Aligna

®

4D User Manual

23 / 84

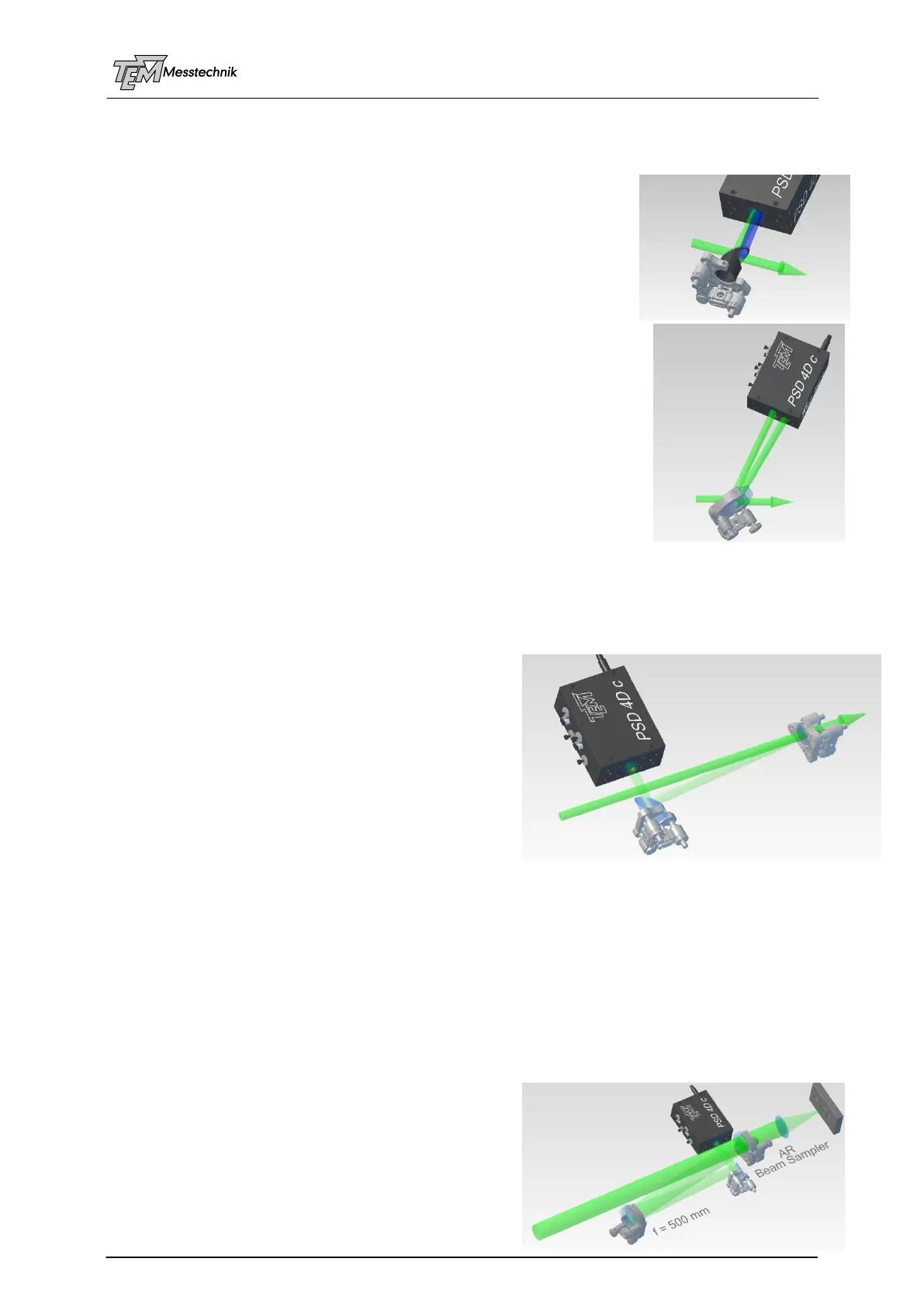

4.4.3.4 Short Distance Wedge Plate

If there is not enough space for this distance (especially, if the

beam diameter is large), the wedge plate can be oriented vice versa,

so the part beam from the front and from the back surface combine

approximately the position detector chip. Of course, there will ap-

pear interference fringes at the detector chip. However due to the

well-selected wedge angle these fringes are so narrow, that they

wipe out by integration over very many fringes.

(In this case, the wedge angle has to be selected rather carefully:

The focused spots at the angle detector chip have to be separated

distinctly more than the A chip size, while both un-focused spots at

the B chip should fit completely to the chip size.)

If the 2 x 0.9% reflectivity is too high (the 2% of power should not be

lost, or the sampled beam becomes very strong because of high laser

power) the sampler plate can be oriented at Brewster's Angle (about

57°) instead of 45°.

Because of the smaller angle, the demands on the surface quality of the sampler plate are

higher, and the size of the plate must be larger, compared to 45°. In addition, the sampled

beam comes out at a less convenient angle (compared to 90° with 45° plates).

