55

t

t

E

A

t

t

E

A

K

P

= 10

k

K

P

= 1

DT = 0,3 K

t = 1 sec.

K

I

= 10

k

K

I

= 0,333

© STULZ GmbH – all rights reserved EN/06.2019/G57

C7000 INSTRUCTIONS fOR A/C UNITS

I-factor

actual val.

Set val.

P-factor

SP: Setpoint

E: input value, return air temp.

/ supply air temp. in general,

condensation pressure for

G-valve

A: output value, speed in general,

opnening degree for valves

A = K

p

PID control

For the following components you can adjust a PID control, consisting of a P-fac-

tor, I-factor and D-factor:

- ICC - Fan with differential temperature control

- HGBP valve - Louvers with DFC² control

- G-valve - Condenser fan with DFC² control

- GE/CW-valve - Pump in CPP units

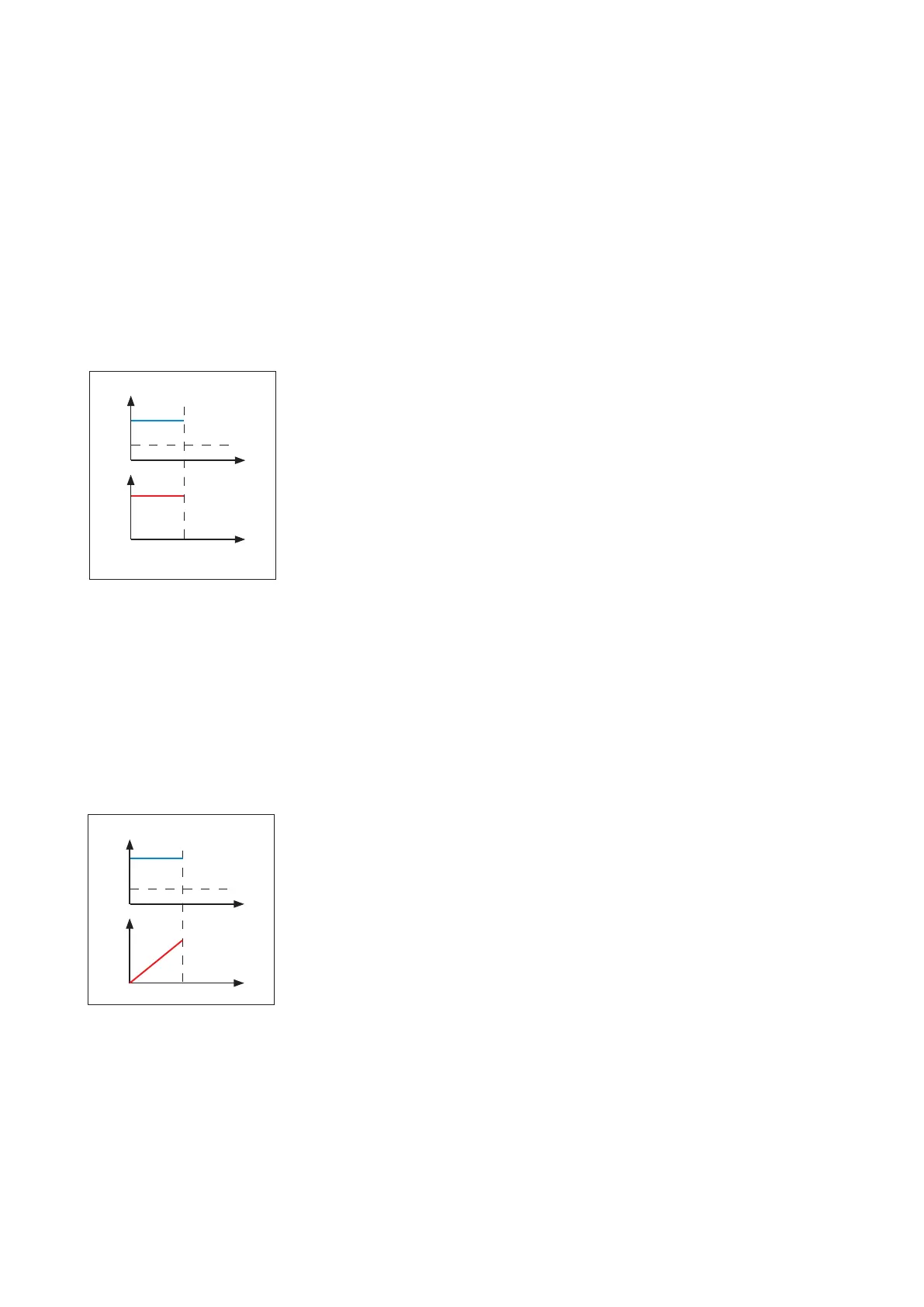

P factor

By the P factor you set the ratio of the output variable to the input variable differ-

ence (measured value minus setpoint).

To each deviation from the setpoint exists a fix output value for the component

which is to work against the deviation.

A characteristic of the proportional control is a permanent discrepancy of the input

variable to the setpoint as long as there is a disturbance variable.

