Varec, Inc. 17

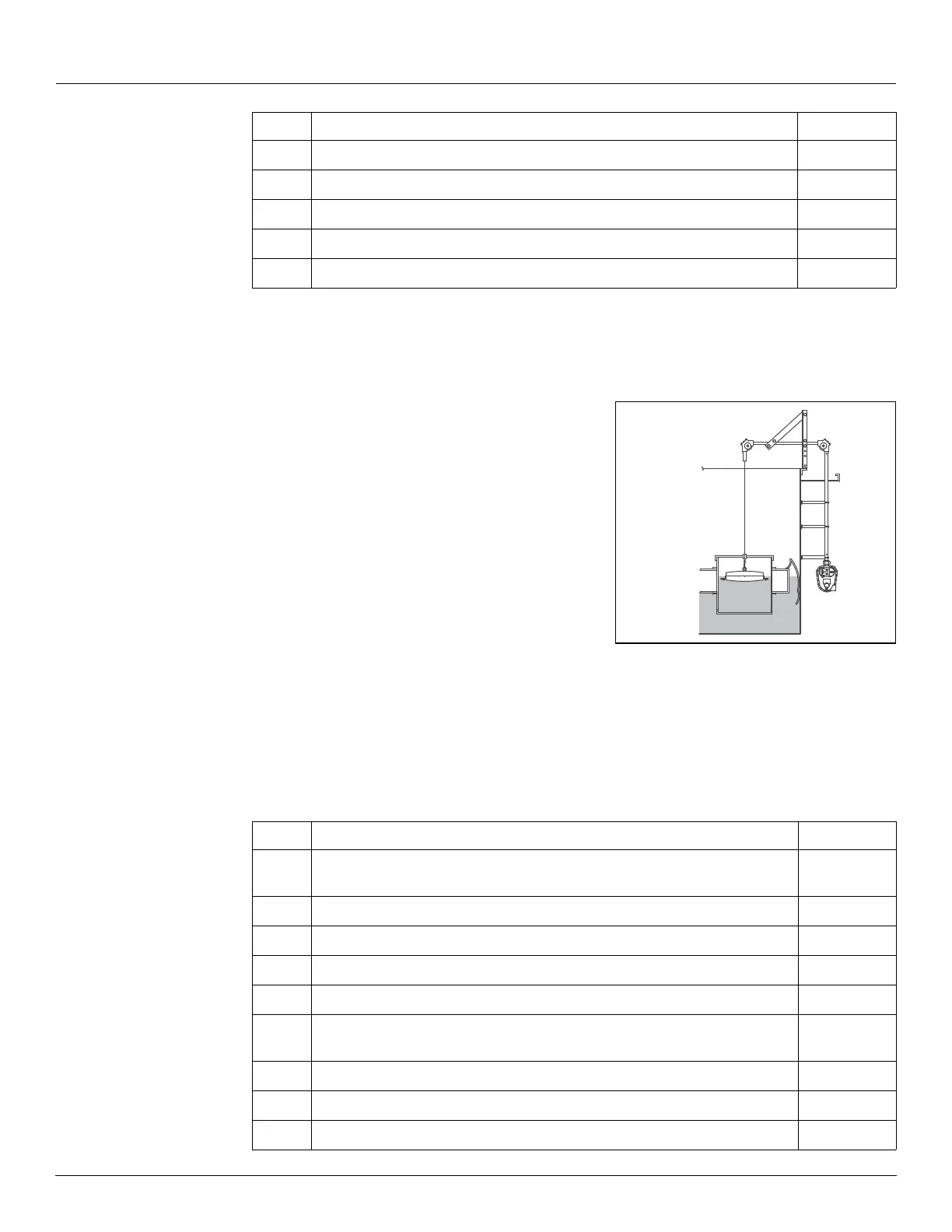

Table 7: Stilling Well Service Cone Roof Tank 6" Diameter Float — Installation Checklist

External Floating Roof Tank and Floatwell

Order Code T03, T13

Installation parts supplied include:

• 90° Elbow assembly (x2)

• Gauge 'U' bolt kit

• Support bracket assembly

• Support bracket (x6)

• gauge head and tape/cable

• Float

• Tape/cable connectors

Figure 11: External Floating Roof Tank and Floatwell

Installation Checklist

When installing a 2500 ATG system on a External Floating Roof Tank and Floatwell, complete

each installation step below. Check off a step when it is complete. Refer to Section

“Installation Schematics” on page 21 for overall dimensions.

8

Section “Reset the Counter” on page 40

9

Section “Calibrate the Counter” on page 41

10

Section “Initial Lubrication” on page 42

11

Section “Install a Transmitter and Replace all Covers” on page 42

12

Section “Initial Operation” on page 43

Step Description Complete

Step Description Complete

1

Section “Correct Float Positioning for an External Floating Pan Installation”

on page 25

2

Section “Installing Support Brackets & Pipework” on page 27

3

Section “Installing a Gauge Head at Grade Level” on page 28

4

Section “Float installation on an Out-of-Service Tank” on page 30

5

Section “Connecting the Cable to a Float in a Floatwell” on page 31

6

Section “Feeding the Tape to a Gauge Head Located at Grade Level” on

page 34

7

Section “Install Tape in the Gauge Head” on page 35

8

Section “Trimming the Cable at the Float in a Floatwell” on page 39

9

Section “Reset the Counter” on page 40

Loading...

Loading...