2.8.5 Mounting Axis 1 Reduction Gear

• Handle the reduction gear with extreme care. If it drops or an unusually large

external force is exerted on it, the reduction gear cannot function any further.

• Use the center gear which is attached to the new reduction gear.

If the old center gear is u

sed as it is, abnormal noise will be caused, the service

life will shorten or positioning accuracy will deteriorate due to incompatibility

with the new reduction gear.

• Also use the “O” ring attached to the new reduction gear. Be sure to set the

“O” ring. Unless the “O” ring is set, grease will leak from the axis 1 reduction

gear set surface. When mounting the reduction gear, take careful precautions

not to break the “O” ring.

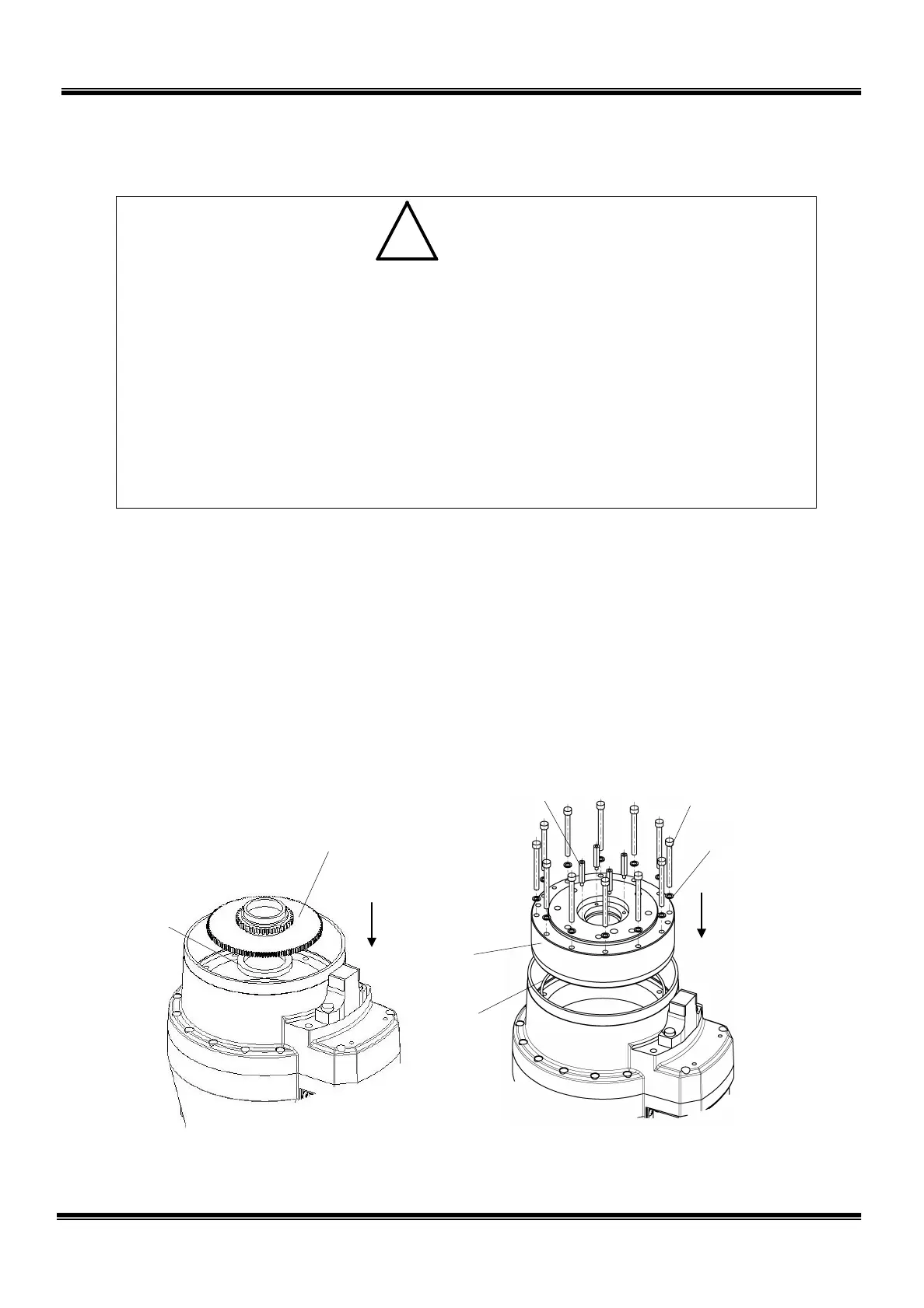

1) Mount the new bearing, and center gear attached to the new reduction gear.

