4-5

2.CLUTCH SHAFT AND RELATED PARTS.

(1) disassembly

1) Remove the tension spring and extract the

sleeve

2) Remove the wire which is retaining the

taper pin.

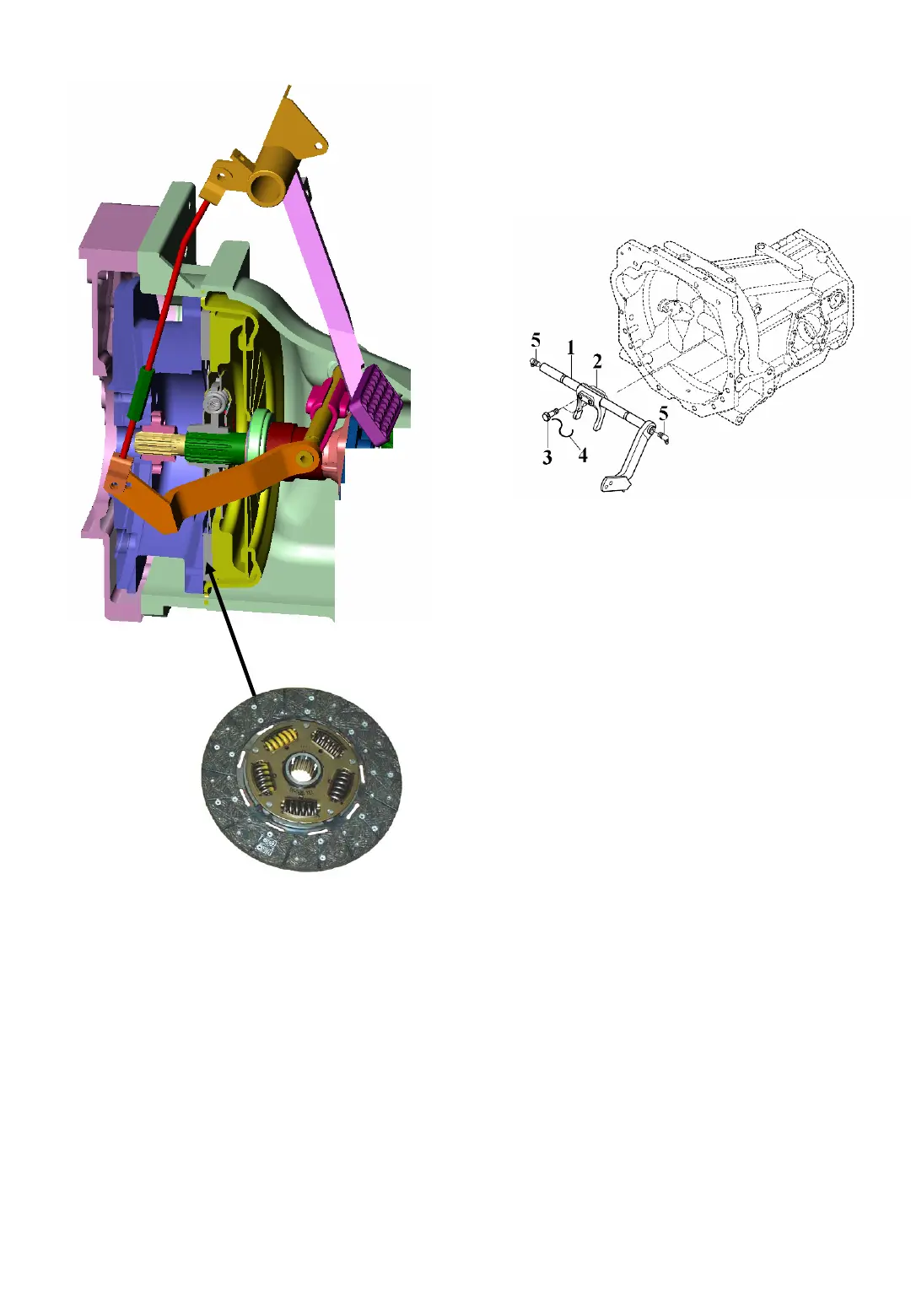

①Clutch shaft comp ②Release fork

③Taper pin ④Wire ⑤Grease fitting

Fig.4-8 Main clutch and related parts

3)Remove the grease fittings from the clutch

shaft ends.

