52

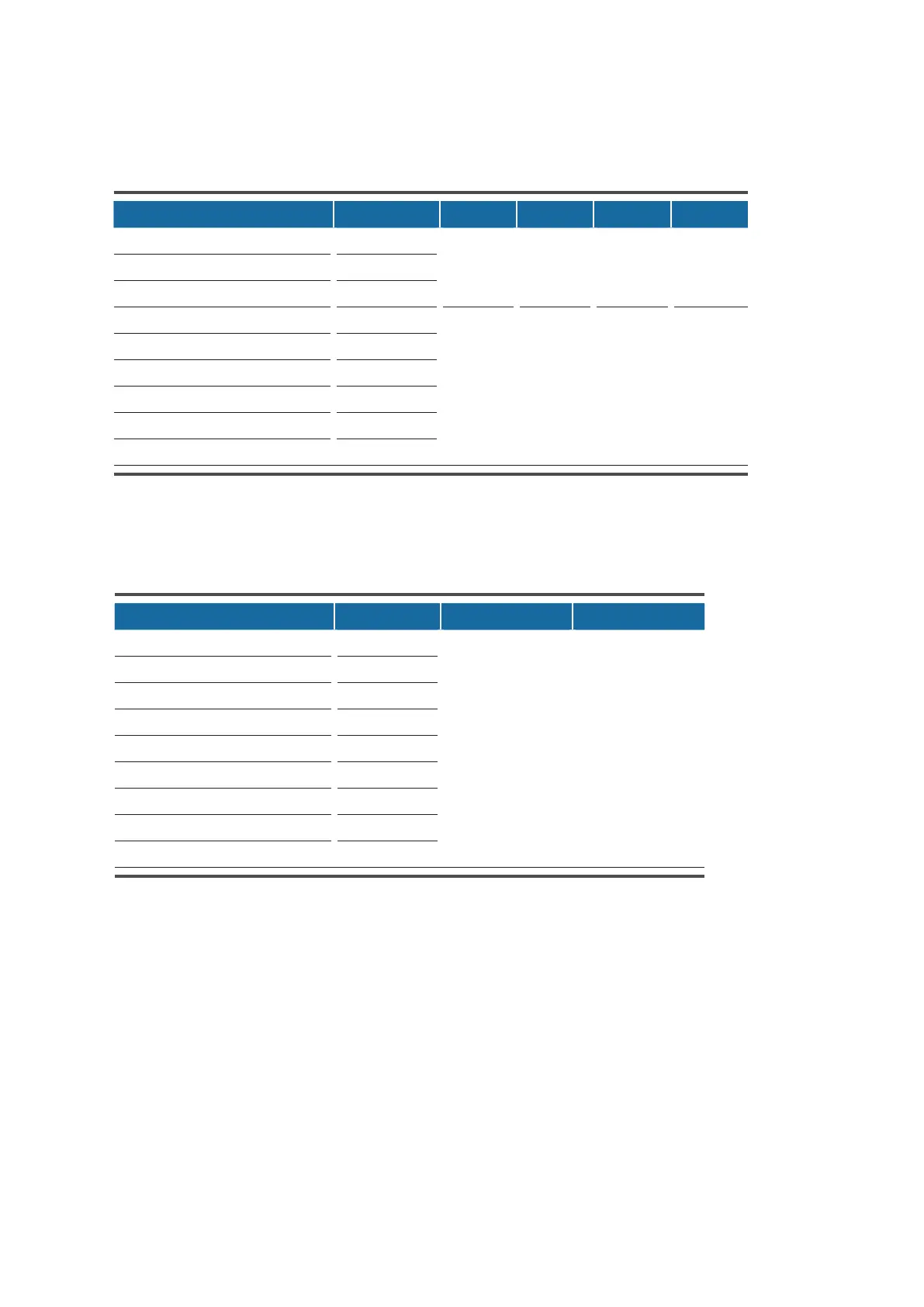

Kompressormodell Kältemittel vd1 [bar] kd1 [bar] vd2 [bar] kd2 [bar]

