Varec, Inc. 99

Chapter 9

Troubleshooting

Friction is a common problem that affects gauge accuracy. Some liquids produce corrosion in

the mechanism. Periodic inspection and maintenance provided by a Varec service contract can

prevent problems from occurring. Periodic cleaning, lubrication, and replacement of worn

parts stops trouble before it starts.

Dials Do Not Respond When Gauge Check Knob is

Rotated

Caution Broken negator spring may cause injury. Stand clear of gauge head when remov-

ing back cover.

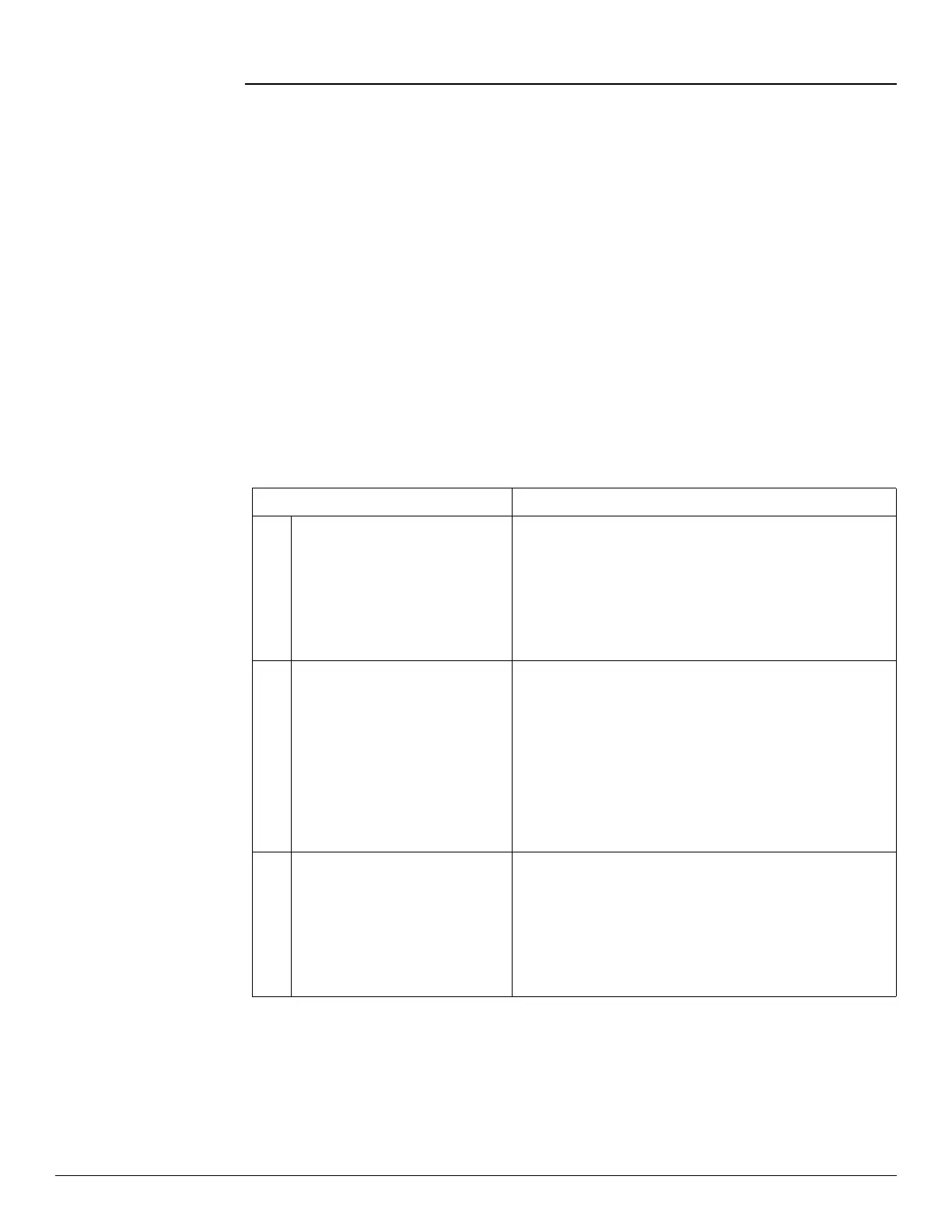

