2500 Automatic Tank Gauge

100 Installation and Operations Manual

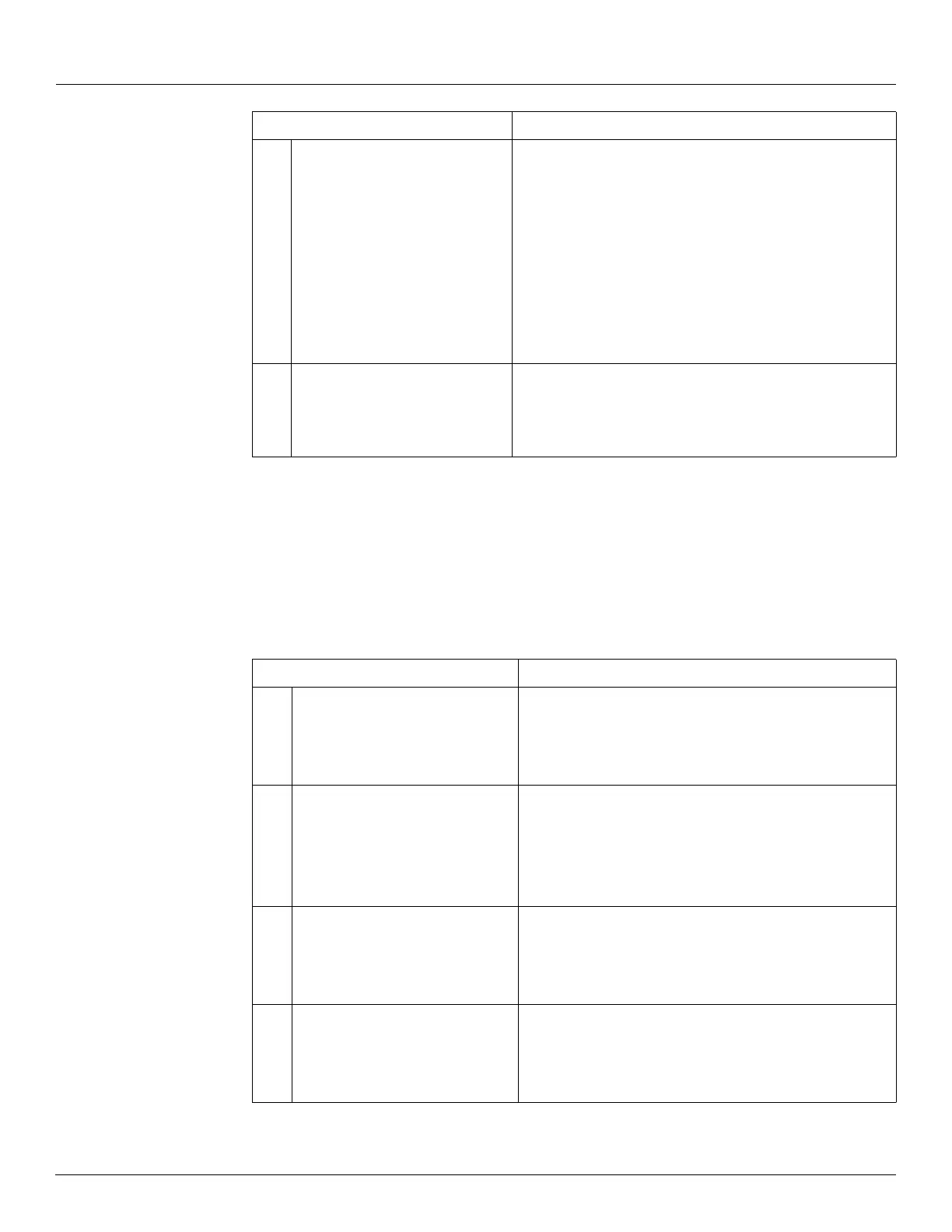

Table 12: Broken Negator Spring - Possible Cause / Action

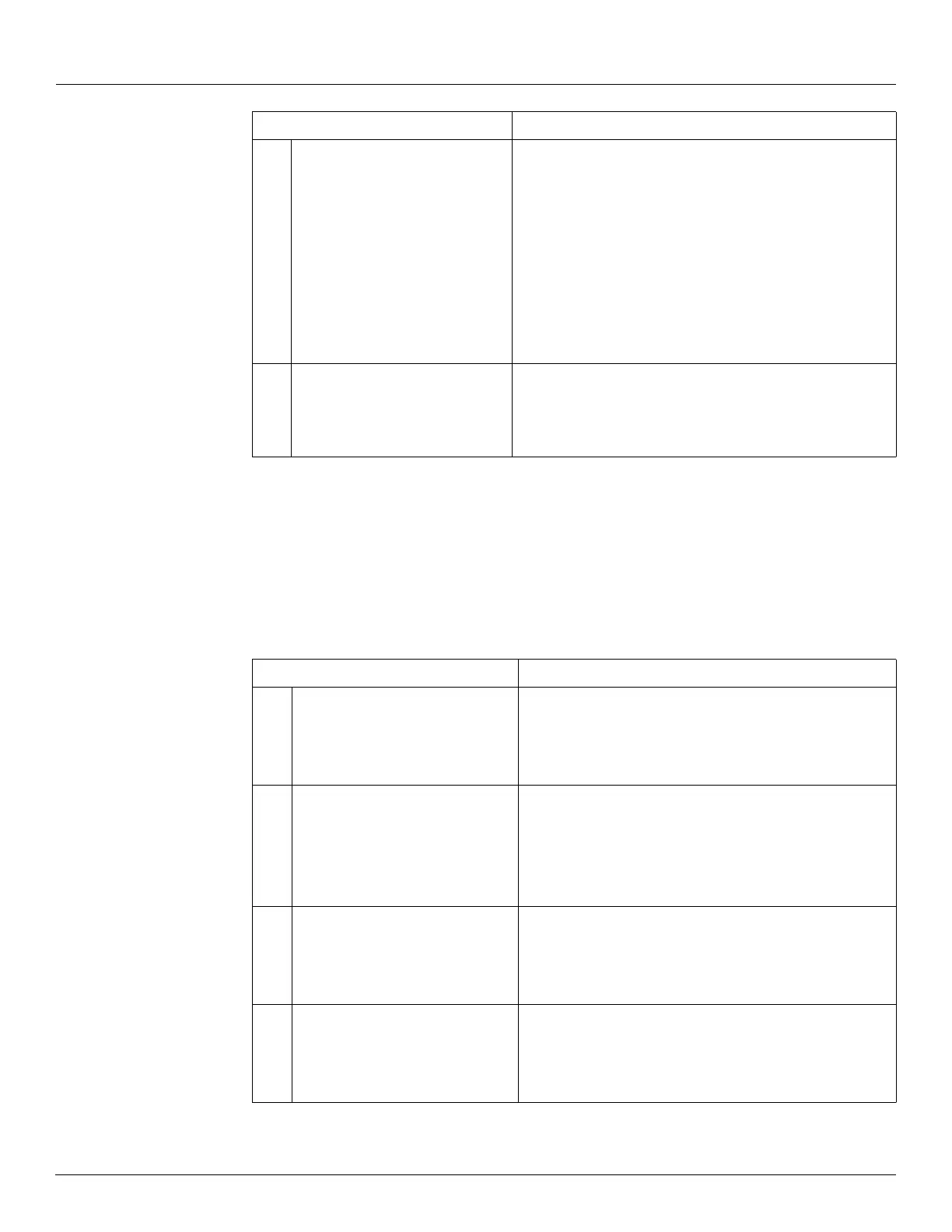

Calibration Repeatability Unstable

Caution Broken negator spring may cause injury. Stand clear of gauge head when remov-

ing back cover.

4 Dials stopped? Yes -

• Check for frozen tape sprocket sheave shaft. Repair/

replace.

• Check for frozen accessory shaft. Repair/replace.

• Check dial gear engagement with pinion gear. Adjust/

replace.

• Check gauge checker for broken spring and damaged

ratchet pawl. Replace.

No -

• Go to 5.

5 Counter dial wheels stopped; dial

rotates?

Yes -

• Check for worn/broken counter pinion gear and counter

wheels.

• Replace as necessary.

Possible Cause Action

Possible Cause Action

1

Dirty gauge housing? Yes -

• Clean with automotive-type spray degreaser.

No -

• Go to 2.

2

Tape or cable off elbow pulley? Remove elbow covers.

Yes -

• Reseat and lubricate the gauge.

No -

• Go to 3.

3

Elbow pulley shaft or bushing is

worn or?

Yes -

• Repair or replace

No -

• Go to 4.

4

Tape conduit dirty? Yes -

• Remove and clean.

No -

• Go to 5.

Loading...

Loading...