(3) O-rings

1) O-rings should be coated with grease

before installing.

2) Installed O-rings should have no slack or

twist.

3) Installed O-rings should maintain proper

air tightness.

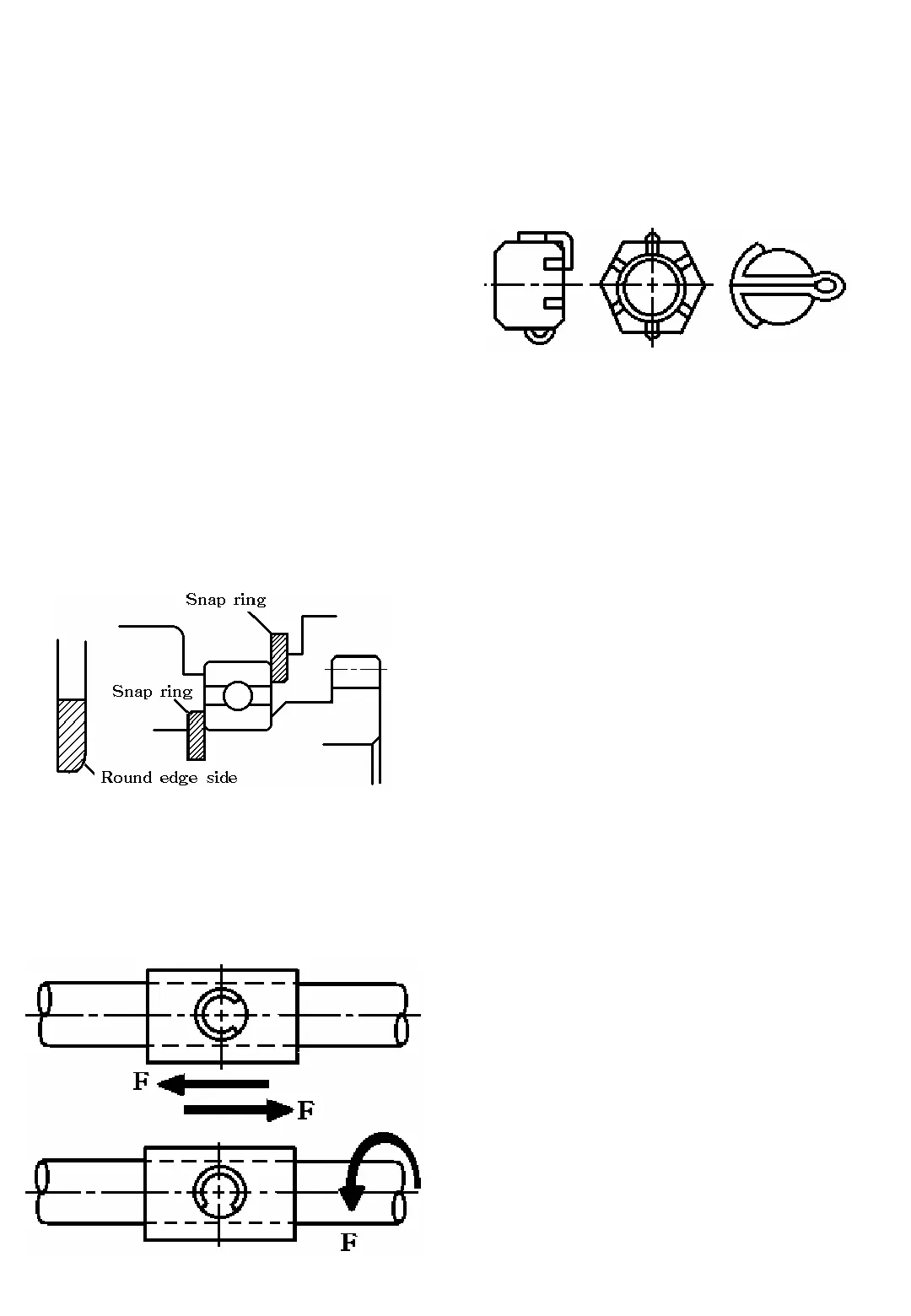

(4) Snap rings

1) Snap ring installers should be designed so

as not to permanently deform the snap

rings.

2) Installed snap rings should be seated

securely in the groove.

3) Be careful not to overload the snap ring

to the extent that it is permanently

deformed.

4) How to install the snap ring:

When installing a snap ring,install it as

shown in the figure with its round edge

side turned toward the part to be

retained.This round edge is formed when

the snap ring is pressed out.