With the help of an example the single parts (P-, I-, and D-part) shall be calculated

for a setpoint discrepancy of DT = 0,3 K for the GE/CW valve.

Example: T

set = 24°C

T

act = 24,3°C

j

P

= K

P

D

K

P

j

P

j

P

= 3 (opening degree in %)

DT = T

actset

DT = 0,3 K

P factor:

component depen-

dant constant:

I factor:

component depen-

dant constant:

actual val.

I factor

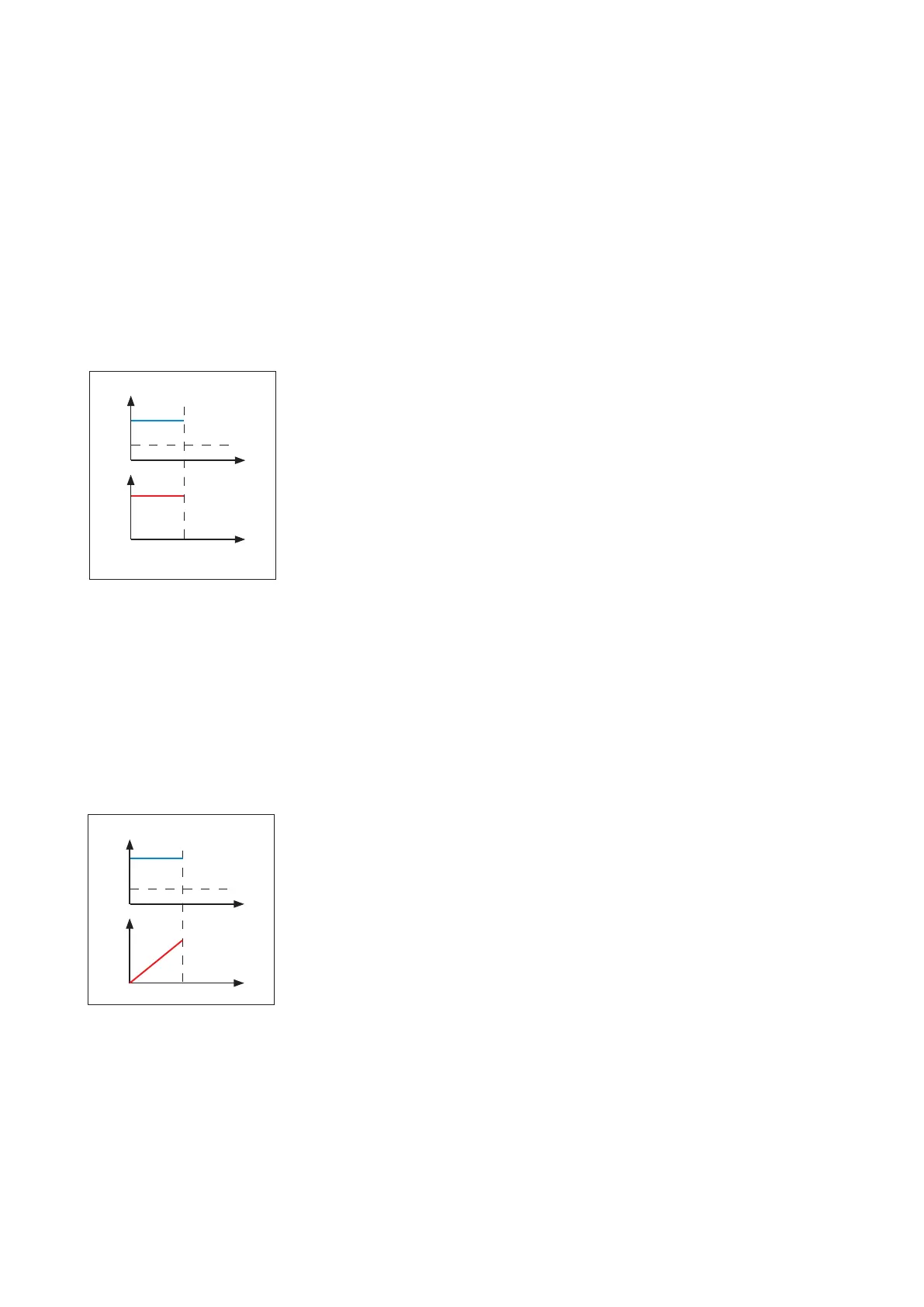

By the I-factor you adjust the integral part of the control. The integral part reacts to

a difference between actual (measured) value and set value with a constantly ris-

ing output. The bigger the difference, the faster increases the output. The integral

part serves to avoid a constant discrepancy from the set value. The more straight

away the control takes effect, the bigger the I-factor can be chosen.

Example:

for the ICC, if supply air control has been set.

The more storage elements (as for example big space volumes in case of return air

control) exist in the control loop, the smaller the I-factor must be chosen to avoid

an overshooting of the control loop.

Example: j

I

= K

I

D

K

I

j

I

j

I

= 1 (opening degree in %)

after 5 sec.:

j

I

= 5%

Loading...

Loading...