125

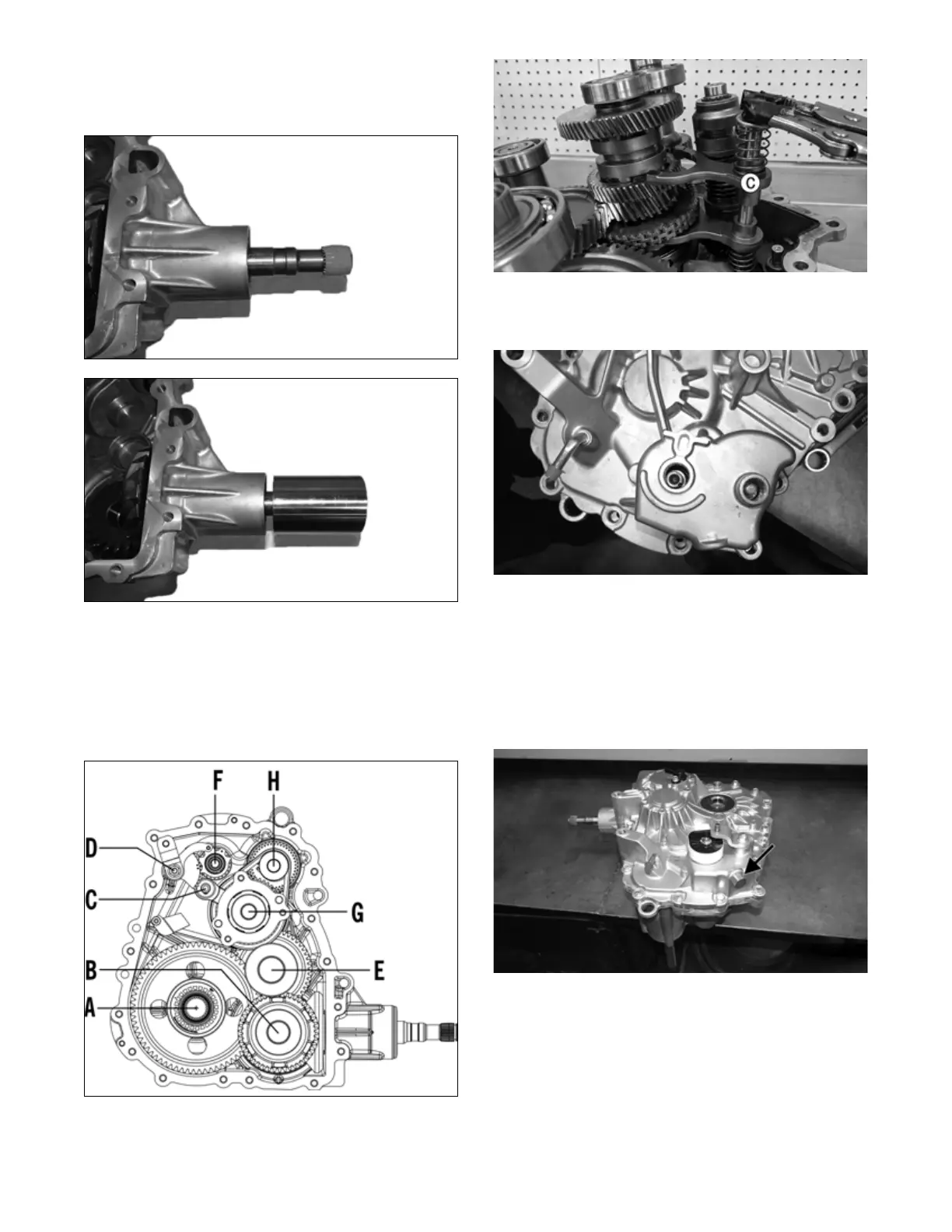

9. Tape the splined portion of the pinion shaft to protect

the seal; then using an appropriate seal installer,

install the front output seal so it seats fully past the

chamfer of the case.