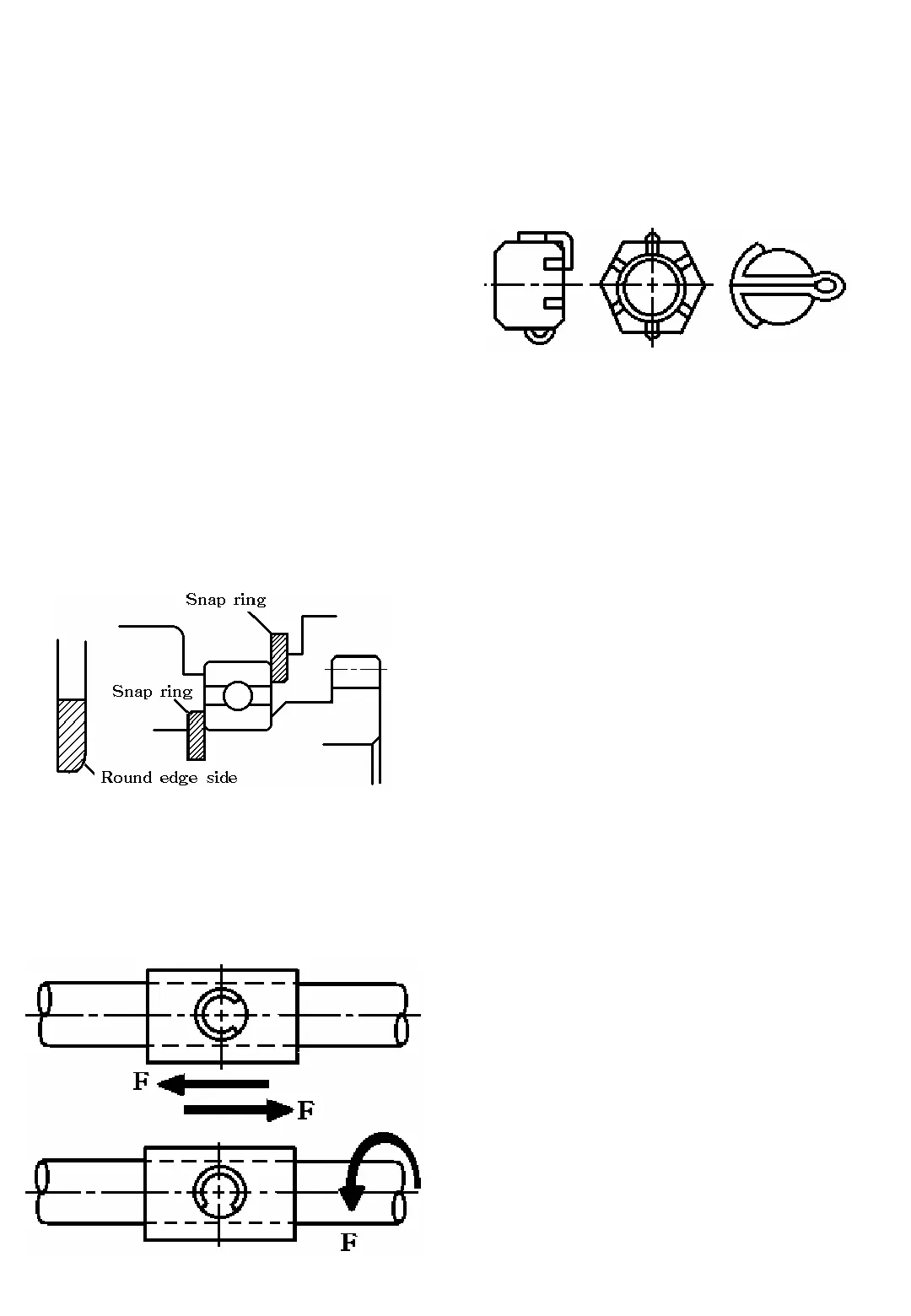

(5) Spring(roll) pins

1) Spring pins should be driven in properly as

tightly.

2) Spring pins should be installed so that their

seams should face the direction from which the

load is applied.

3) The roll pins installed in the transmission or

other parts where much force is applied

should be retained with the wire.

Fig.2-1

(6) Cotter pins

When installed, cotter pins should be bent

securely at the ends as shown in the figure

Fig.2-3

2-2

Fig.2-2

(7) Bolts and nuts

1)Special bolts are installed at several locations,

so be sure not to interchange them other bolts.

2) Bolts and nuts should be tightened to their

specified torque wrench.

3) When locking the bolts or nuts with wire or

a lock washer, Be sure to wind the wire paying

sufficient attention to its winding direction and

bend the lock washer for secure looking.

4) When locking bolts and nuts with an adhesive,

apply the adhesive on the thread and tighten

securely.

5) Apply an adhesive(THREE BOND TB1104)

to parts through which there is any possibility

of oil leaks,such as stud bolts and tapped-

through parts.

6) Each lock nut must be tightened securely.

7) When tightening bolts and nuts, refer to the

tightening torque table.

(8) After installation, each grease fitting

should be filled with grease.

1) When installing grease fittings of type B and

C, be sure to turn the fitting tips in a direction

that will provide easy access for a grease gun.

(9) Other precautions

1) Be sure not to damage any finished surfaces

or parts.

2) Always refrain from forcing installation.

3) Each lever knob should be installed coated

with an adhesive

(SUPER THREE CEMENT TB1702)

Loading...

Loading...