102 TS 500i

11.6 Leak testing

11.6.1 Checking the fuel tank /

fuel system

On testing the fuel system under

pressure using the pressure testing

tool 5910 890 4100, a quick first test

can be carried out.

– Open the filler cap and drain the

fuel tank in accordance with

regulations, b 1

– Close the filler cap

– Remove the shroud, b 6.4

– Remove the control unit, b 7.3

– Remove the air filter, b 11.1

– Remove the tank vent, b 11.6.3

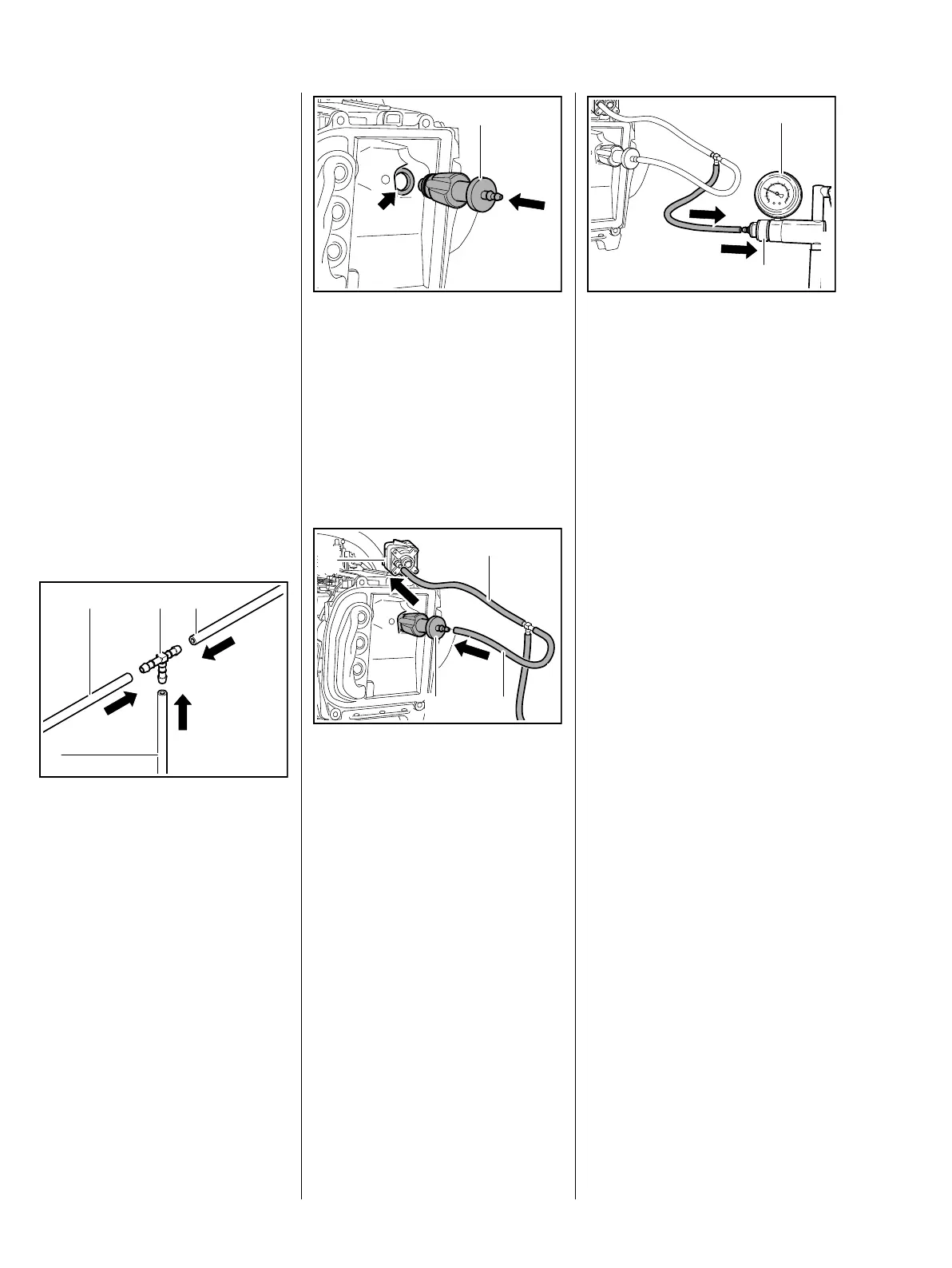

: Push the hoses (1)

1127 358 7600 onto connecting

element (2) 5910 895 0200

1307RA199 TG

2 11

1

– Coat O-ring on the plug with

STIHL press fluid, b 13

: Press the plug (1) of the pressure

testing tool 5910 890 4100 as far

as it will go into the hole (arrow)

