Note:

Slanted or forced installation of the bush should be

avoided,and the bore surface of the bush should not

damaged.

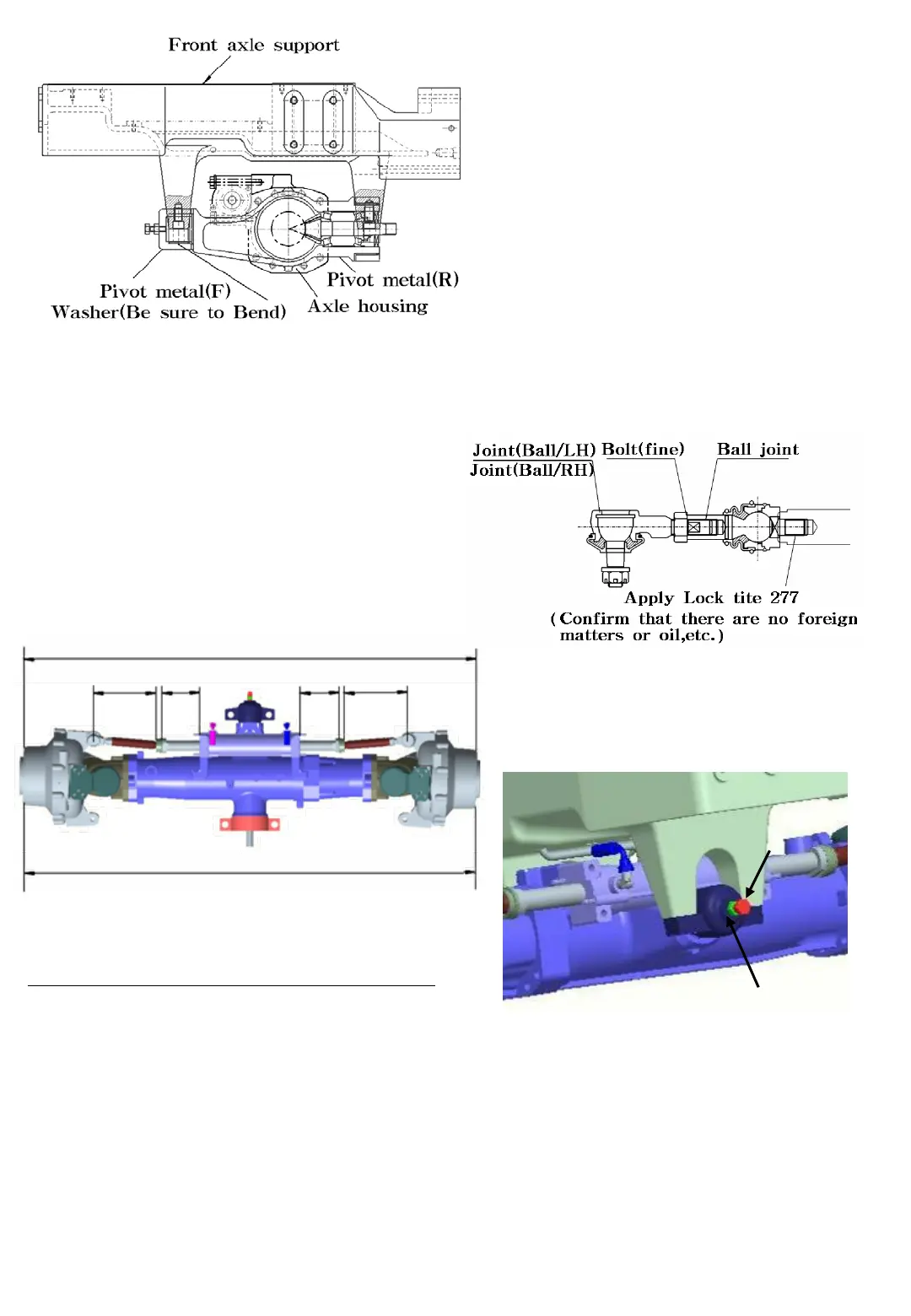

3) Pay particular attention to the installed direction

of thrust collar,that is, with the sharply-edged

face turned towards the bevel gear case.

4) When the thrust collar has been replaced or the

fore-and aft play of the front axle exceeds the

usable limit, correct play by screwing in the

adjust bolt on the top of the pivot metal (F)

6-5

Fig.6-9

Note:

After correcting the pivot metal play,

tighten the lock nut of the adjusting bolt

to a torque of 11.7~13.7KN-m

(12~14 kg-m)

5) The reassembled front axle should rock

smoothly while pivoting.