TA129

TA130

ASSEMBLING HALVES

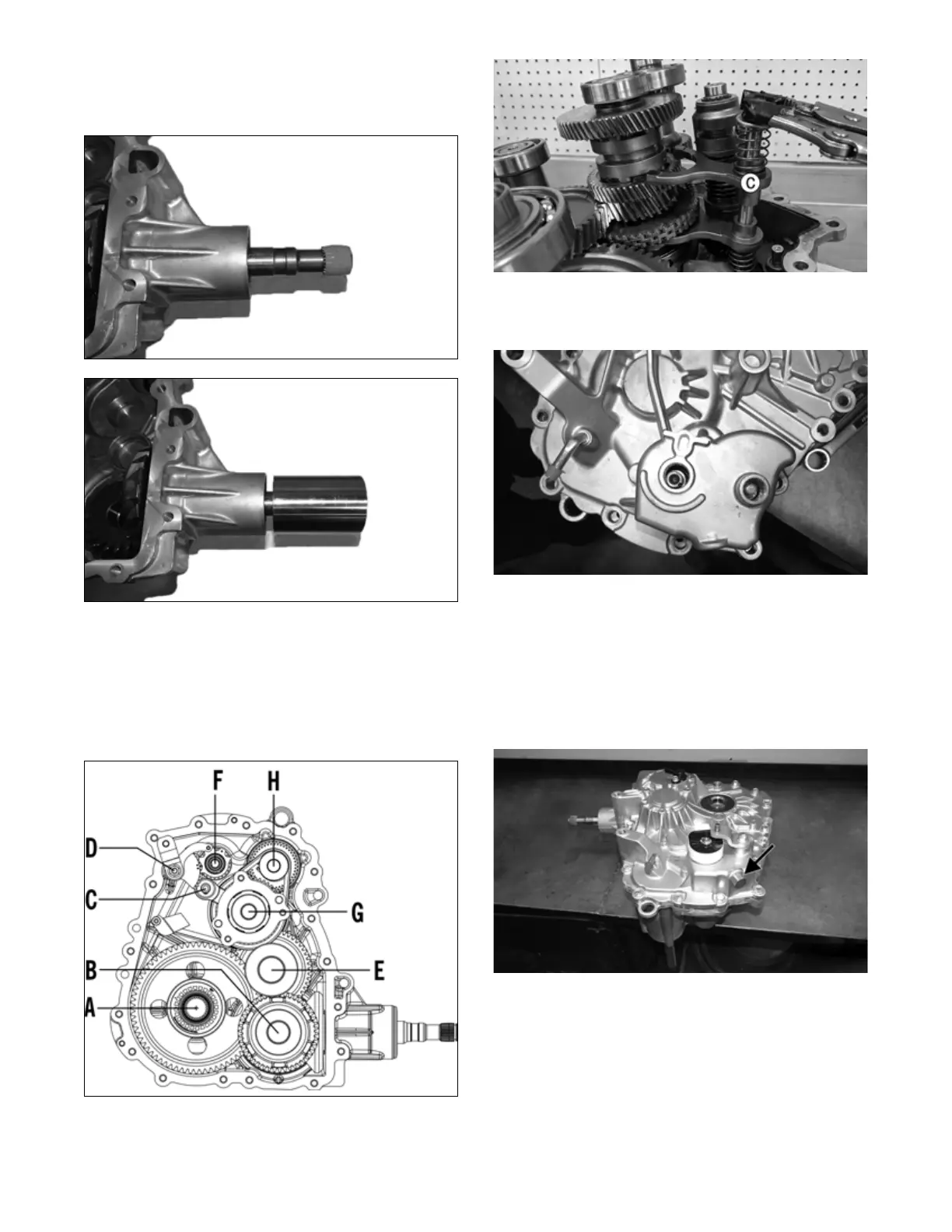

1. Reassemble components in proper location in lower

half, with the shift shaft rail (C) last. Position bottom

shift fork assembly shaft and pull up on shaft with

tool that is smooth or wrapped to prevent scaring of

shaft. Guide the forks in bottom and top grooves of

reverse shaft (G).

TA139

OHA128A

2. Apply a coat of Loctite 5699 to the case; then ensur-

ing the shift shaft (O-ring lightly coated with grease)

and shift rail are correctly seated, install the cover.

TA068

NOTE: It will be necessary to tap the cover onto the

case using a rubber mallet. Ensure the alignment pins

are properly oriented.

3. Secure the cover with the cap screws and tighten to

20 ft-lb (27.2 N-m).

4. Install the detent with spring and O-ring. Tighten to

20 ft-lb (27.2 N-m).

TA012A

5. Install gear position switch and speed sensor (see

Electrical System section).

6. Add approximately 1.2 quarts of Synthetic Transaxle

Fluid with EP to the transaxle. Verify fluid is level

with the bottom threads of the fill plug hole; then

install the fill plug and tighten to 16 ft-lb (21.8 N-m).

INSTALLING TRANSAXLE

1. Using new lock nuts, secure the bracket to the rear of

the transaxle. Tighten to 38 ft-lb (51.7 N-m).

Loading...

Loading...