Certification for the Inverter 12-7

605C Frequency Inverter

Requirements for UL Compliance

Solid-State Motor Overload Protection

These devices provide Class 10 motor overload protection. The maximum internal overload

protection level (current limit) is 150% for 60 seconds, and for quadratic torque 110% for 10

seconds. Refer to Chapter 6: Programming Your Application - I*t TRIP for user current limit

adjustment information.

An external motor overload protective device must be provided by the installer where the motor

has a full-load ampere rating of less than 50% of the Inverter output rating.

Short Circuit Rating

All models of this Inverter are suitable for use on a circuit capable of delivering not more than

10,000 RMS Symmetrical Amperes, 460V maximum.

Solid-State Short-Circuit Protection

These devices are provided with Solid-State Short-Circuit (output) Protection. Branch circuit

protection requirements must be in accordance with the latest edition of the National Electrical

Code NEC/NFPA-70.

Recommended Branch Circuit Protection

It is recommended that UL Listed (JDDZ) non-renewable cartridge fuses, Class K5 or H; or UL

Listed (JDRX) renewable cartridge fuses, Class H, are installed upstream of the Inverter. Refer

to Chapter 11: “Technical Specifications” - Power Details for recommended fuse ratings.

Motor Base Frequency

The motor base frequency rating is 480Hz maximum.

Field Wiring Temperature Rating

Use 75°C Copper conductors only.

Field Wiring Terminal Markings

For correct field wiring connections that are to be made to each terminal refer to Chapter 3:

“Installing the Inverter” - Power Wiring Connections, and Control Wiring Connections.

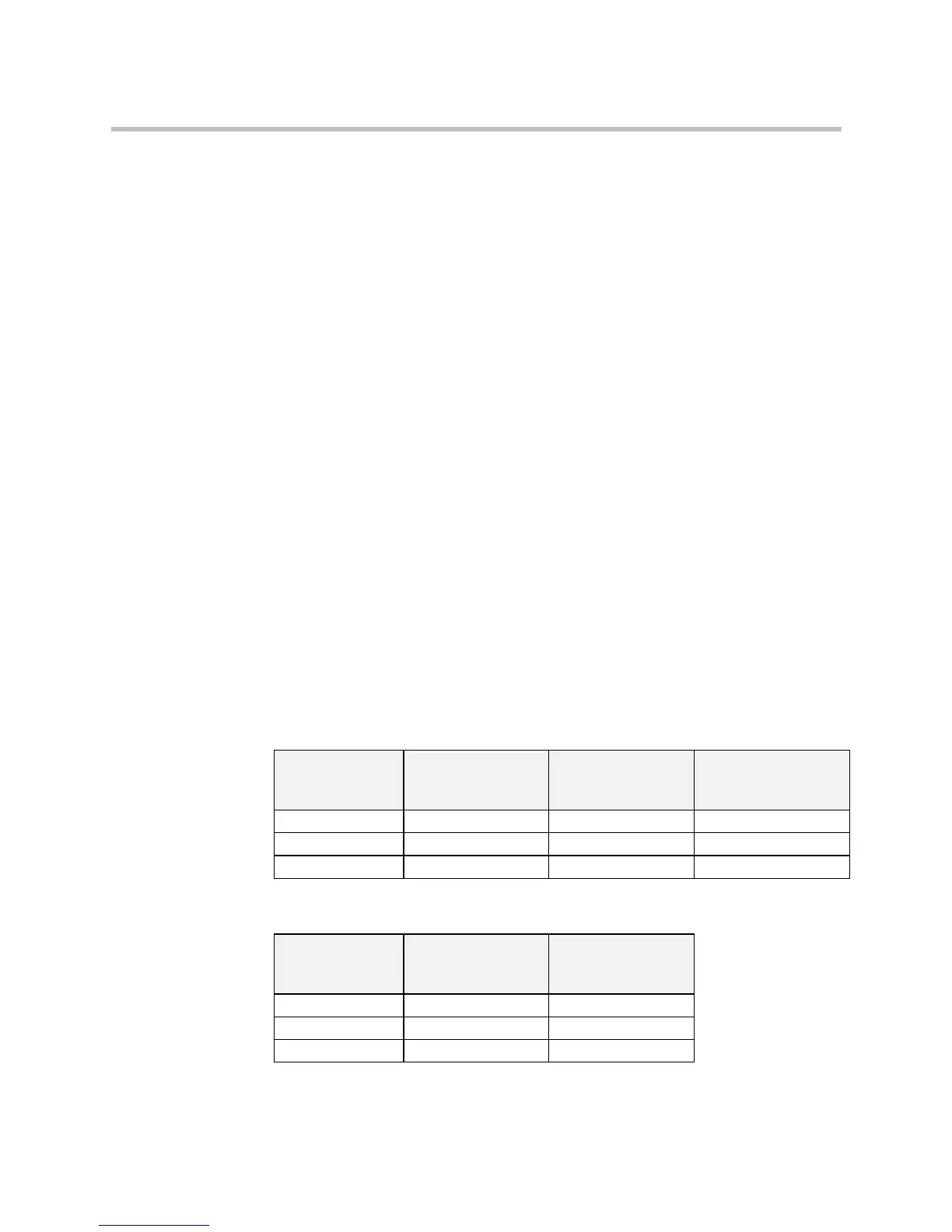

Power Wiring Terminals

Model Recognition

Product Code

(Block 2 & 3)

