1.2 Items for Maintenance and Inspection

This section describes the items for maintenance and inspection.

For the executing procedures, see the relevant paragraph listed in the table below.

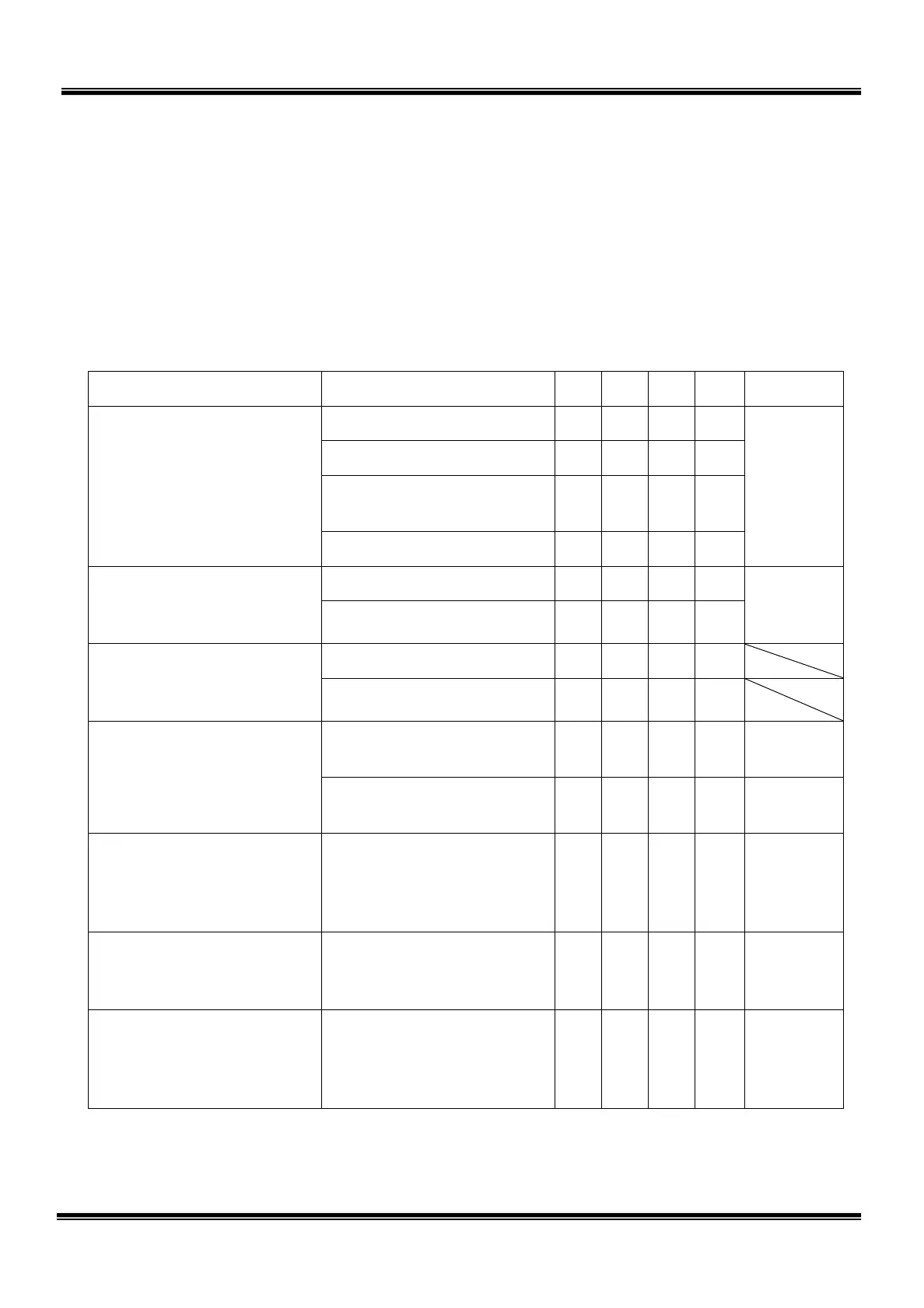

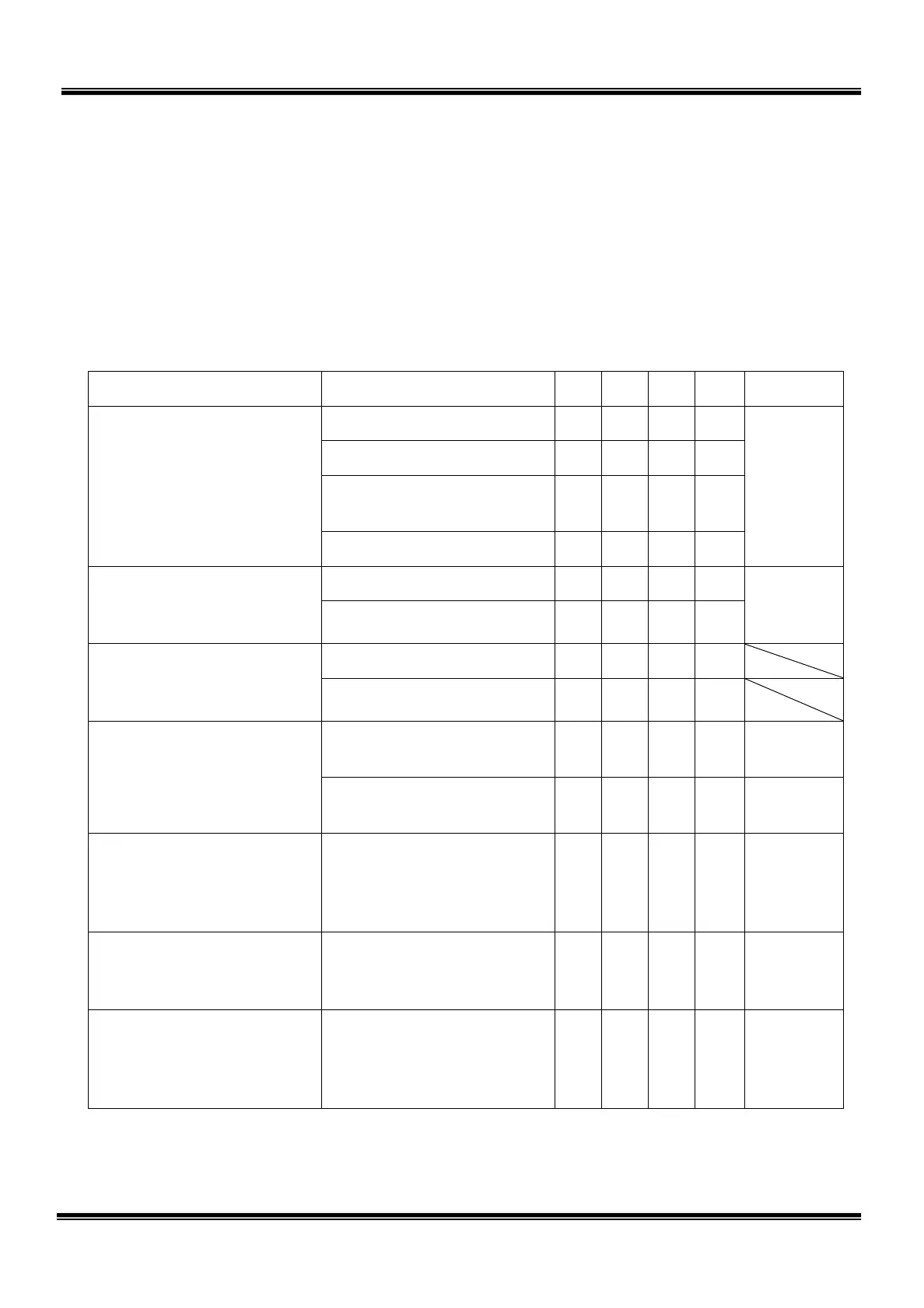

1.2.1 Inspection at Power OFF (at Non-Operation)

D: Daily inspection Q: Quarterly inspection

S: Semi-annual inspection A: Annual inspection

Description Check position D Q S A Refer to

Make sure that all bolts

are completely tightened

tighten the bolts

completely.

Tool set bolts

Para.

2.2.1

Robot installation bolts

Bolts for each joint

reduction gear

Motor set bolts

Make sure that all

connectors are tightened

completely.

Base connector

Para.

2.2.2

External wiring for axis 5

Make sure that no cut or

scratch is found. Clean

the contaminant, if any.

Entire robot

Arm 2 interior

Make sure that enough

volume of grease is filled.

Otherwise, fill the grease.

Ball screw shaft

Para.

2.7.3

Reduction gear interior

Para.

2.8.3

Make sure that each

timing belt is not worn off

or cracked. Check each

timing belt for tension.

Arm 2 interior

Para.

2.6.5

Make sure that the cables

and air tubing are not

worn out.

Cables and air tubing of

each unit

Para.

2.2.3

Make sure that each axis

can be operated properly

by moving the axis by

hand.

Entire robot

Para.

2.2.4

STE 85306

– 12 –

Loading...

Loading...