124

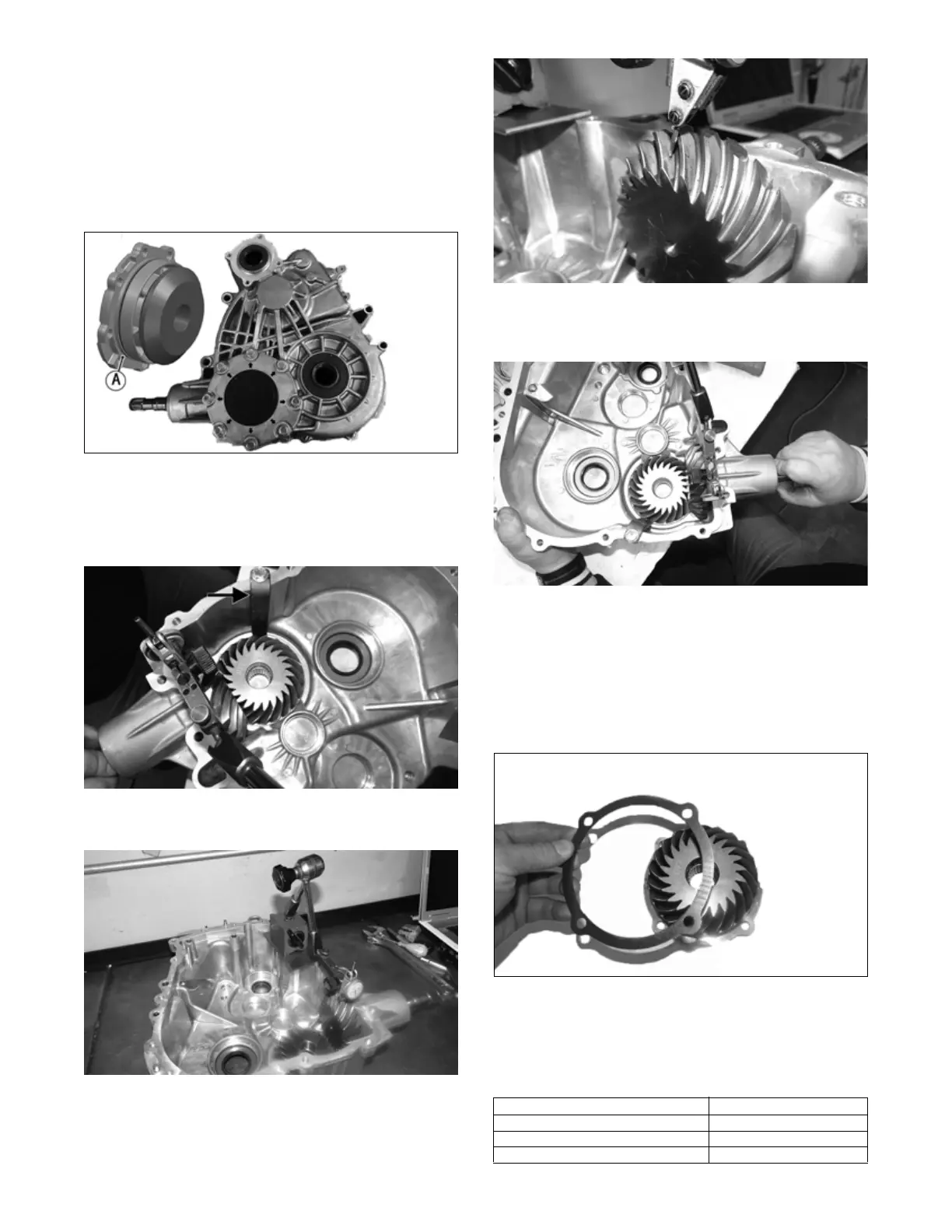

NOTE: To determine the appropriate shim, start

with the thickest shim and install the snap ring. If the

snap ring will not fit in the groove, remove the shim

and install the next size smaller shim. Continue until

the snap ring can be installed.

2. With the appropriate shim in place and a new O-ring

(A) coated with molybdenum grease, install the pin-

ion gear assembly into the case half and secure with

the eight screws. Tighten to 20 ft-lb (27.2 N-m).

NKL001B

NOTE: To determine the appropriate shim, proceed

to step 3.