Power Terminals

(maximum wire size)

Brake Terminals

(maximum wire size)

Thermistor Terminals

(maximum wire size)

0055/400 12 AWG (3.3mm²) 12 AWG (3.3mm²) 12 AWG (3.3mm²)

0075/400 8 AWG (8.4mm²) 12 AWG (3.3mm²) 12 AWG (3.3mm²)

0110/400 8 AWG (8.4mm²) 12 AWG (3.3mm²) 12 AWG (3.3mm²)

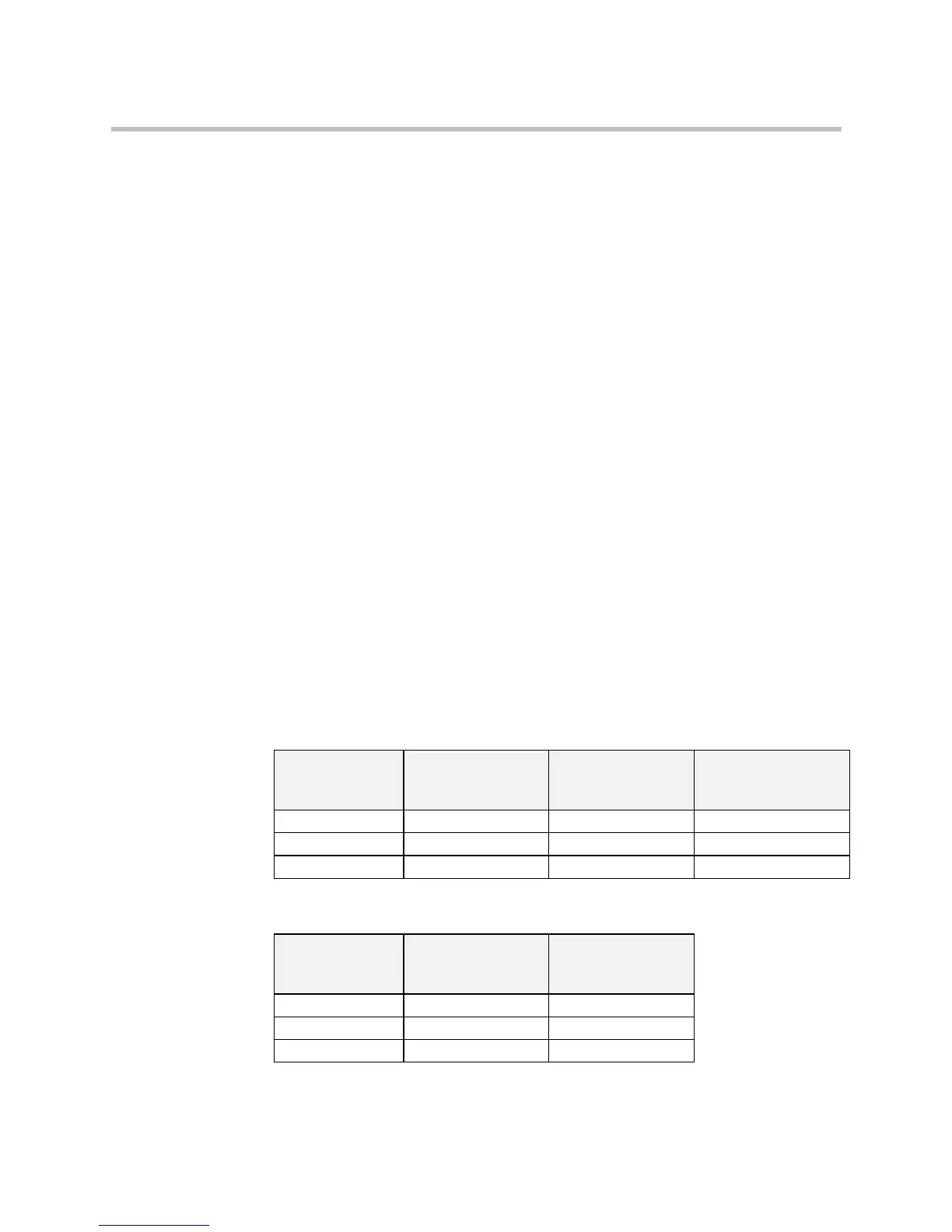

Terminal Tightening Torque

Model Recognition

Product Code

(Block 2 & 3)

Power Terminals

(lb-in)

Brake Terminals

(lb-in)

0055/400 12 12

0075/400 16 12

0110/400 16 12

Loading...

Loading...