54

LYC055

37. Oil camshaft bearing journals in cylinder head, and

place intake and exhaust camshafts in proper loca-

tions. Apply McLube® on cam lobes and axial bear-

ing shoulder of both camshafts. Oil camshaft

journals.

38. Rotate both camshafts into approximately the assem-

bly position.

NOTE: If sprocket is attached to camshaft, remove

sprocket from intake camshaft to make chain installa-

tion easier.

LYC056

39. Rotate crankshaft in the direction of engine operation

to the top dead center (TDC) position. Verify TDC

by removing the inspection cap from magneto cover.

Align magneto rotor so timing mark is centered in

inspection hole.

NOTE: If there is reason to suspect the engine is not

at TDC, perform a secondary check of TDC through

the spark plug hole.

NOTE: Remove magneto cover to determine the

cause of a misaligned timing mark.

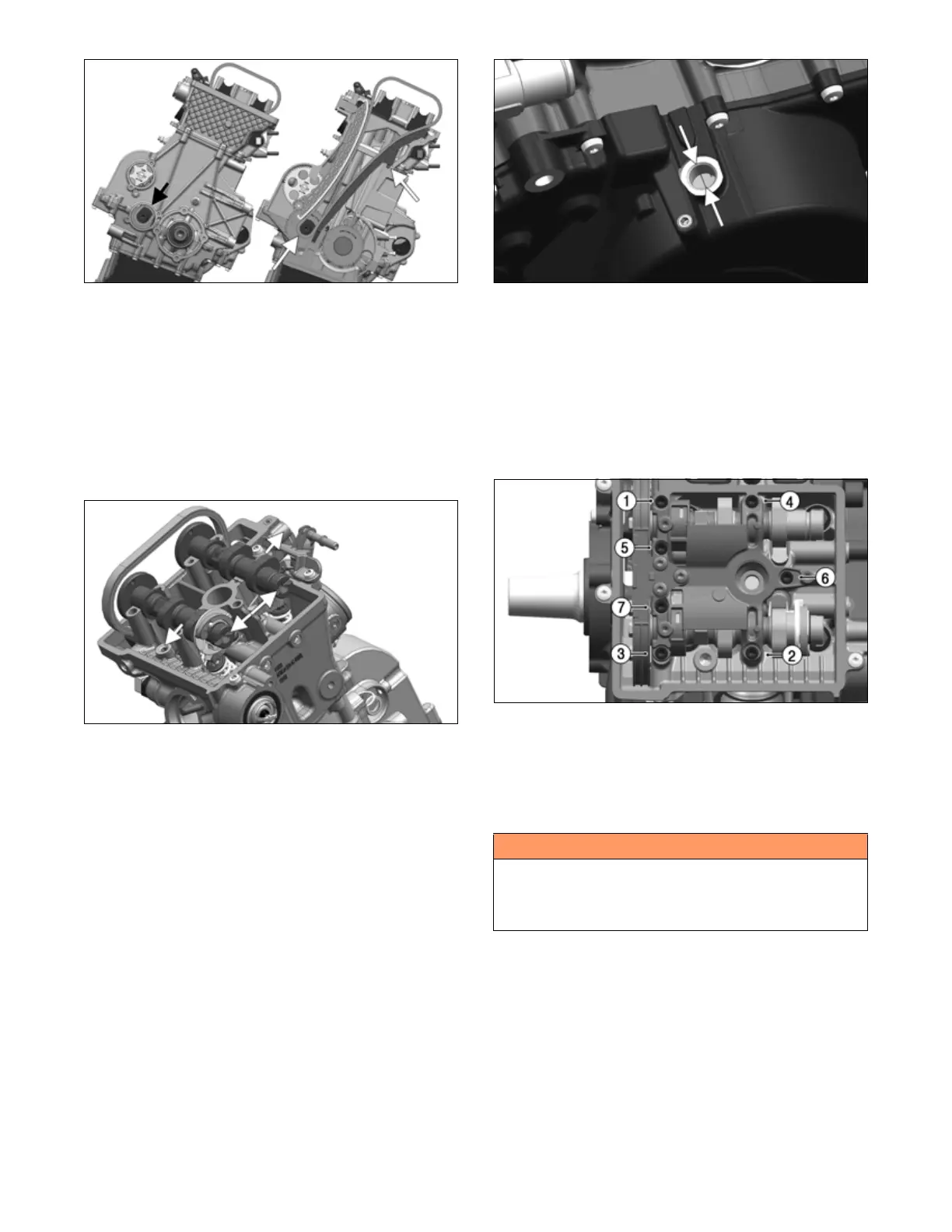

LYC034

40. Install O-ring in spark plug opening on cam bridge.

Position cam bridge carefully over camshafts. Secure

with seven bolts and carefully tighten by hand in pat-

tern illustrated. Tighten to 80 in-lb (9 N-m).