Mitsubishi ANB33 R410A

6,0 12,8 17,0 32,6Mitsubishi ANB42 R410A

Mitsubishi ANB52 R410A

Copeland ZP182KCETFD R410A

10,0 16,5 14,0 21,0

Copeland ZP154KCETFD R410A

Copeland ZP137KCETFD R410A

Copeland ZP120KCETFD R410A

Copeland ZP103KCETFD R410A

Copeland ZP90KCETFD R410A

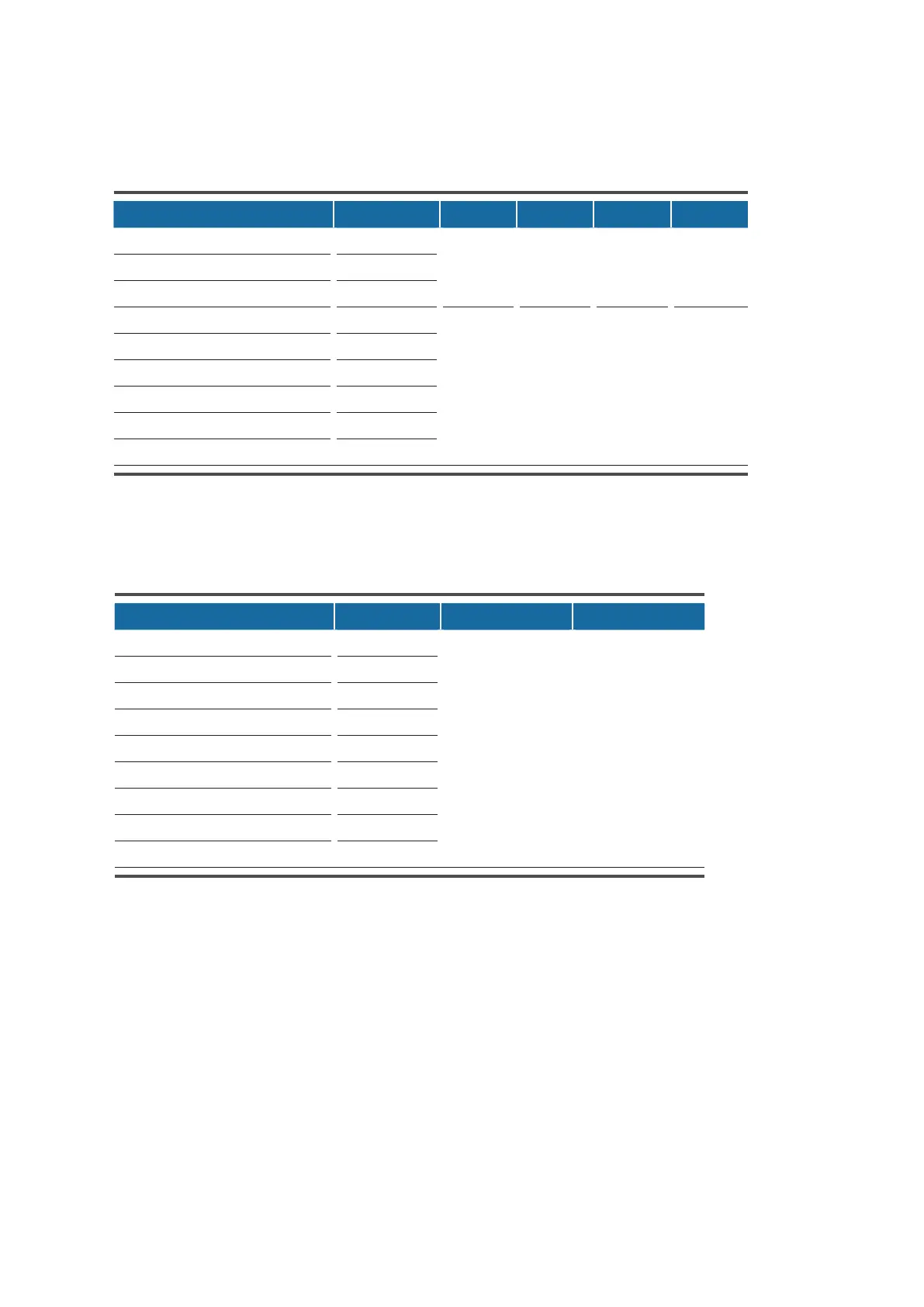

Kompressormodell Kältemittel MIXSollwert [bar] DXSollwert [bar]

Copeland ZP83KCETFD R410A

16,5 16,5

Copeland ZP72KCETFD R410A

Copeland ZP61KCETFD R410A

Copeland ZP54KCETFD R410A

Copeland ZP42KCETFD R410A

Copeland ZP36KCETFD R410A

Copeland ZP31KCETFD R410A

Copeland ZP29KCETFD R410A

Copeland ZP24KCETFD R410A

EN/06.2019/G57 © STULZ GmbH – all rights reserved

C7000 INSTRUCTIONS fOR a/C UNITS

Application of dynamic condensation pressure control (parameter "dyn." = 1)

The table displays the recommended values in dependence of the compressor type and the refrigerant:

(up to now for refrigerant R410A only)

Due to the right-angled shape of the envelope in the pressure diagram, the configuration of a fix condensati-

on pressure setpoint is sufficient for the following compressor types. (parameter "dyn." = 0)

Compressor model Refrigerant ep1 [bar] cp1 [bar] ep2 [bar] cp2 [bar]

Compressor model Refrigerant MIX setpoint [bar] DX setpoint [bar]

Loading...

Loading...