4.3 Restoring Operation from Position Detector Error

Make sure on the error display that a position detector error is generated. Identify the

type of the position detector error and position data on the encoder status display, then

perform each restoring operation.

4.3.1 Encoder Status Display

Call the encoder status screen on the teach pendant display, and make sure of the

position data and the type of position detector error there. The type of the position

detector error (i.e., error status) is expressed as shown below. The motor multi-turn

data, home position data within one (1) full turn of motor and error status are

displayed under the column of [MULTI], [SINGLE] and [Err-df], respectively.

To call the encoder status screen, observe the following procedures.

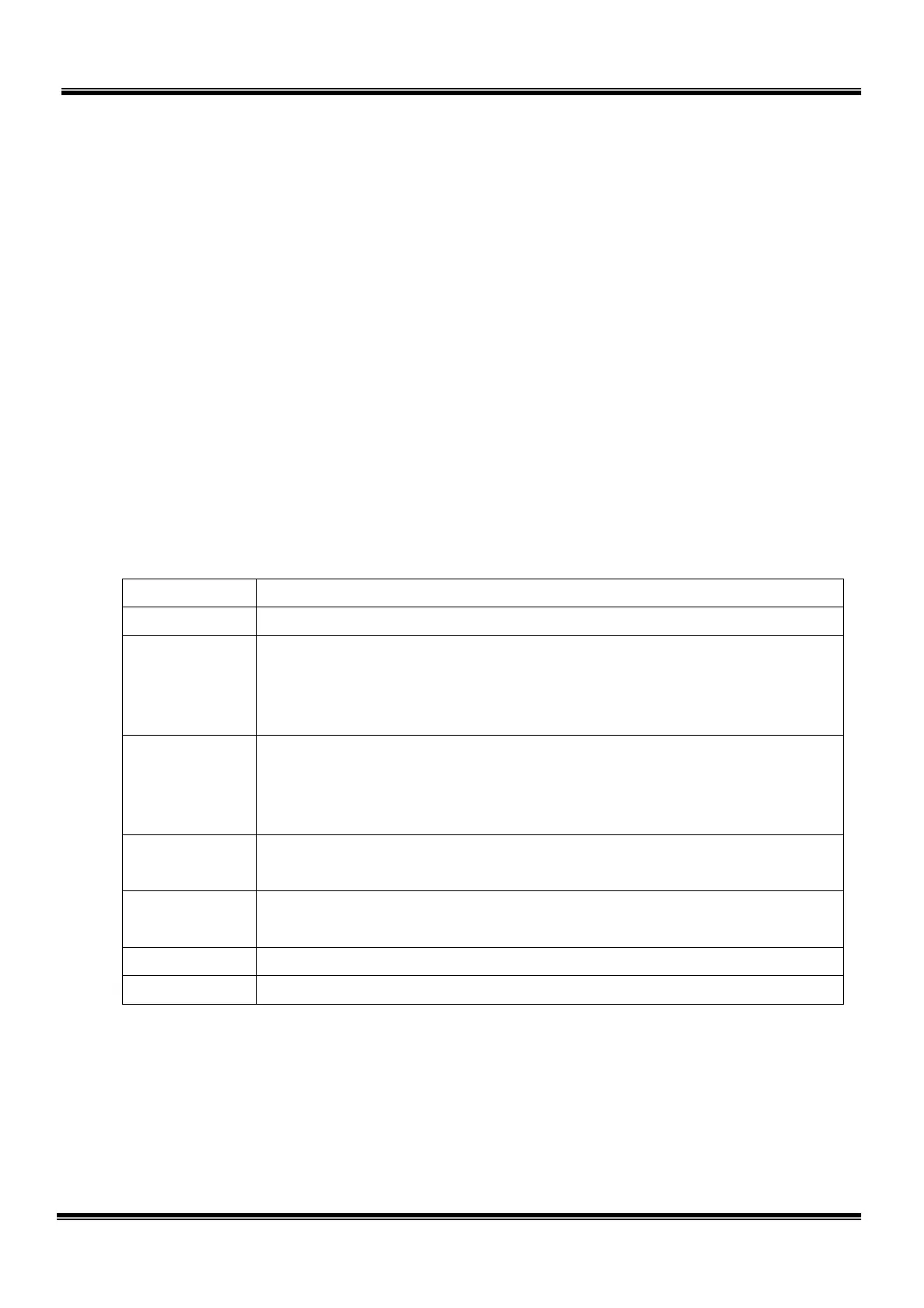

Table 4.1 Error status table

Error status Description

0000 Signifies the normal condition.

0100 This error occurs when a heavy vibration has been exerted on the

robot or when the robot has been moved fast by hand while the

power drive cable was disconnected during power OFF.

The multi-turn data has possibly shifted.

0200 Because axis feed was not executed after power ON, the encoder

resolution has deteriorated. During axis feed, the encoder

resolution returns to normal.

No alarm will generate.

8000 The battery voltage has dropped.

Replace the batteries.

4000 The battery voltage has dropped further than the above.

An error has possibly occurred in the multi-turn data.

4200 Errors 4000 and 0200 have occurred at the same time.

C200 Errors 8000, 4000 and 0200 have occurred at the same time.

STE 85306

– 98 –

Loading...

Loading...