5-7

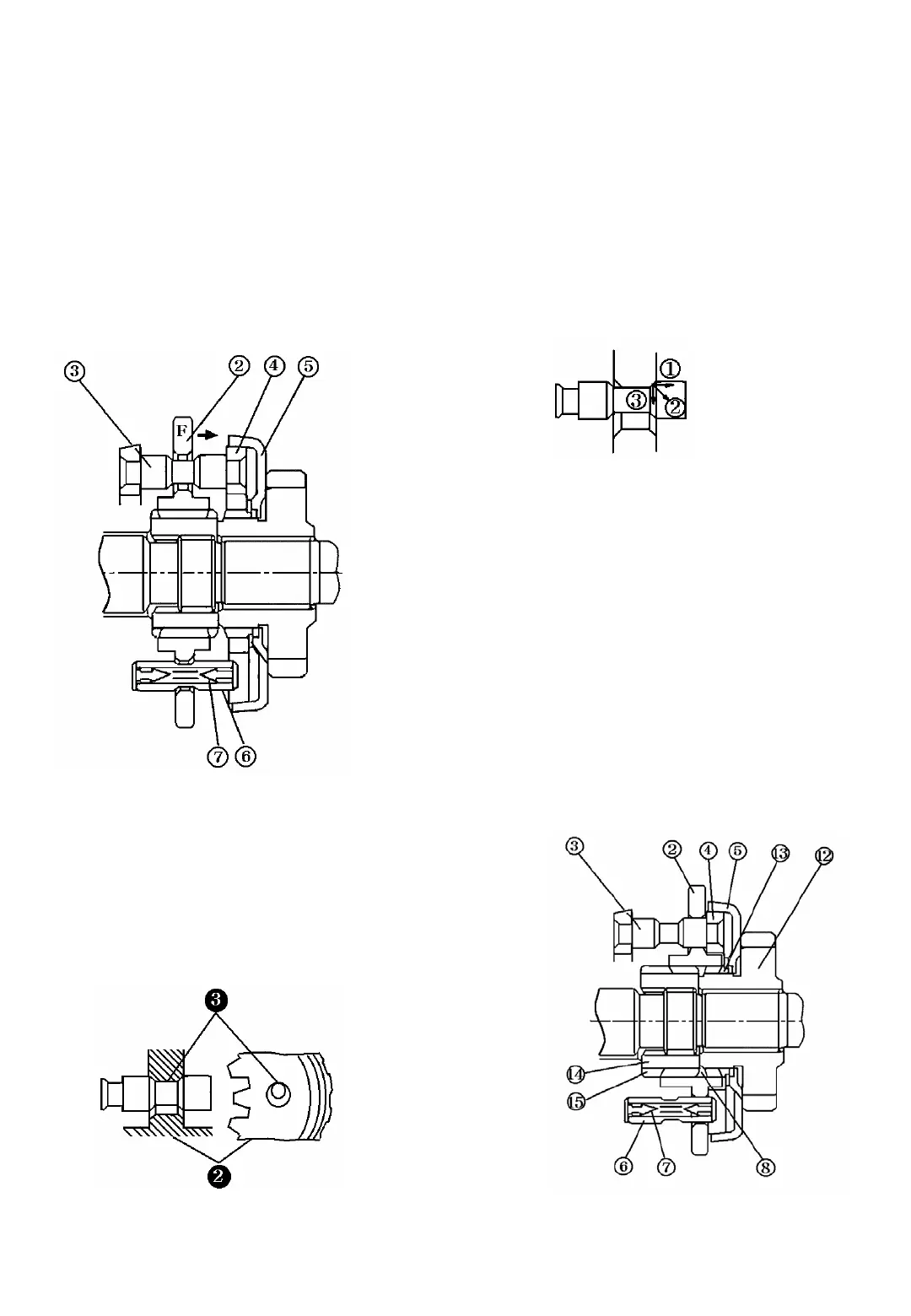

Fig. 5-16 1st stage

2nd stage:

At the moment when both the friction surfaces come

into contact,the ring turns by as much as the surplus

space in hub(2) for block pin(3)as shown in Fig.5-5

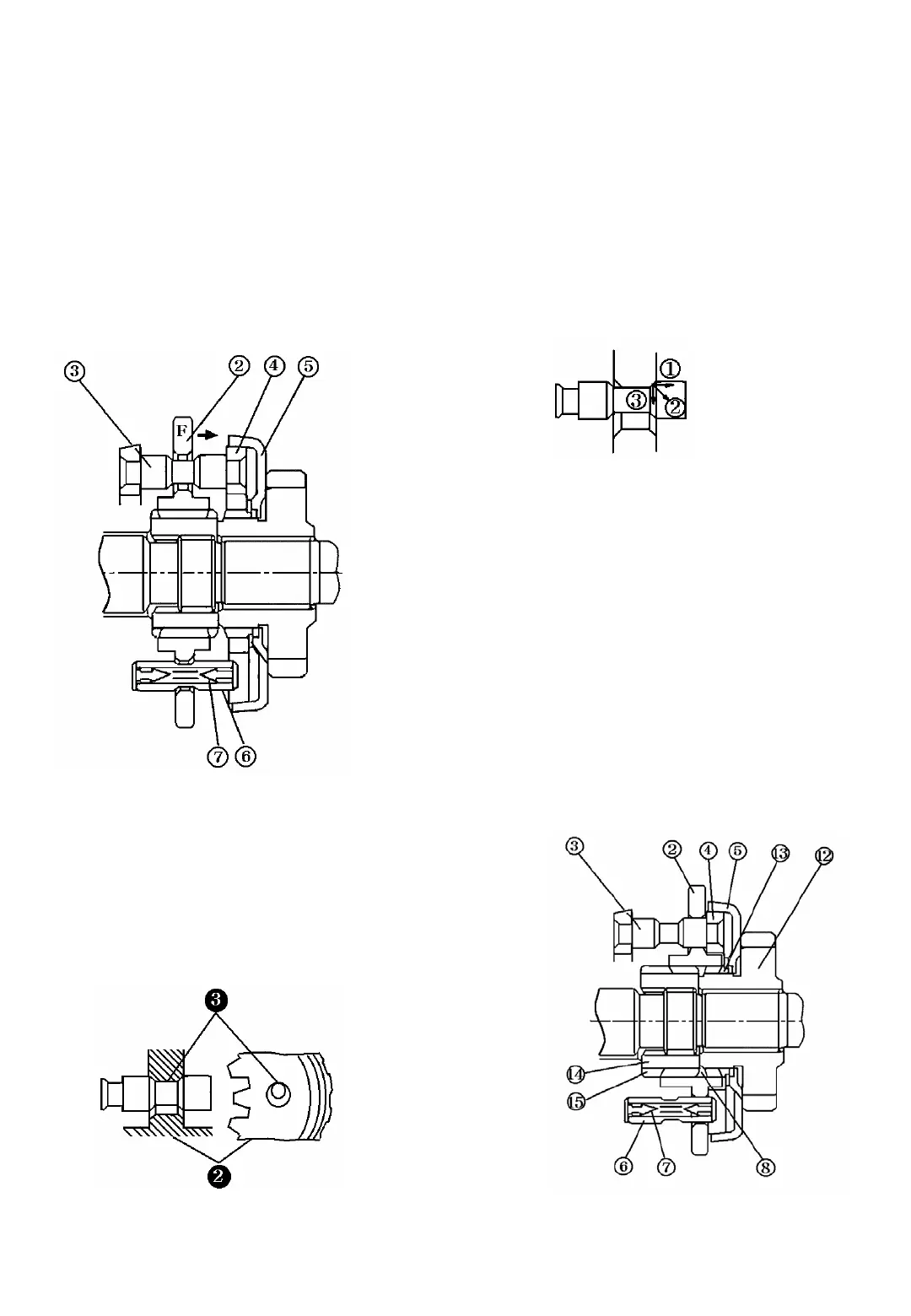

Fig.5-17 Block-pin

3rd stage:

When hub(2)is pushed further,the tapered surface

in the hole of the hub and the tapered surface on

the block pin are pressed tightly against each

other,this pushes synchro-ring(4) against

synchro-cup(5).Consequently,as shown Fig.5-

6,the synchro-ring and the synchro-cup are

pressed more tightly against each other by the

resultant turning force of the rear wheel and the

thrust of the shifter.Ultimately,the revolving

speeds of the synchro-ring and the synchro-cup

become the same.

(1)Thrust

(2)Resultant force

(3)Turning force

Fig. 5-18 Synchro-ring and cup

4th stage :

When synchro-ring(4) and synchro-cup(5)

reach the same speed,the friction force

disappears.Then the resistance between

hub(2)and block pin(3) also disappears to allow

the hub to clear the groove on the block pin and

to sit on the large diameter area of the pin. At

the same time,thrust piece(6) which has a

tapered shape and hub(2) advance smoothly on

the pin to complete the meshing between

spline(8) of the hub and spline(13) of the gear.

Fig. 5-19 Complete Synchro-ring and cup

1st stage:

When force(F) is applied to shifter(1)

through the gear shift lever,hub(2) is pushed

in the direction of the arrow.Following

movement of the hub,other parts such as

block pin(3), synchro-ring(4),and thrust

piece(6) also move in the same direction by

means of spring(7), without allowing the

hub to clear the groove in thrust piece(6)

until such time as the friction surface of

synchro-ring (4)comes into contact with the

friction surface of synchro-cup (5).

Loading...

Loading...