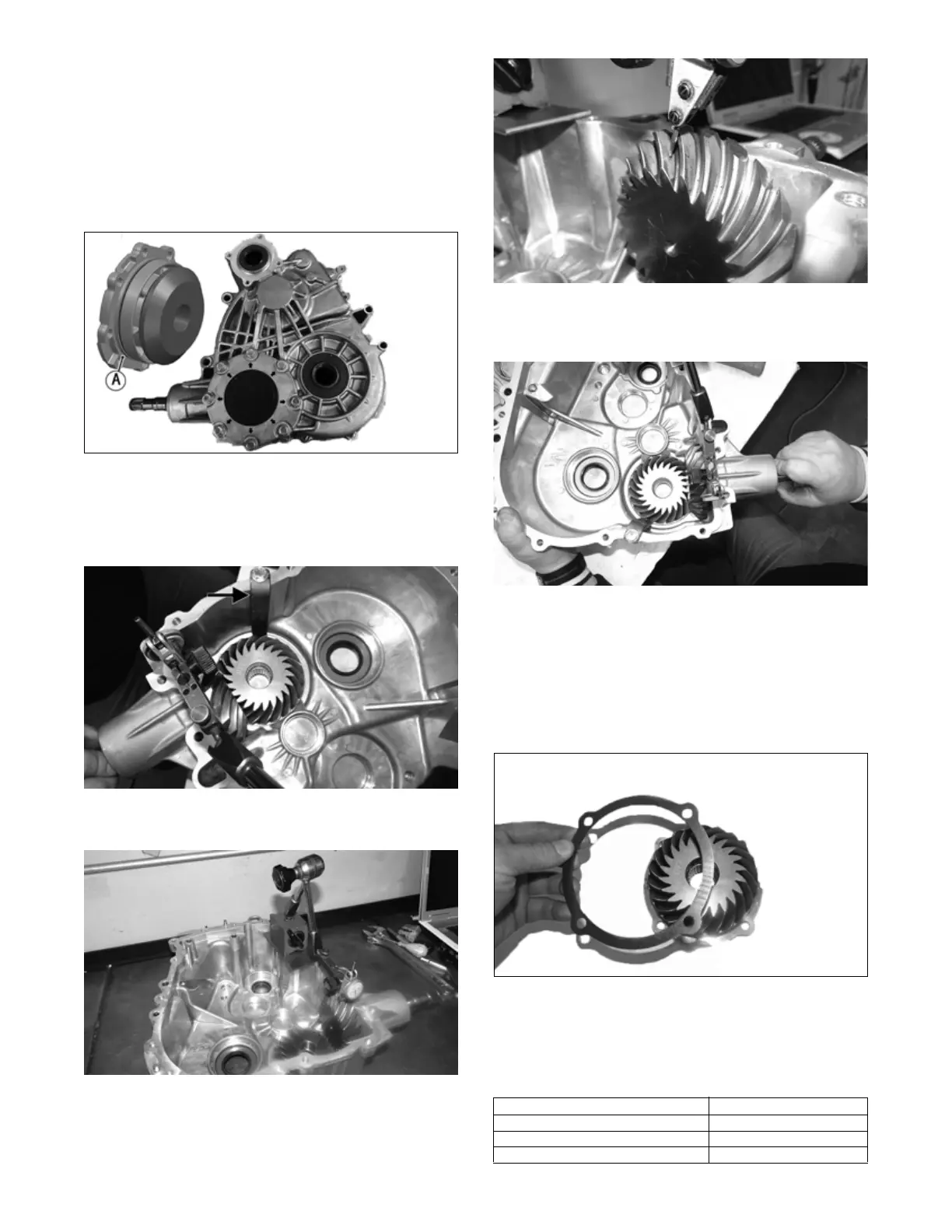

3. Using an appropriate tool, lock the pinion gear in

place.

TA124A

4. Mount a dial indicator so the tip is contacting a tooth

on the pinion shaft.

TA096

TA095

5. While pushing in on the front output shaft, and while

rocking the shaft back and forth and note the maxi-

mum backlash reading on the gauge.

TA125

6. Acceptable backlash range is 0.076-0.241 mm

(0.003-0.0095 in).

NOTE: If backlash measurement is within the

acceptable range, no correction is necessary.

7. If backlash measurement is less than specified,

remove the existing shim and install a new thicker

shim (from shim kit).

TA102

8. If backlash measurement is more than specified,

remove the existing shim and install a thinner shim.

NOTE: Continue to remove, measure, and install

until backlash measurement is within tolerance. Note

the following chart:

Backlash Measurement Shim Correction

Under 0.076 mm (0.003 in) Increase Shim Thickness

At 0.076-0.241 mm (0.003-0.0095 in) No Correction Required

Over 0.241 mm (0.0095 in) Decrease Shim Thickness

Loading...

Loading...