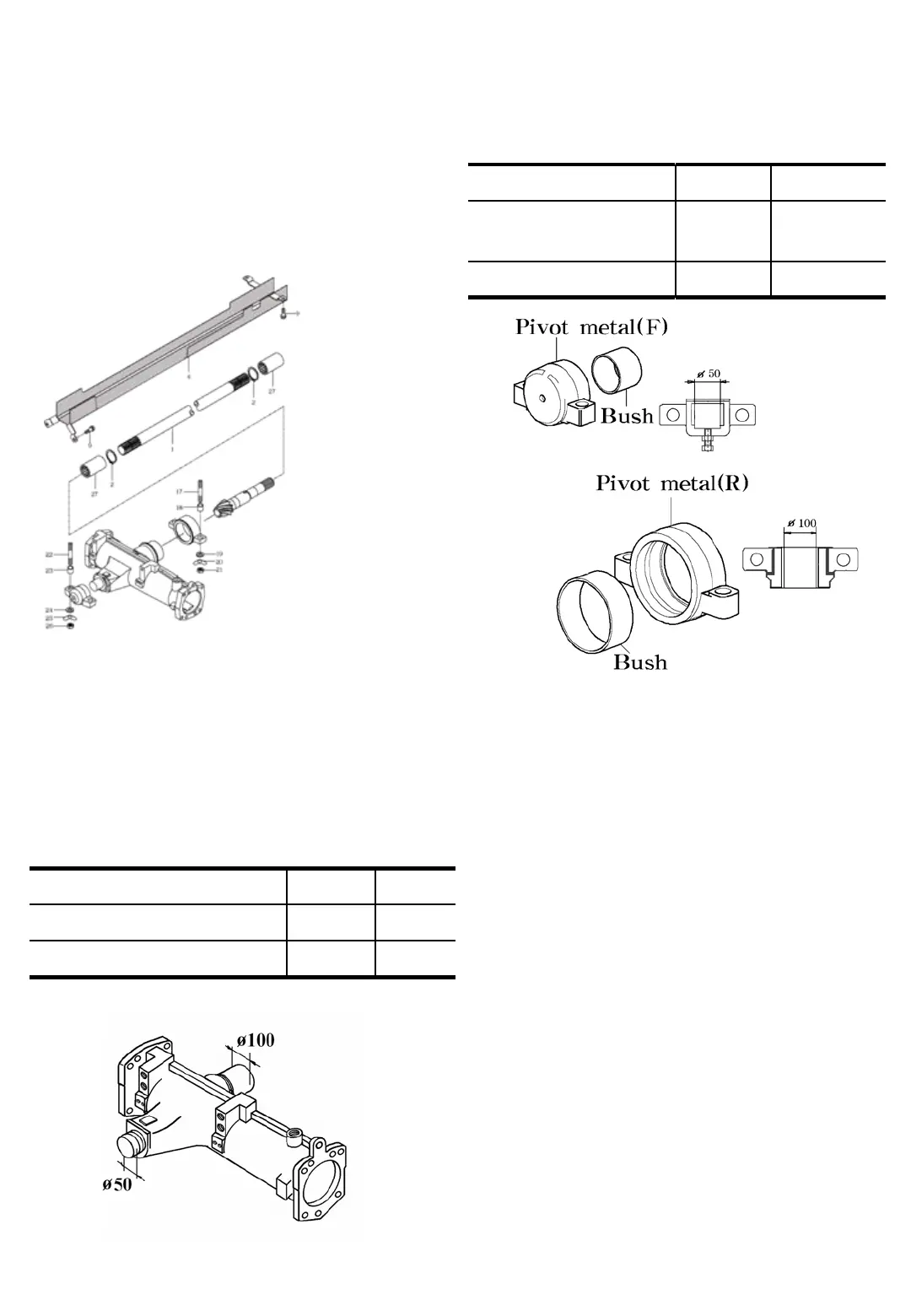

1.1.DISASSEMBLY

1) Dismount the front wheel drive shaft,

referring to the pertinent paragraph in chapter 2.

2) Remove the right and left tie rods.

3) Suspend the front axle bracket with a chain.

4) Remove the front metal clamping bolts.The

front axle can then be separated from the axle

bracket.

5) Remove the front and rear pivot metals.

