42 TS 500i

6. Engine

6.1 Muffler / spark arresting

screen

– Refer also to troubleshooting

chart, b 3.5

– Remove the "cast arm with

guard", b 4.2

To keep dirt particles from entering

the cylinder, move piston to top

dead center before removing the

muffler.

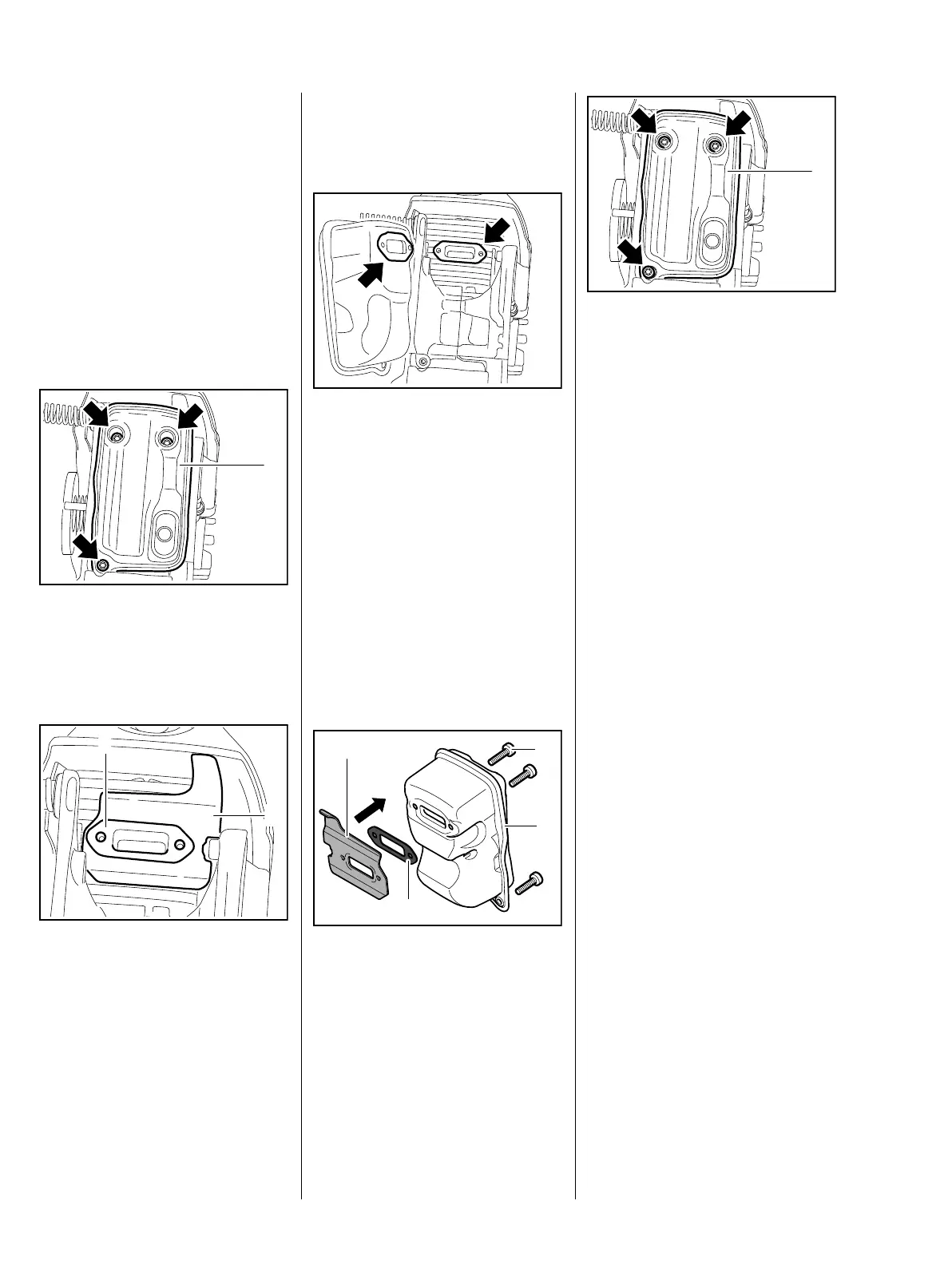

: Take out the screws (arrows)

: Take out and examine the

muffler (1), replace if necessary

: Remove the muffler gasket (1)

and cooling plate (2)

1

370RA083 TG

2

1

370RA084 TG

– Installing and removing the spark

arresting screen, see Instruction

Manual

– Cover exhaust bore and remove

any fouling on the cylinder and

exhaust bore

: Examine and clean the mating

surfaces (arrows) on the exhaust

bore, cooling plate and muffler,

remove any gasket residues if

necessary – there must not be

any gasket residues or dirt

particles in the exhaust bore,

b 13

Parts with damaged mating faces

must be replaced.

