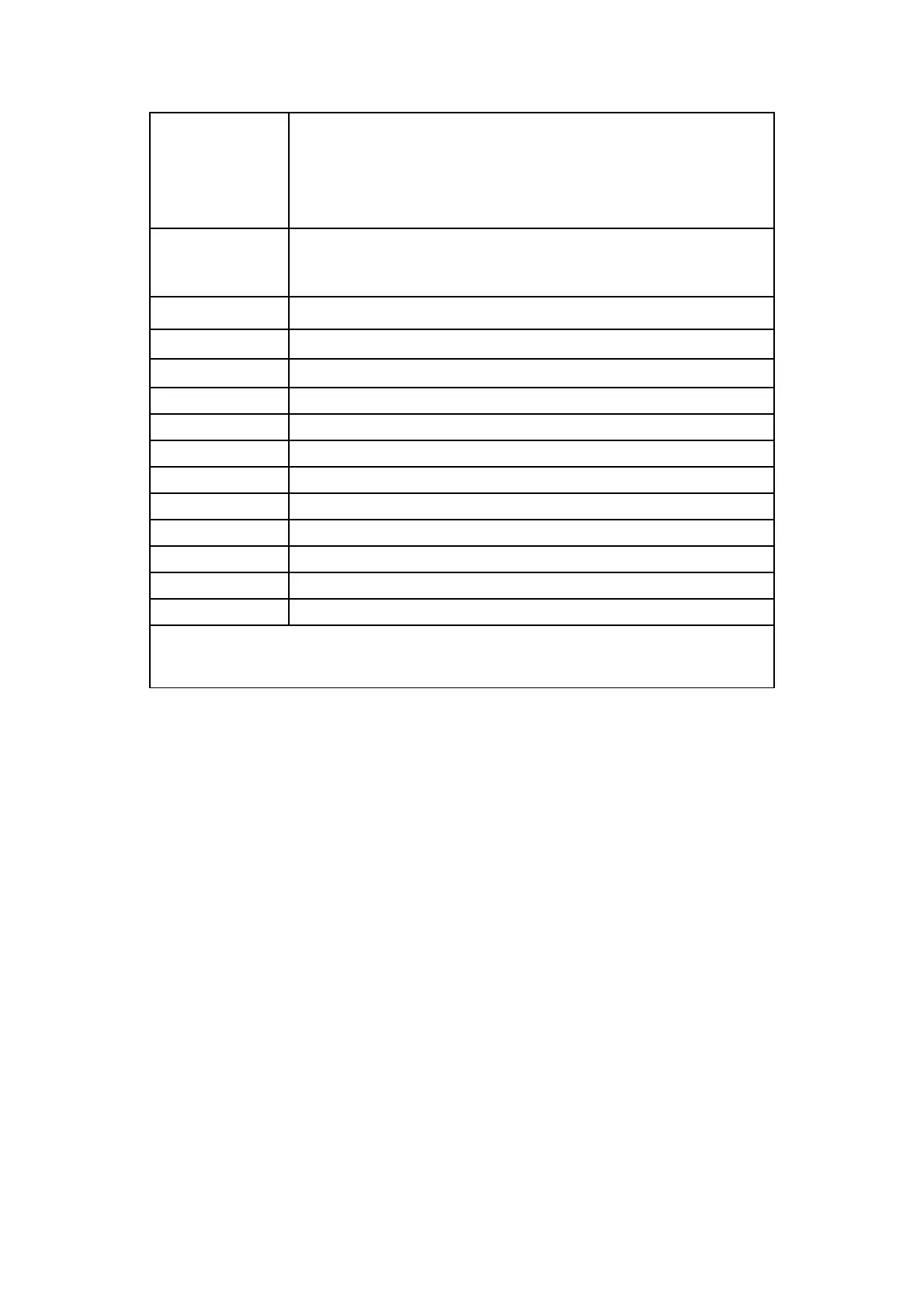

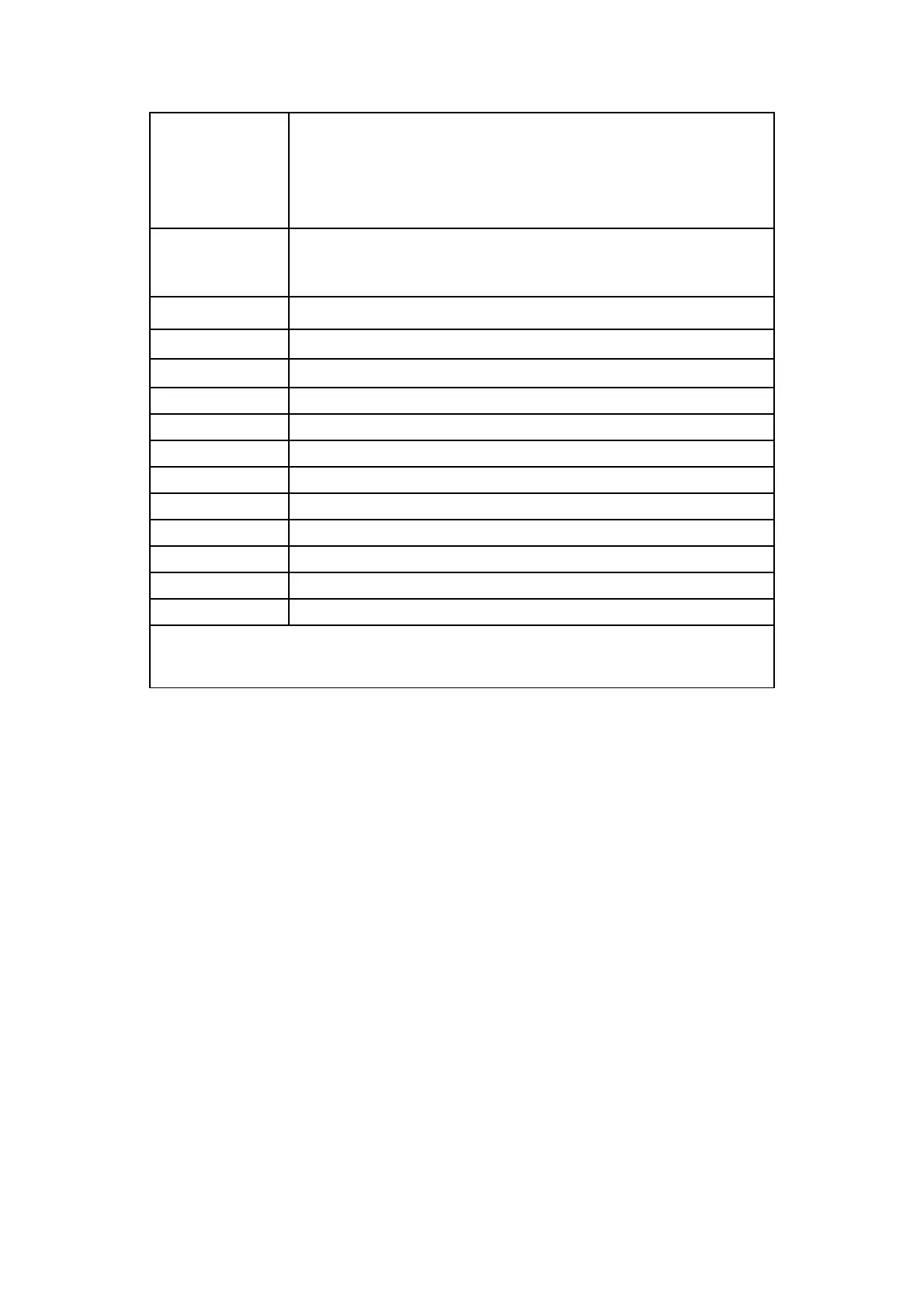

xArm is not ready.

Please check whether the errors have been cleared, whether the robot

arm has been enabled, and whether the robot arm status is set correctly.

Other error.

Please contact technical support.

The end tool Modbus baud rate is incorrect.

The end tool Modbus reply length error.

Trajectory read/write failed.

Trajectory read/write timeout.

Playback trajectory timeout.

Vacuum gripper wait timeout.

Waiting for completion timeout.

Too many failures to detect the status of the end effector.

There are errors in the end effector

The end effector is not enabled

For alarm codes that are not listed in the above table: enable the robotic arm and gripper. If

the problem remains unsolved after power on/off for multiple times, please contact technical

support.

xArm-Python-SDK Error Handling:

When designing the robotic arm motion path with the Python library, if

the robotic arm error (see Appendix for Alarm information) occurs, then

it needs to be cleared manually. After clearing the error, the robotic arm

should be motion enabled.

Python library error clearing steps: (Please check GitHub for details on

the following interfaces)

a. error clearing: clean_error()

b. Re-enable the robotic arm: motion_enable(true)

Loading...

Loading...