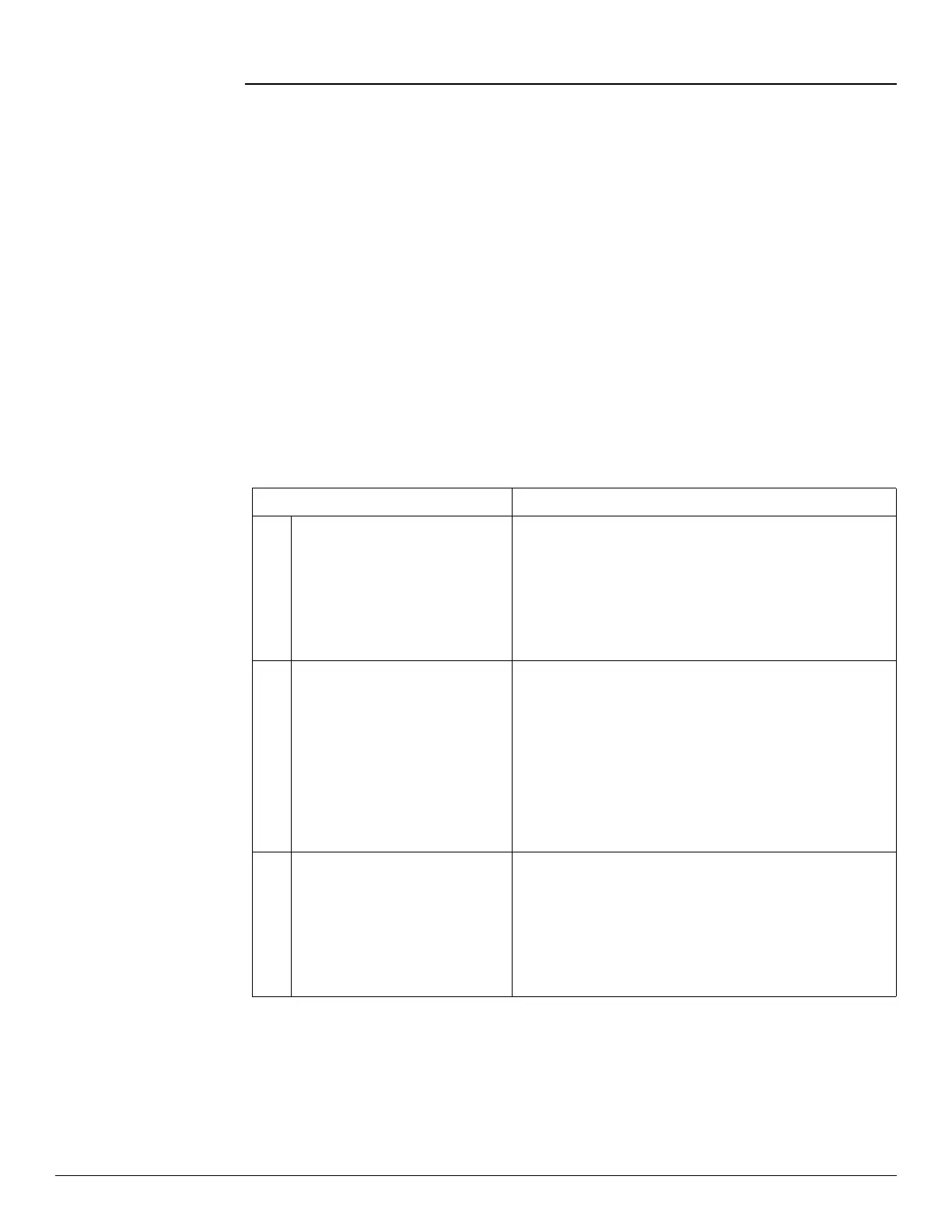

Possible Cause Action

1 Tape broken? Yes -

• Replace tape.

• Check attachment of negator motor to storage sheave.

• Check for damaged gauge parts.

No -

• Go to 2.

2 Negator motor broken? Yes -

• Replace negator.

• Do not redrill or repair.

• Wear gloves.

• Check tape condition.

• Check for damaged gauge parts.

No -

• Go to 3.

3 Tape rewound? Yes -

• Tape detached from float.

• Replace tape and re-attach.

• Check for damaged gauge parts.

No -

• Go to 4.

Loading...

Loading...