– Pull injection pump from the

guide

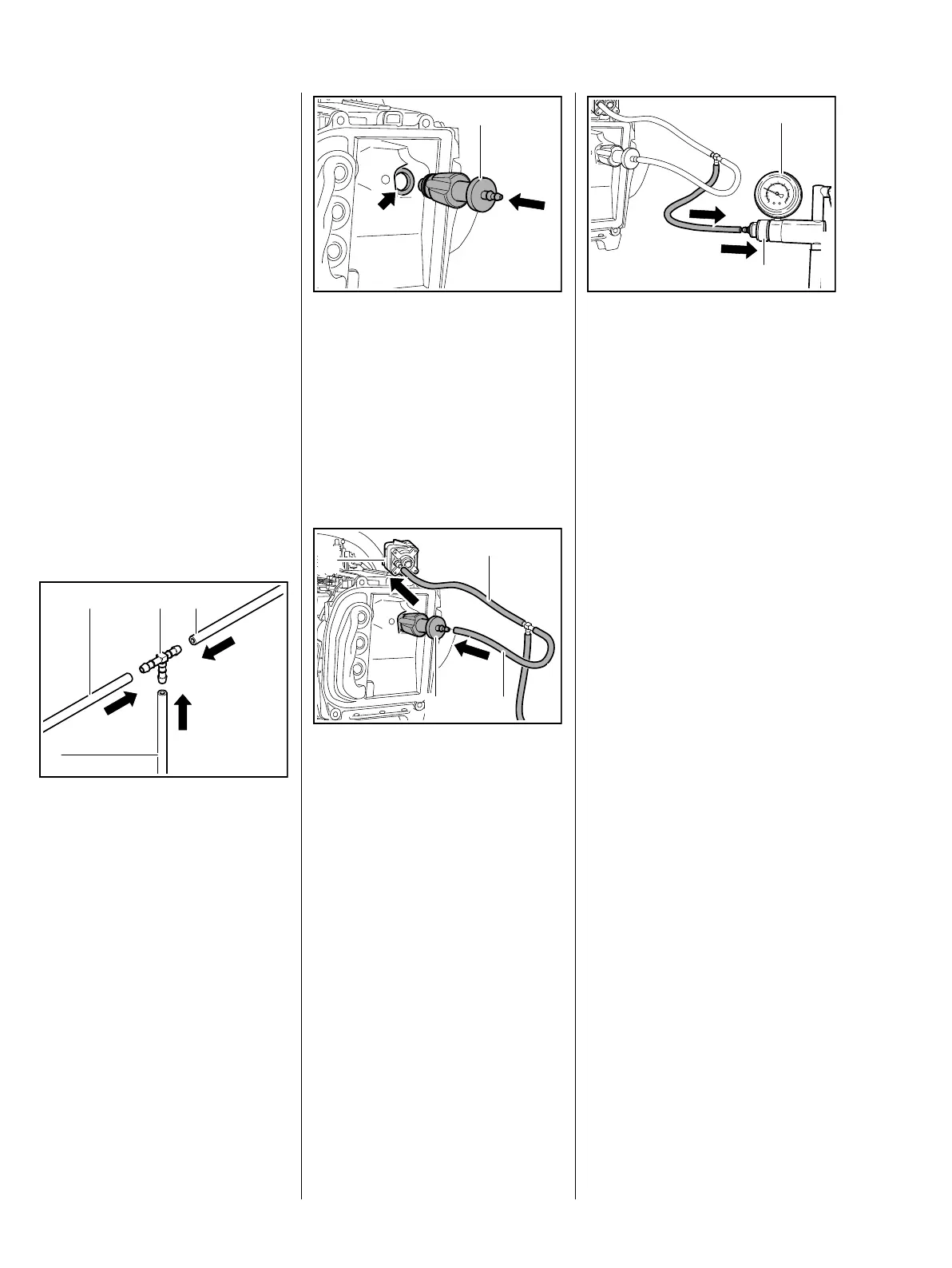

: Push hoses (1) 1127 358 7600

onto the plug (2) of the pressure

testing tool 5910 890 4100 and

injection pump (3)

1

1307RA370 TG

1307RA371 TG

1

2

3

1

: Slide ring (1) to the right and

connect the pump (2)

0000 850 1300 to the hose

– Build up gauge pressure in the

fuel tank

Actuate the pump until the pressure

gauge shows a pressure of 0.8 bar.

If this pressure remains constant for

at least 20 seconds, the tank is

airtight. If the pressure drops, the

leak must be located and the faulty

part replaced.

– After testing, slide the ring on the

pump to the left to vent the pump

– disconnect the hose.

– Remove pressure testing tool

– If the fuel tank is airtight, continue

with tank vent test, b 11.6.2

– Fit air filter, b 11.1

– Reassemble remaining parts in

reverse order

1307RA369 TG

1

2

Loading...

Loading...