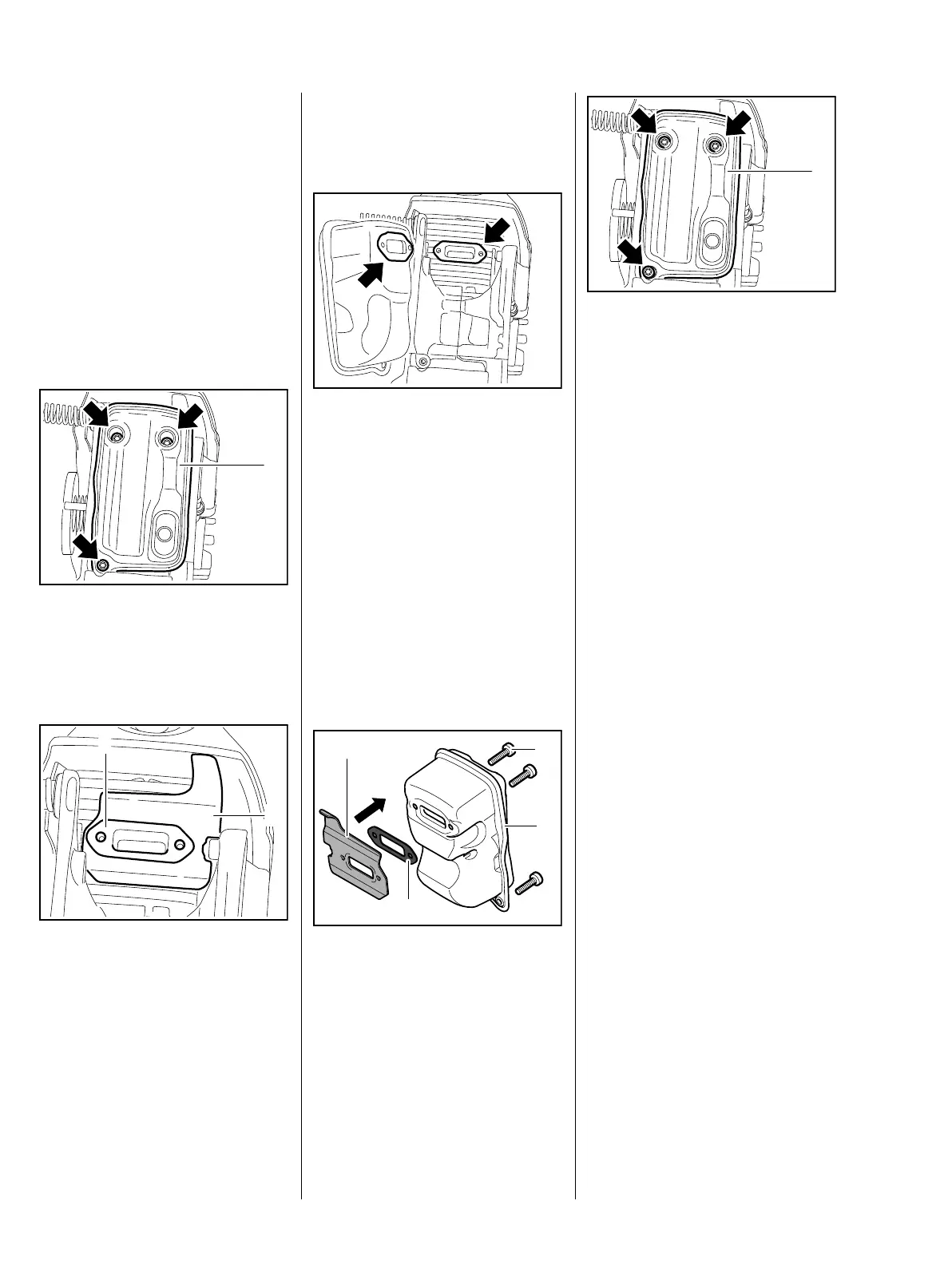

: Fit cooling plate (1) and muffler

gasket (2) to muffler (3) and

insert screws (4) into cooling

plate

– Muffler gasket and cooling plate

are held in place on the muffler

1307RA062 TG

1

2

3

4

: Carefully fit muffler (1) with

muffler gasket and cooling plate

: Fit the screws (arrows) and check

that the cooling plate and gasket

are correctly positioned

: Insert the screws (arrows) and

tighten them according to

specifications, b 2.5

6.2 Leak testing

Defective oil seals and gaskets or

cracks in housing are the usual

causes of leaks. Such faults allow

supplementary air to enter the

engine and upset the fuel-air

mixture.

This can above all affect the idle

speed.

Moreover, it is possible that the

transition from idle speed to part or

full throttle is not smooth.

Always start with the vacuum test

and then continue with the pressure

test.

The engine can be thoroughly

checked for leaks under vacuum

and at gauge pressure using the

pump 0000 850 1300.

1

370RA088 TG

Loading...

Loading...