GPSModules-SystemIntegrationManual(SIM)(incl.ReferenceDesign) Design-In

GPS.G4-MS4-05007-A1

Page 53

your position is our focus

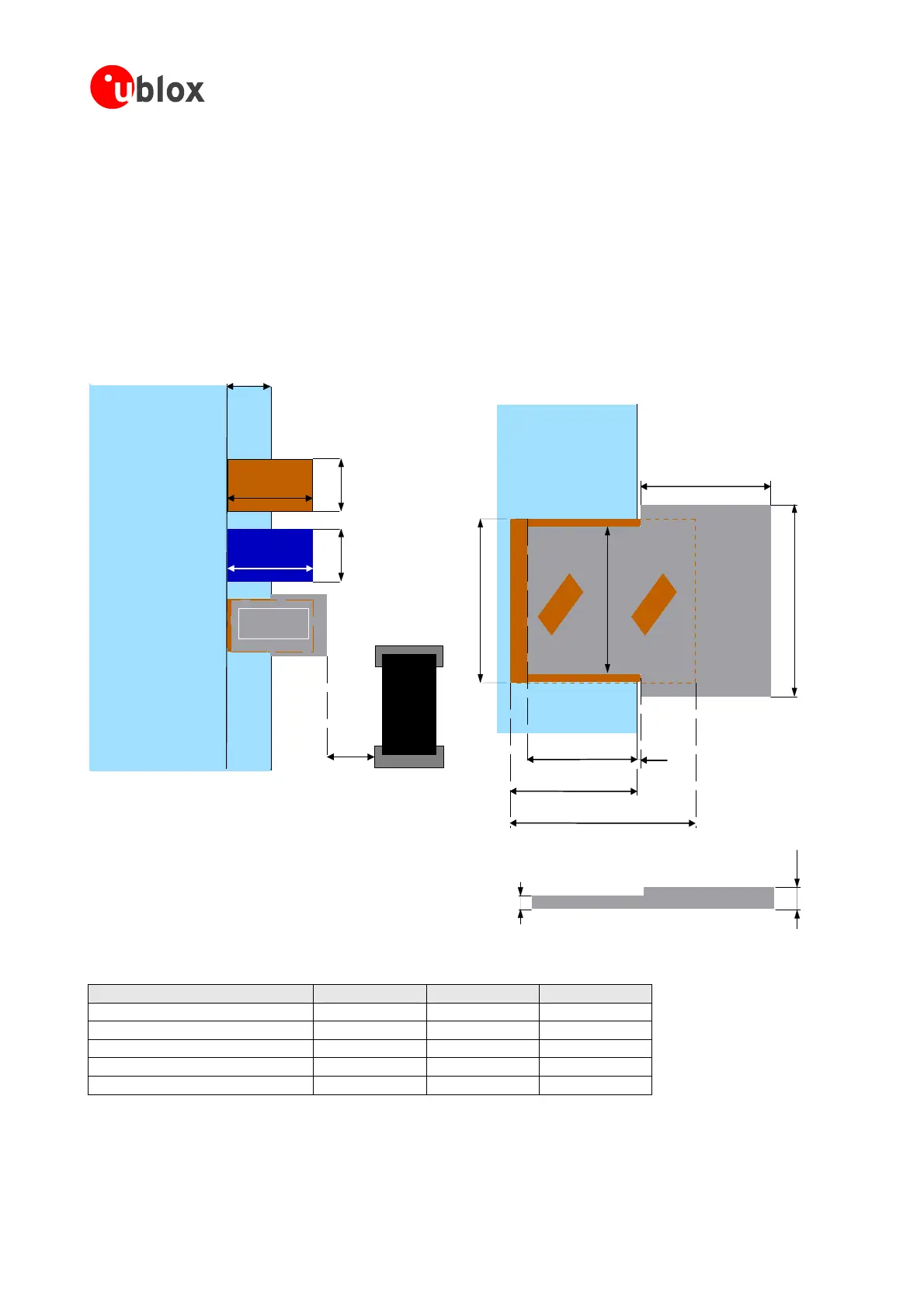

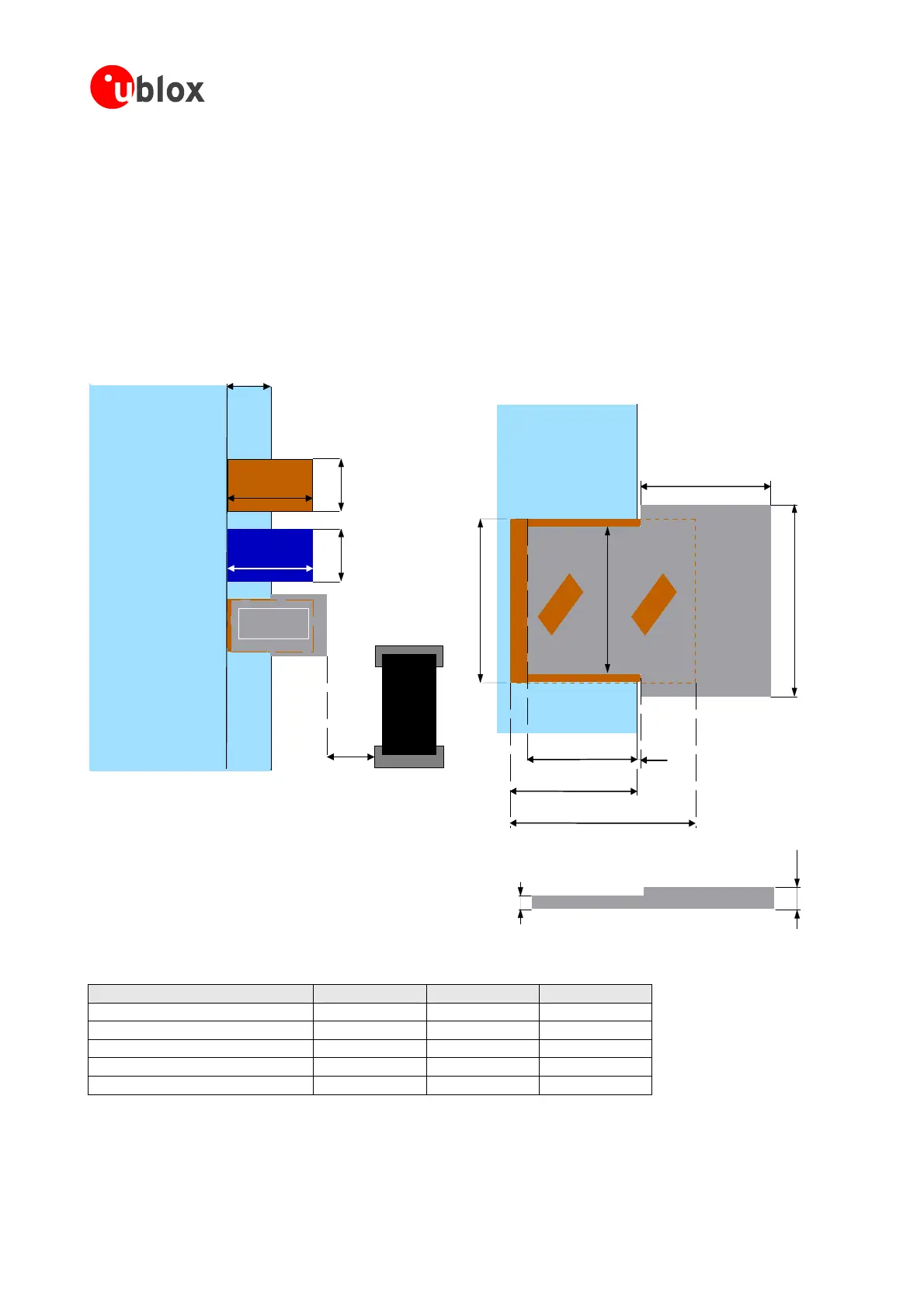

3.6.2 Paste Mask

Module

0.8mm

[32m il]

a

a

Cu mask

Solder mask

Paste mask

minimal

distanceto

next

componen t

See

Enlargement

b

0.8mm

[32m il]

d

a

Solder Paste

e

c

Cu Pad

0.8mm[3 2 m il]

C

u

Ma

s

k

Module

0.65mm

[

2 6 m il]

Cu Mask

Cu

Ma

s

k

b

0.1mm

[4mil]

0.2mm

[7 8 m il]

0.15mm

[5 9 m il]

SolderPaste:crosssection

ENLARGEMENT

Figure41andTable8demonstratetherecommendedpositioningofCu,SolderandPasteMasks,aswellasthe

suggested distances. Note that these are recommendations only and not specifications. The exact geometry,

distancesandsolderpastevolumesmustbeadaptedtothespecificproductionprocesses(e.g.solderingetc.)of

e mask under the

moduleandtoincreasetheamountofpastemaskoutsidethemodulebyusingastepstencilandexceedingthe

pastemask beyond theCu Mask asshown in

Figure41.If astepstencil isnotused itis stillrecommended to

employthesamevolumeofsolderpasteoutsidethemoduletoattainthedesiredlevelofwetting.Thiswillhave

tobedonebymodifyingtheshapeofthepastemaskoutsidethemodule.

Figure 41: Solder and paste mask with enlargement showing positioning and cross section of underlying solder paste

the

customer.

To improve the wetting of the half vias it is recommended to reduce the amount of past

Dimension TIM-4x LEA-4x

NEO-4S

a 1.8mm[70mil] 1.8mm[70mil] 1.7mm[66mil]

b 1.0mm[39mil] 1.0mm[39mil] 0.9mm[35mil]

c 0.65mm[26mil] 0.65mm[26mil] 0.65mm[26mil]

d 0.9mm[35mil] 0.8mm[32mil] 0.8mm[32mil]

e 1.3mm[51mil] 1.5mm[59mil] 1.5mm[59mil]

Table 8: Paste Mask Dimensions for TIM-4x, LEA-4x and NEO-4S

Note The exact geometry, distances, stencil thicknesses, step heights and solder paste volumes must be

adaptedtothespecificproductionprocesses(e.g.solderingetc.)ofthecustomer.

Loading...

Loading...