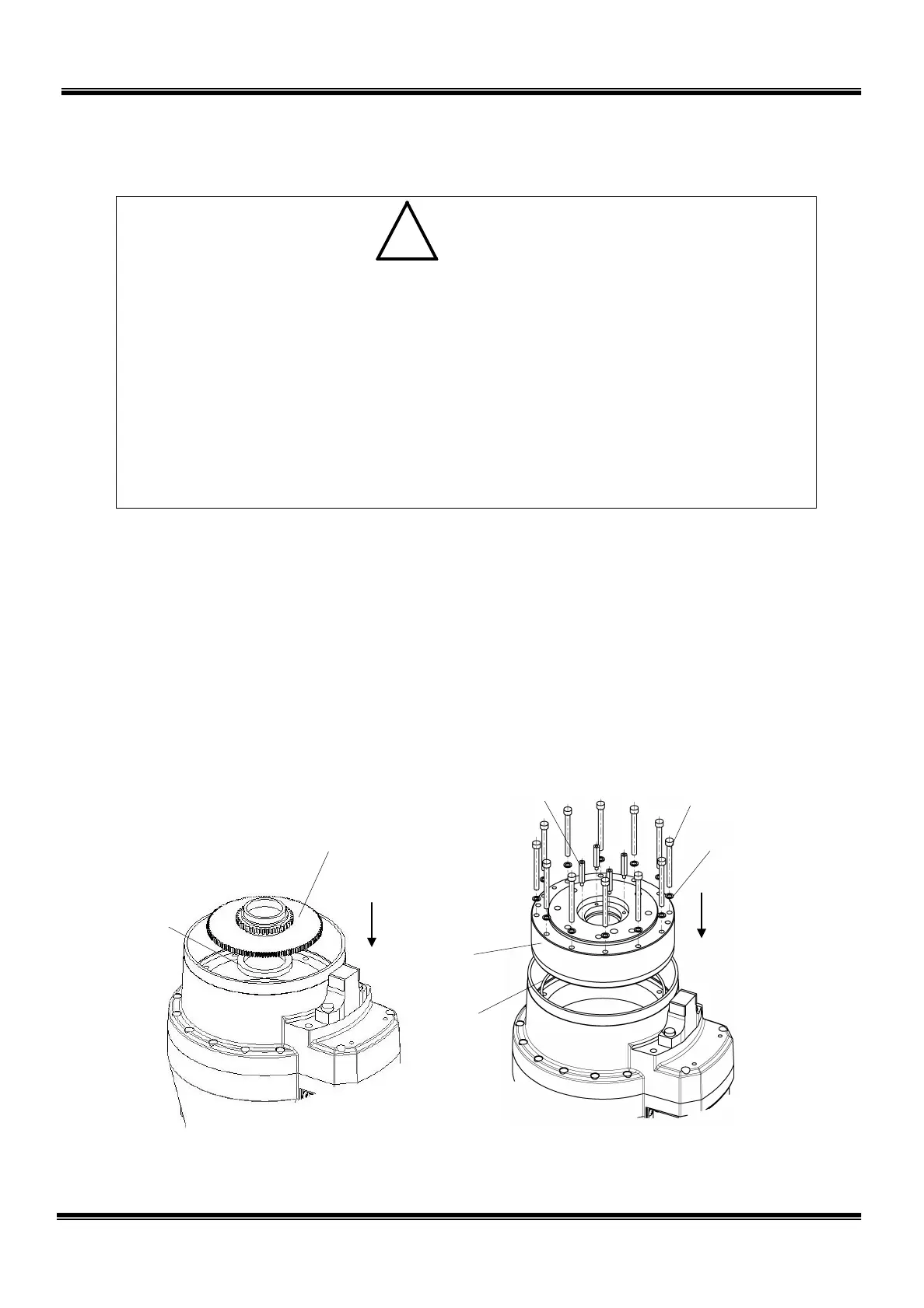

2) Mount the reduction gear with the twelve (12) bolts (M6 × 65). Be sure to apply

the Loctite adhesives to the threaded area of each bolt. Before mounting the

reduction gear, set the “O” ring in the “O” ring groove on the bottom of the

reduction gear. Attach the four (4) hexagonal struts. The “O” ring is attached

to the new reduction gear.

Center gear

The pinion is located

on the upper side.

M6×65

Recommended clamping

torque: 17 N

·m

STE 85306

– 71 –

Loading...

Loading...