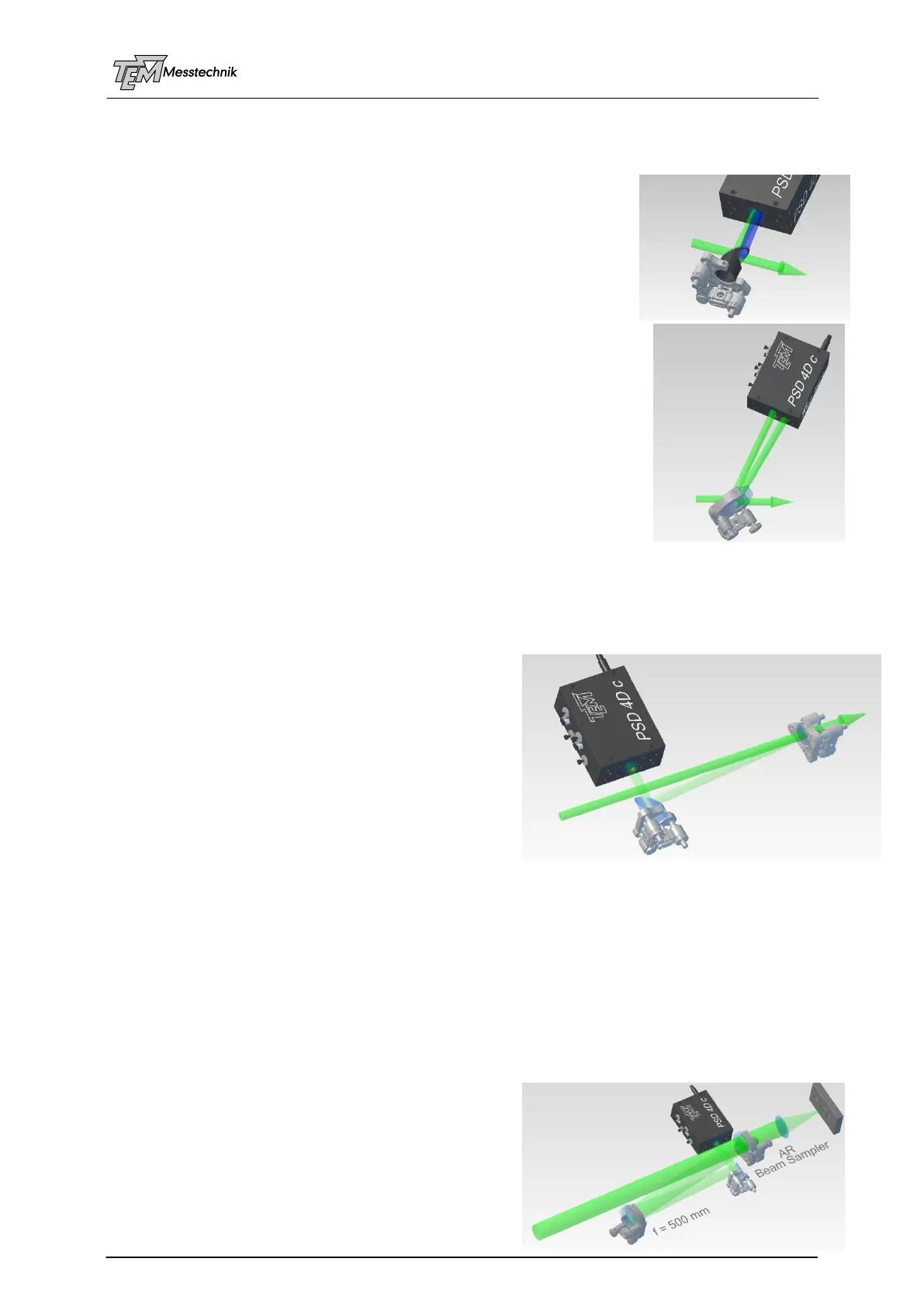

4.4.4 AR-Coated Windows at

Small Angle

The wedge plates (or un-wedged plates with ultra-

fast lasers) at 45° or larger angle have two draw-

backs:

1. The sampling is strongly dependent on the polari-

zation (p-light necessary!), and the out-coupling

might be too strong for high power lasers.

2. AR coatings at 45° are difficult to get from stock

and have much less assortment at most optics

suppliers.

Custom-made AR coated wedge plates (at 45°) are a solution. They can reduce the reflectivity

of the s-light from 12% down to 0.3% and of the p-light down to 0.1 % or so. However, they are

difficult to get from stock. Thus, they have to be specially coated, and therefore are rather

expensive and have a long lead-time.

Using commercially available AR coated windows (with or without wedge angle) are a practical

solution. They can be (and have to be) operated close to 0° angle of incidence (AOI). Typically

<12° is within the specs range of the coatings. An additional folding mirror helps avoiding too

long distance from the sampler to the detector, and allows for a convenient sample beam

alignment.

Due to the small AOI the polarization dependence is

negligible, so this setup also works fine for un-

polarized or randomly polarized lasers (for example

some fiber lasers, or lasers which have been guided

through a non-polarization-maintaining fiber, or

Loading...

Loading...