4)Turn the release fork upward and pull out

the taper pin.Then draw the clutch shaft.

(2) Inspection

1) Inspection of release bearing

The release bearing is of the grease-sealed

type,but when the grease in the bearing

reaches a low level or the bearing does

not turn smoothly due to damage or seizure,

replace the bearing.

Note:

The release bearing should not be washed.

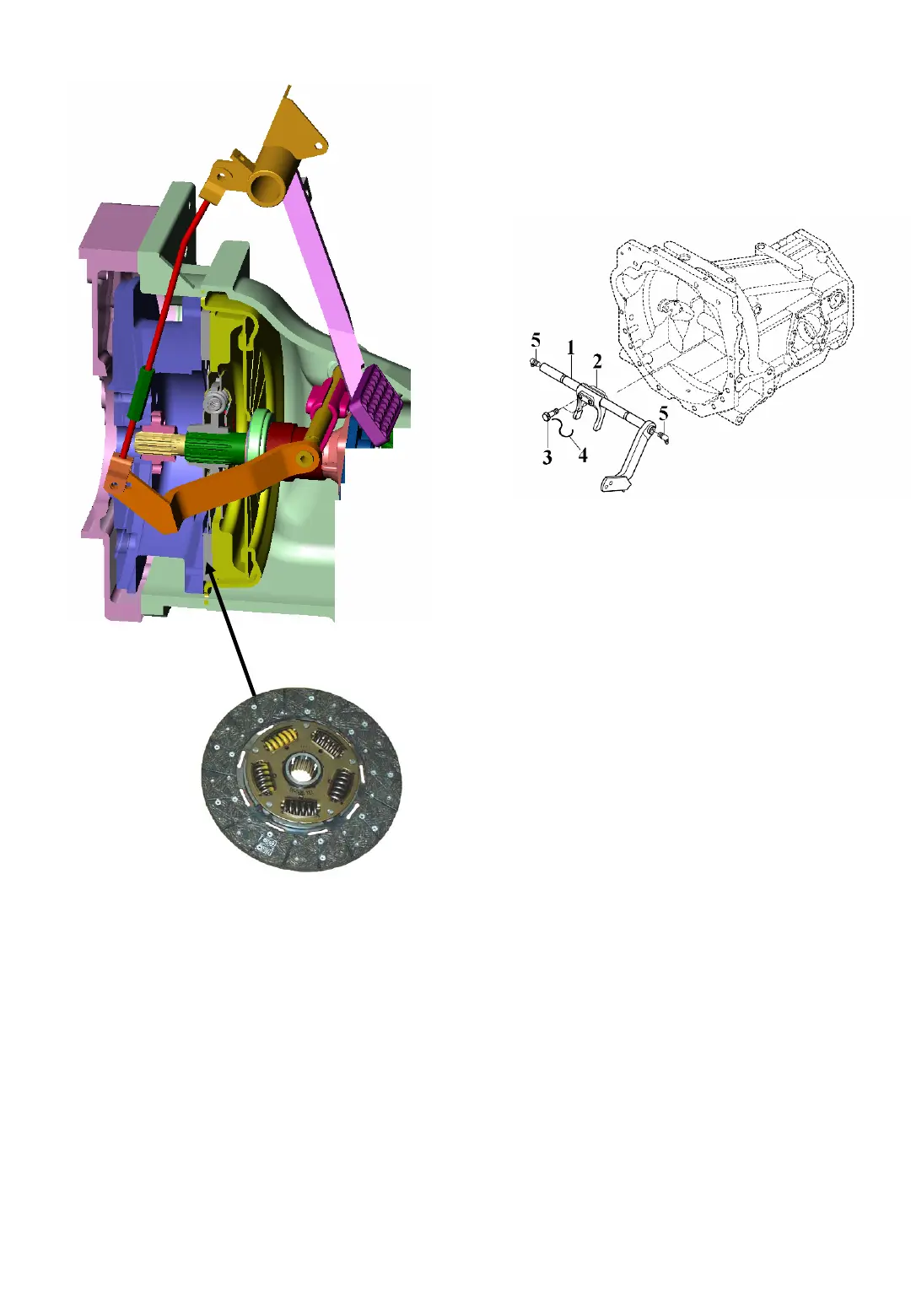

Fig.4-7

Loading...

Loading...