2500 Automatic Tank Gauge

28 Installation and Operations Manual

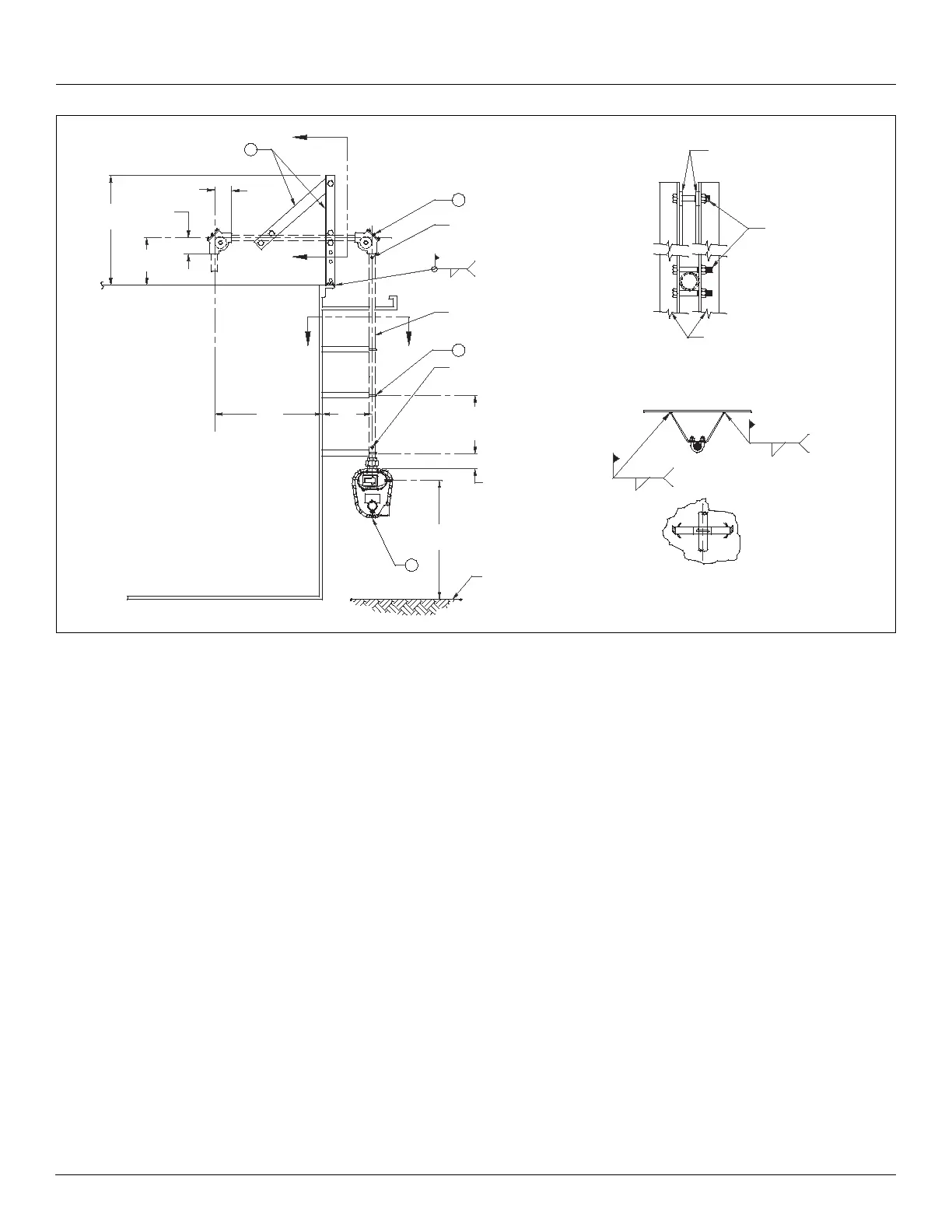

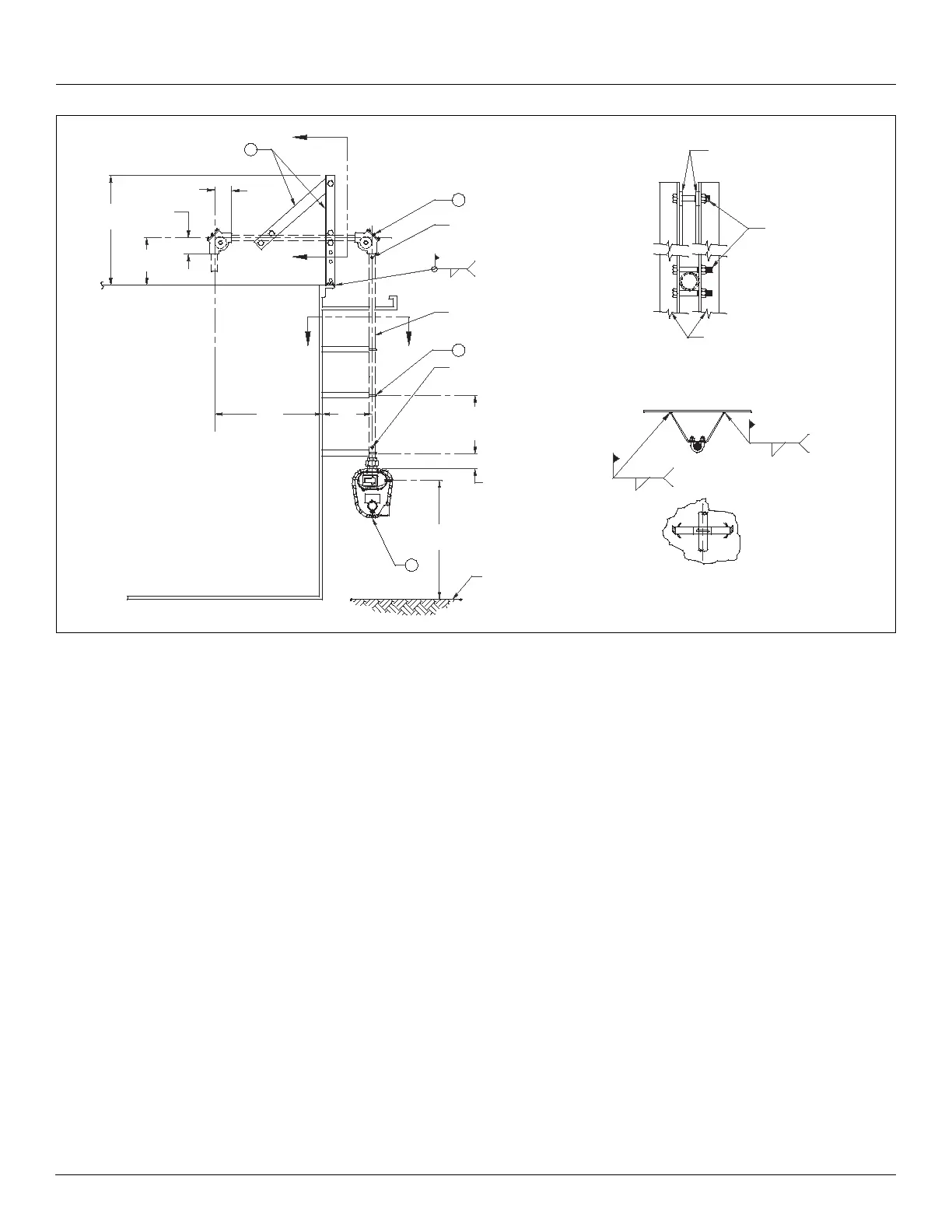

Figure 7: Example Support Bracket Installation

Installing a Gauge Head at Grade Level

Note Ensure you have completed all previous steps from your installation checklist

before proceeding.

Warning When removing the gauge head back cover, stand to one side as the last bolt is

removed. If the negator motor spring is broken, the broken pieces may cause injury when

the cover is removed.

1. Remove the back cover and gasket from the gauge head.

Note The weight of the installed gauge head is supported by the pipe and brackets.

2. Apply pipe thread compound and attach the gauge head to the exterior vertical pipe.

Position it for convenient reading.

.25

[6]

Convenient

eye level

Layout for pipe supports

spaced approximately at

10 foot [3 meter] intervals

47.75

[1213]

2[51] X 2[51] X .25[6.4]

Steel angle

View B - B

1

Maximum

36.00

[914]

16.00

[406]

Minimum

8.00

[203]

CC

72.00

[1829]

.25[6.4] X 1.5[38]

Steel flat bar

1/2-13 Hardware

4.50

[114]

4.50

[114]

7

B

B

Typical

View C - C

Grade

6.00

152]

.25

[6]

Tape / cable splice

at full tank

position

2 Places

1-1/2 Inch pipe and

fittings by customer

5

Typical

.25

[6]

Tape / cable splice

at empty tank

position

6

Loading...

Loading...