Post Processing 57

off the 3Z Base and remove the plate from the heater. Typically this process can take

between 20 – 30 minutes.

4. Once the 3Z Base plate cools, it is ready for re-use on the unit.

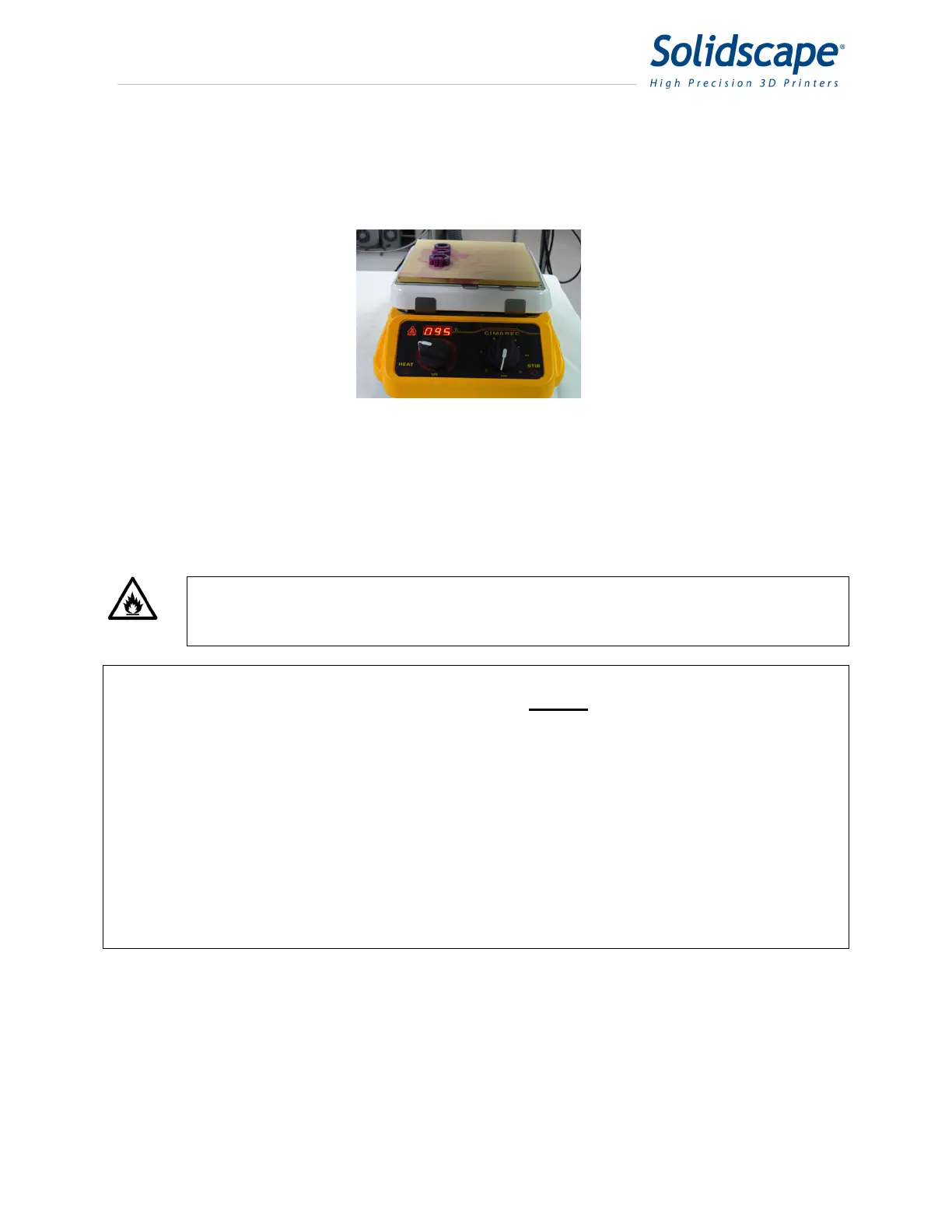

Figure 11-2 Heater Stirrer with build plate

11.4 Dewax – 3Z Support Material Removal

CAUTION! VSO is flammable. Never exceed maximum temperatures

specified. Use in a well ventilated area. Use care around heat

sources.

Note 1: The 3Z Model material is dimensionally stable at room temperature. However, it will

expand at temperatures in excess of 55 C. NEVER dewax models in a solvent

bath at temperatures above 55 C.

Note 2: The 3Z Support material exhibits a slightly higher rate of thermal expansion than the

3Z Model build material. Hollow model structures in which the build material

surrounds the support material can crack when heated in the solvent. To prevent

this from occurring, remove some of the support material with a pointed knife or drill

bit prior to immersion in the solvent bath. By creating a hollow in the support

material, it collapses inward when it expands, without cracking the surrounding

model.

Note 3: Many model geometries are very fragile even at room temperatures. Handle models

with care.

1. Once the model is removed from the 3Z Base, place the model into the basket strainer and

then place the strainer into VSO bath prepared in step 1.2. Use caution to position the

model in the strainer such that it is not resting on a delicate feature.

2. Turn the digital alarm thermometer on; insert the temp probe into the basket with the models

being careful to not hurt the models. Set the temperature alarm on the thermometer to 55°C

3. Set the stirrer control on the heater stirrer to a setting that will gently circulate the bath

without creating a lot of turbulence; the models should not be moving around in the strainer

Loading...

Loading...