NOTE: Do not allow any misalignment between

cam bridge and cylinder head.

NOTE: Do not allow misalignment of rockers and

lifters while tightening the cam bridge.

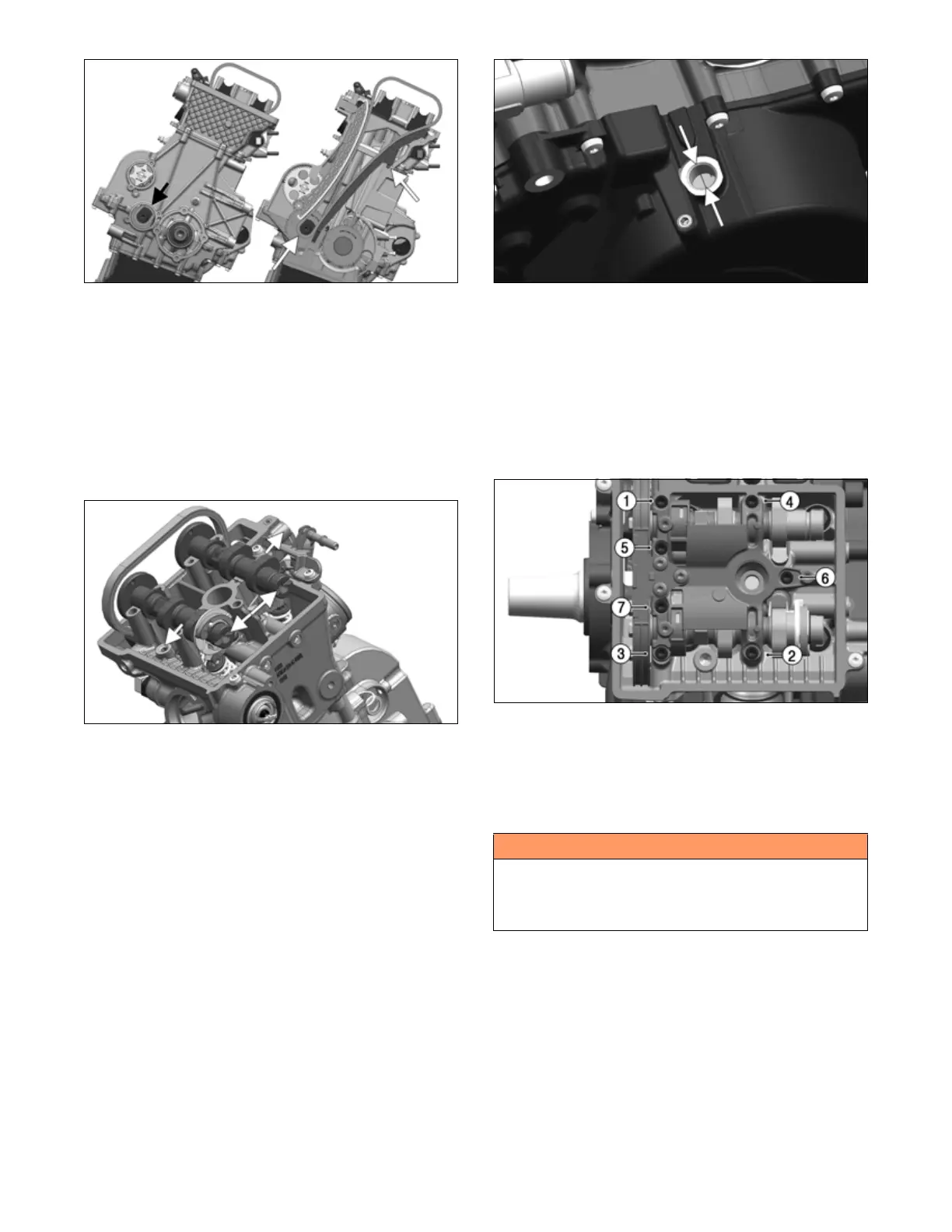

LYC039

41. Position camshafts with cam lobes facing away from

each other when slots are in line and insert a tool to

keep them in line.

NOTE: A 6 mm Allen wrench or bar placed between

both camshaft slots will ensure slots are in line.

! WARNING

Camshaft positions are optimized for this engine con-

figuration at the factory. Altering any parts or factory

settings may produce undesirable results and could

void the manufacturer's warranty.

Loading...

Loading...