2500 Automatic Tank Gauge

42 Installation and Operations Manual

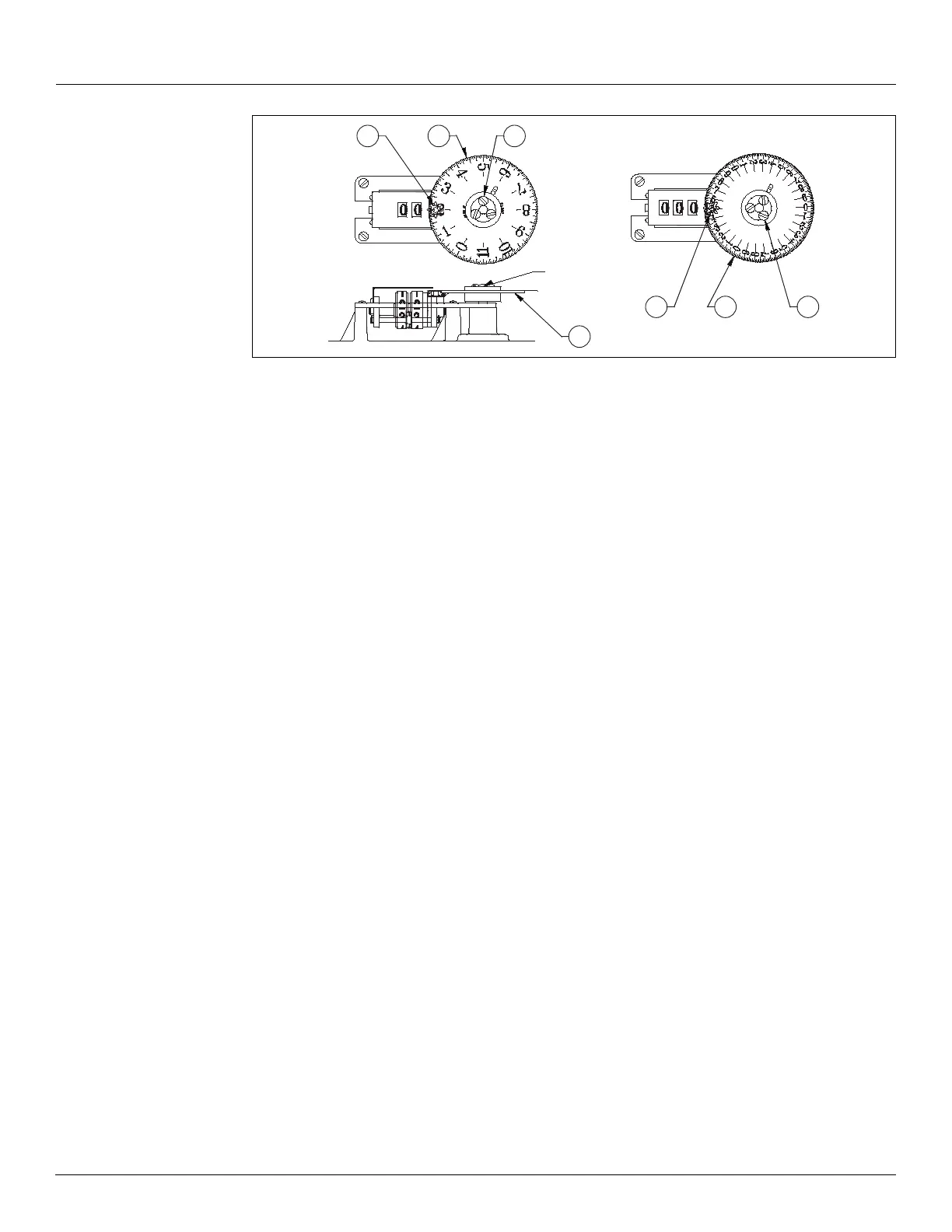

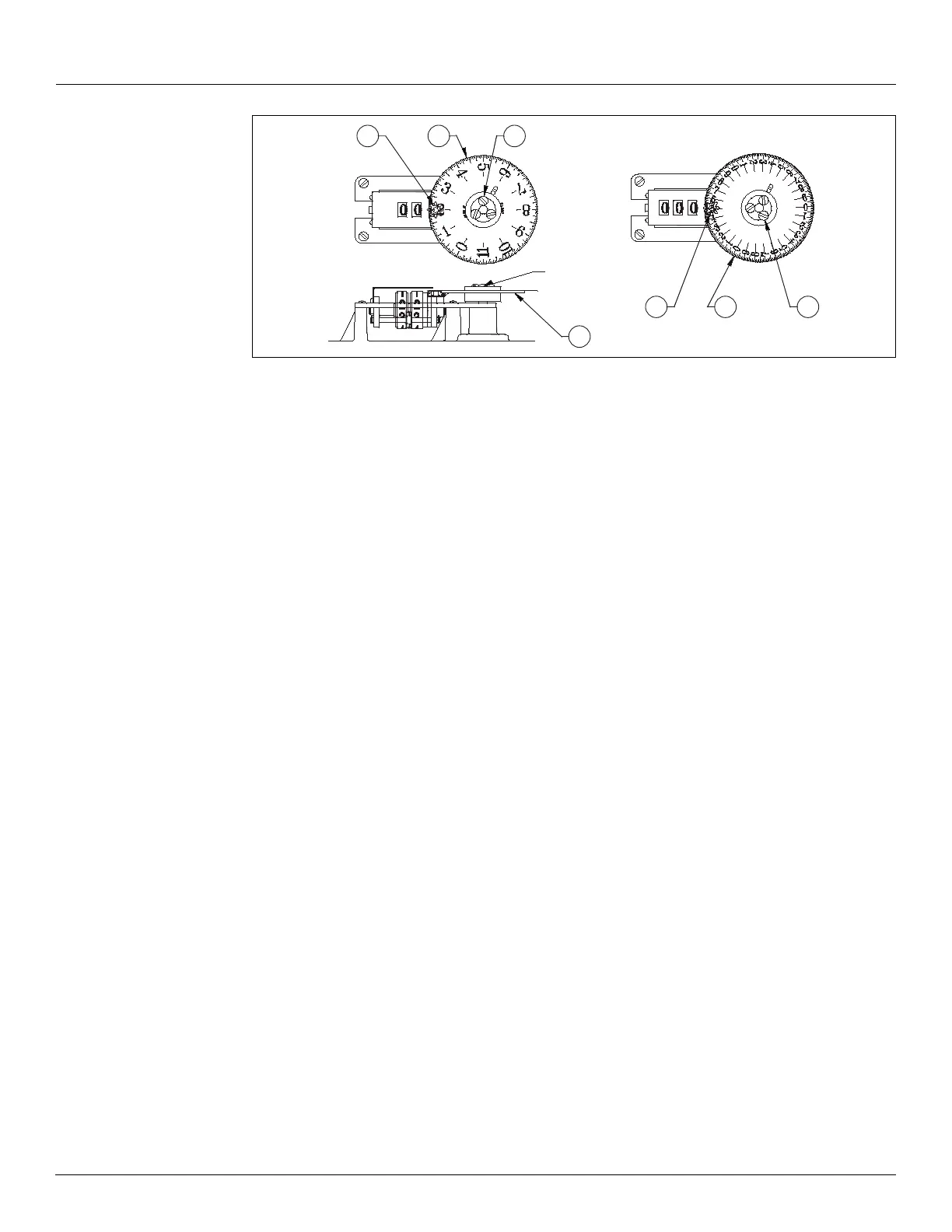

Figure 16: Dial Plate Adjustments

Initial Lubrication

Note Ensure you have completed all previous steps from your installation checklist

before proceeding.

Caution Gauges measuring caustic liquids require that the gauge head be oil-filled.

Failure to protect the gauge head with oil may result in damage.

Note Refer to Section "Lubrication" on page 71 for recommended oil.

1. Apply a light oil to the elbow sheave.

2. If the gauge head is not going to be filled with oil, apply a light oil to the tape sprocket and

storage sheave.

3. If the gauge head is to be filled with oil, reassemble the gauge head, then fill with oil. For

most service, Varec recommends filling the gauge head with oil to reduce wear and pro-

long the service life.

Note To fill the counter assembly side of the gauge head with oil, it is necessary to

change the bottom NPT condensate drain plug. Replace it with a solid 1/4”-NPT plug or

reverse the solid top plug with the bottom plug. Fill the hole in the condensate drain plug

with RTV 737 sealant.

4. If your installation requires oil seals on the tape-run conduit elbows refer to Section "Oil

Seal Installation" on page 49.

Install a Transmitter and Replace all Covers

Note Be sure to read Chapter 2 on page 7 before proceeding with this installation.

Ensure you have completed all previous steps from your installation checklist before pro-

ceeding.

Caution Do not store the installation crank and thumbscrew in the gauge head, but keep

them at a storage area for future use.

English Fractional

Metric

24

7

40

24

7

40

5

Hub Assembly

Loading...

Loading...