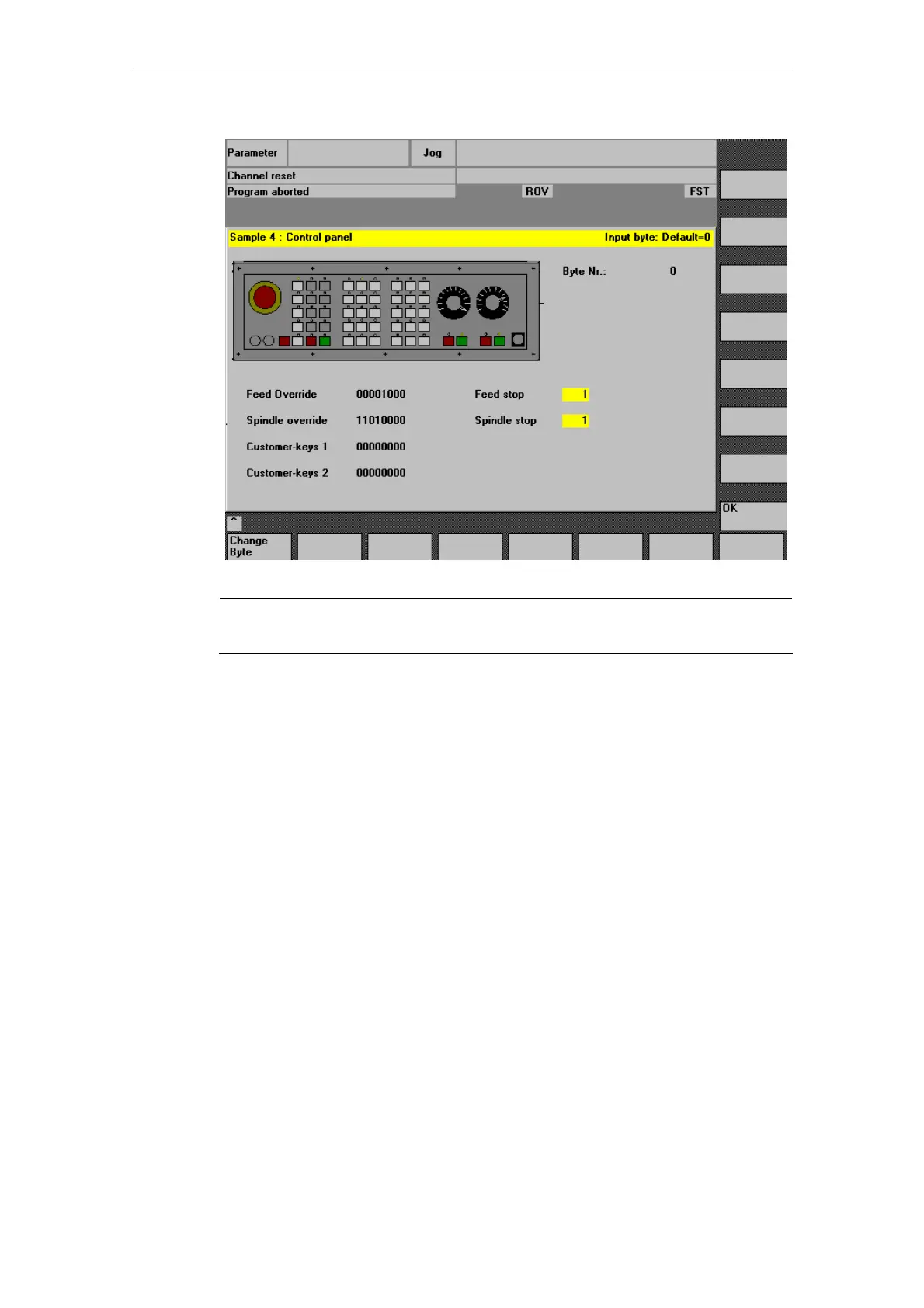

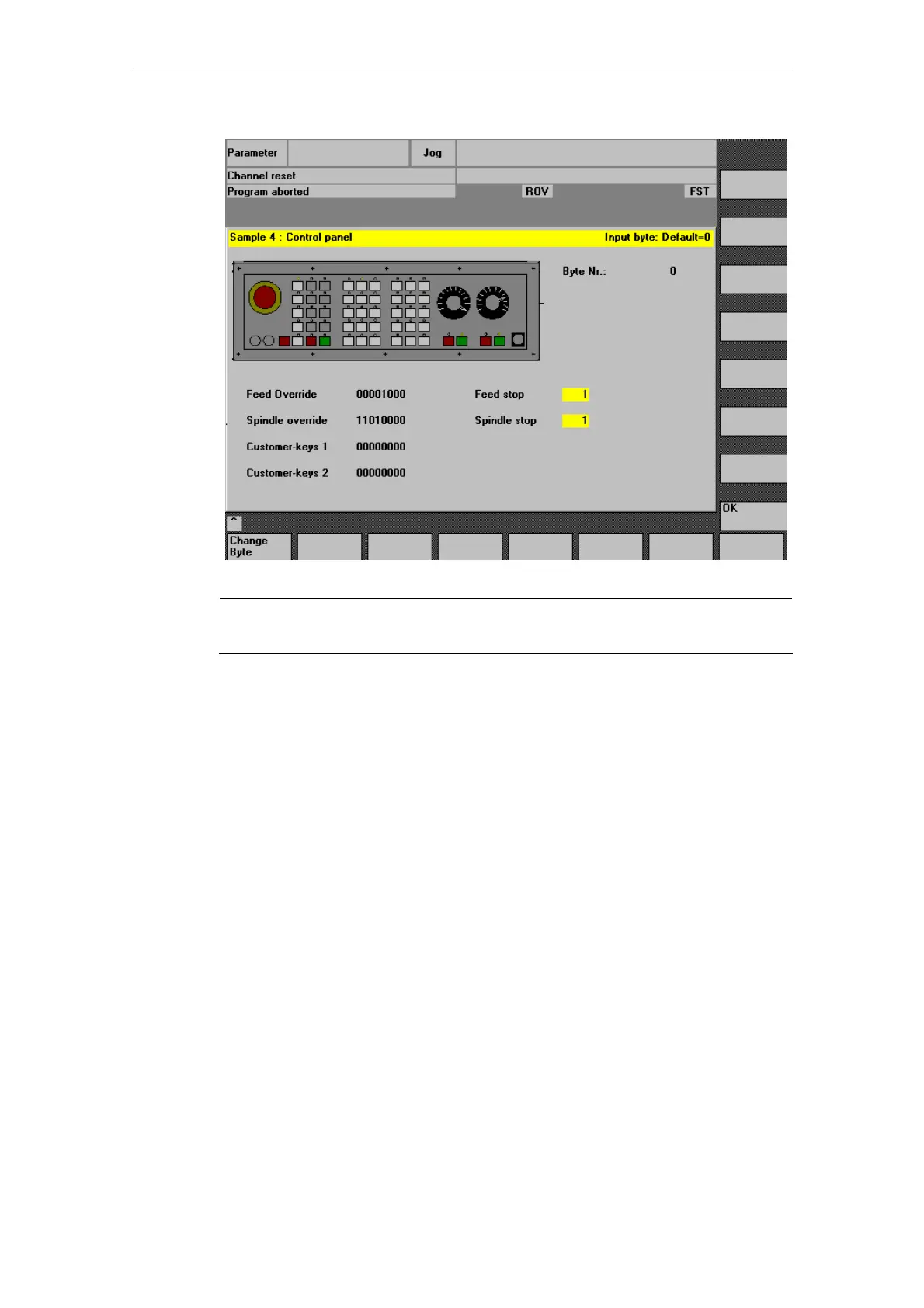

Fig. 8-1 Machine control panel

Note

You will find further examples in the supplied tool box.

Loading...

Loading...