1.2.INSPECTION

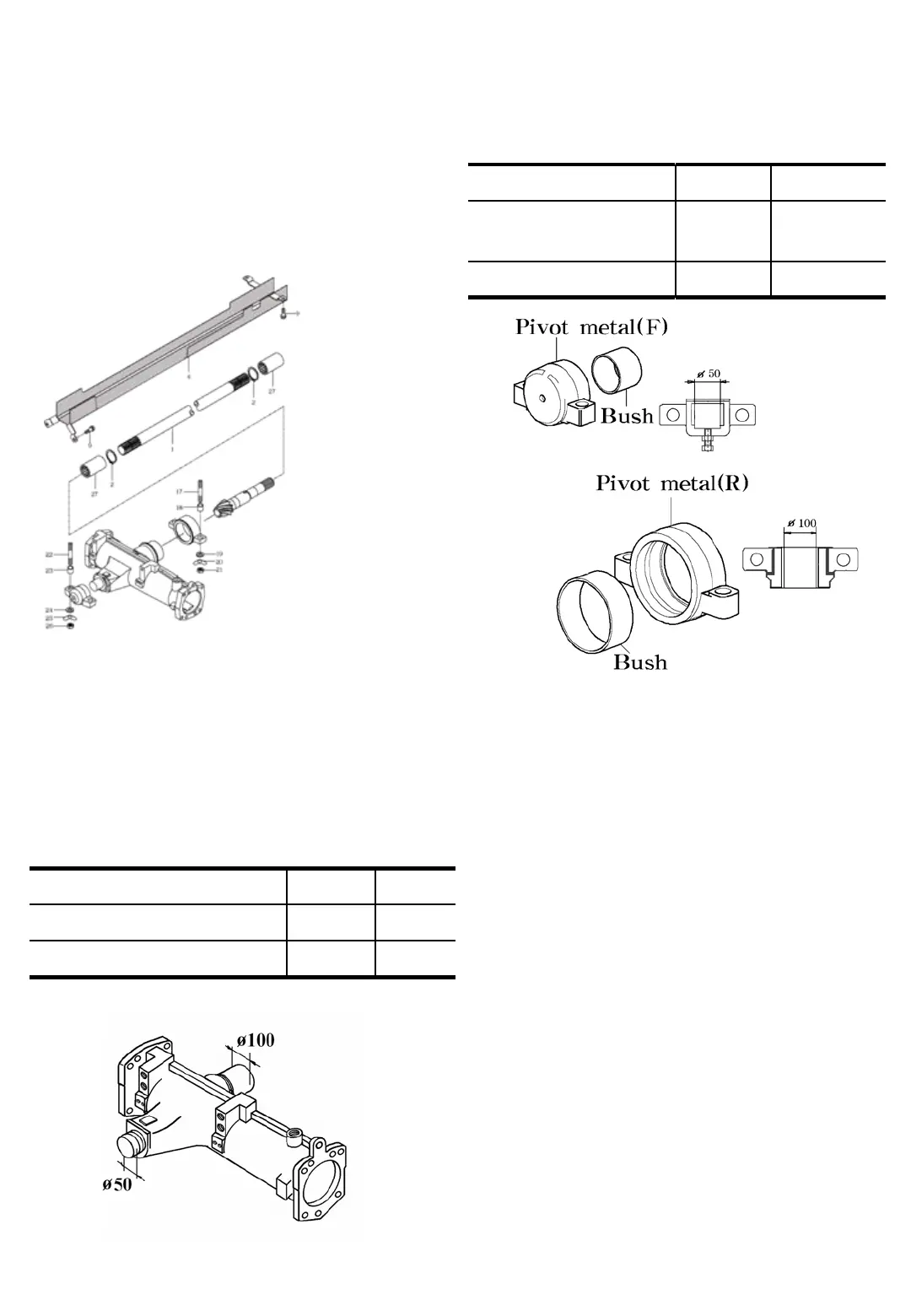

1) FRONT AXLE SHAFT DIAMETER

Measure the diameter at a roll bush contact point

with a micro-meter or vernier calipers. If the

measured value is less than usable limit, replace

the housing front axle or bush in Metal pivot (F) or

Metal pivot (R) .

Front rear

Standard value as assembled Ø50 Ø100

Usable limit Ø49.9 Ø99.9

2) FRONT AXLE BUSH BORE DIAMETER

Measure the bore diameter of the roll bush in the

pivot metal (F). If the measured value exceeds

the usable limit, replace the bush.

Front rear

Standard value as

assembled

Ø50 Ø100

Usable limit Ø50.35 Ø100.35

3) Worn or damaged oil seals,O-rings, bearings,

etc. should be replaced.

1.3 REASSEMBLY

Reassemble the parts in reverse order of

disassembly, following these instructions.

1) Lips of the oil seals,bush contact surfaces,

and O-rings should be coated with grease

in advance.

2) When installing the roll bushes, abide by

the following precautions.

-Use an installer and press in the bush on a press.

-The bore surface should be coated with grease

in advance.

-The shim of the roll bush should reach position

as shown Fig.6-7. In other words the seam

should be in a position which is free from any

load.

Fig.6-6

6-4

Fig.6-4

Fig.6-5

Loading...

Loading...