2500 Automatic Tank Gauge

46 Installation and Operations Manual

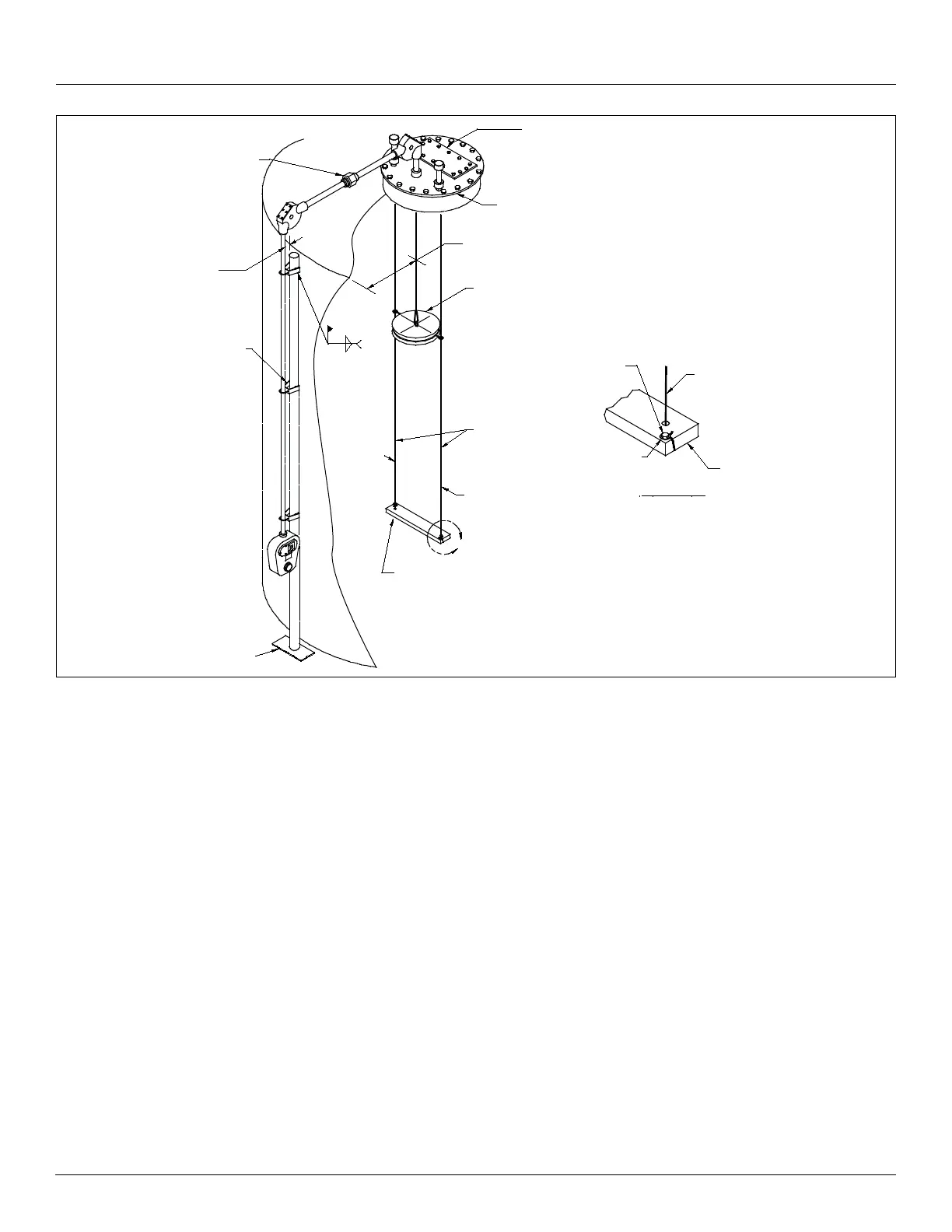

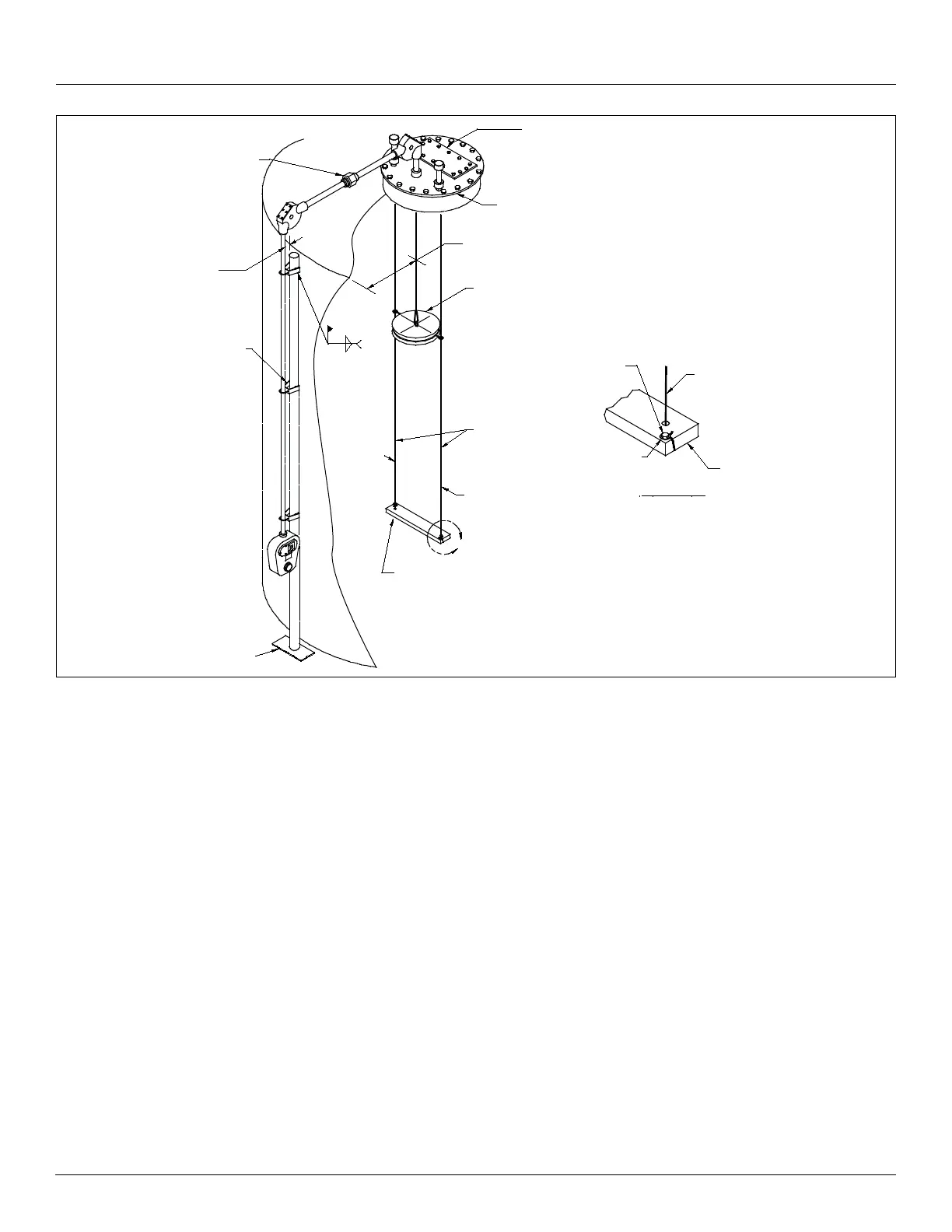

Figure 1: Typical In-Service-Tank Installation with Manhole, Inspection Hatch, and Independent

Pipe Support Structure. Detail “A” shows in-service bottom anchor.

Negator Cassette Installation

Varec's negator cassette is a fully enclosed design to safely contain a damaged or failed negator

motor. It will extend negator motor life by keeping pipe scale and debris off the negator motor.

The cassette provides quick and easy change out of any future negator motor failures.

Caution Damage to equipment may result if this precaution is disregarded.

Warning Direct injury to personnel or damage to equipment which can cause injury to

personnel may result if this precaution is not followed.

Disassembly

Perform the following steps to prepare the gauge head for installation of the negator motor

cassette. For part number reference, refer to Figure 11 on page 77.

1. Note and record gauge-level reading.

Float guide

cables

Guided float

36.00 [914] Maximum

16.00 [406] Minimum

Existing standard roof manhole

with gasket & mounting hardware

Pipe support

brackets for

welding to

customer support

structure.

Space brackets

approximately at

10 foot [3 meter]

intervals.

17.00

[432]

In service anchor weight

ordered separately

9 [229]

Space

approximate

Piping and fittings

furnished by customer

Inspection Cover

For existng 20-inch and larger

manhole covers

See details B & C

.25

[6]

Typical

Support structure

set in concrete

Float guide

cable

Anchor weight

Cable clamps

Hex head

cap screw

DETAIL: A

Loading...

Loading...