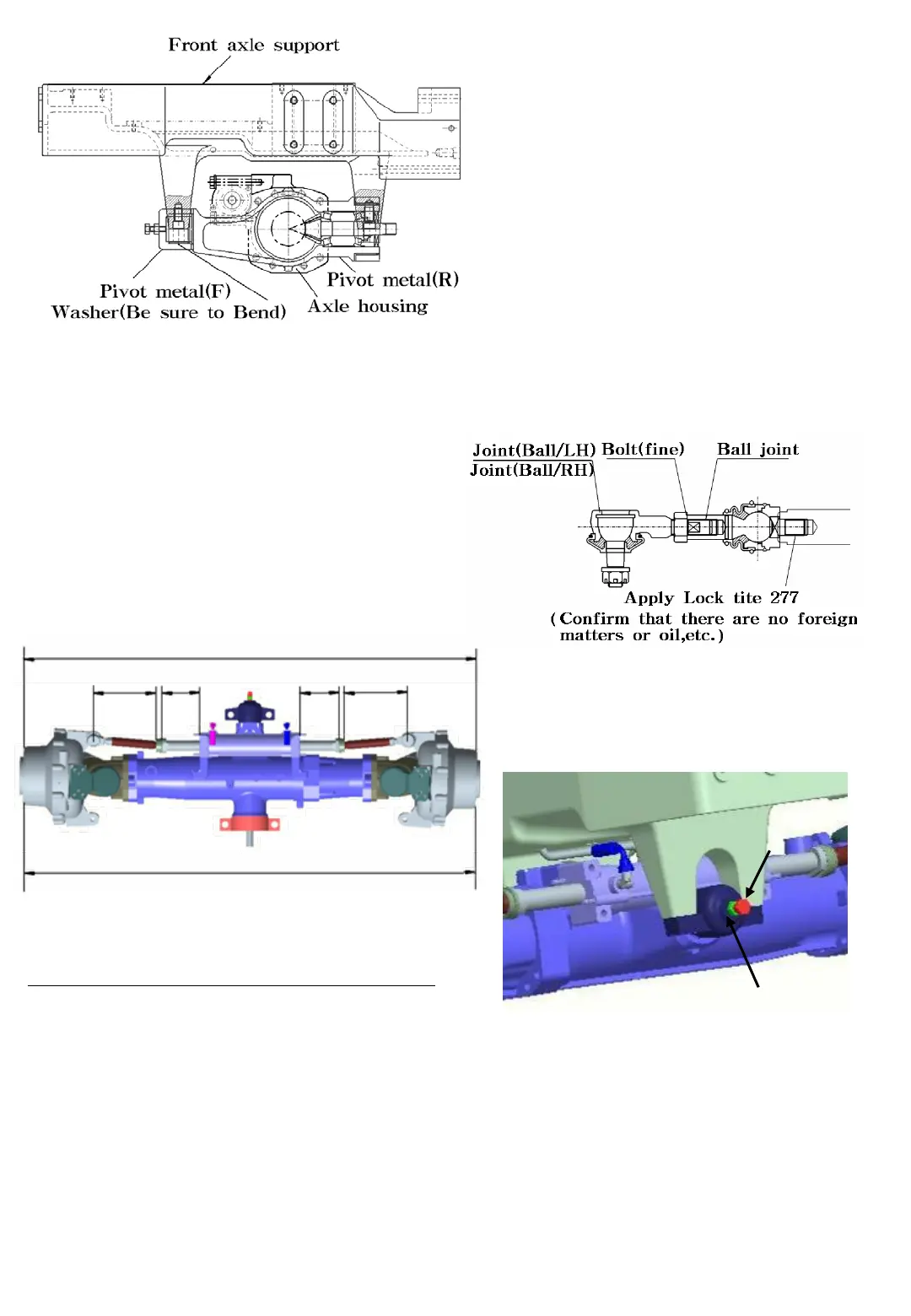

6) When the tie-rods are reinstalled,the

toe-in should be adjusted.At the same

time, the steering angles of the both

wheels should also be adjusted.

7) Be sure the dimension C and D is same

size and Adjust E and F as same

dimension. (B-A=0~5)

Tightening torque(M20x1.5p) : 24~26kg.m

GAP ADJUSTMENT ON THE FRONT AXLE

Lift the front with a hydraulic jack to get the

wheels of the ground.

Then loosen the nut and tighten the bolt fully

and turn the bolt ½ to loosen again in order to

roll the center pivot metal freely and tighten

the nut again While the wheels arte still off the

ground, move the axle on the center pivot as a

final check that the gap is set correctly on the top

of the pivot metal

Fig.6-7

Bolt

Nut

A

B

E

FD

A

C

Top View

Forward

Fig.6-8

Loading...

Loading...