2500 Automatic Tank Gauge

38 Installation and Operations Manual

5. Lock the crank assembly into the case keyhole slot before releasing your grip on the han-

dle.

6. At the gauge head, put the first hole in the tape on a pin of the sprocket close to the tape

guide.

7. Rotate the sprocket clockwise to pull the tape through the guide.

8. Pull the tape around the storage sheave.

9. Fasten the 2nd hole in the tape to the tape storage sheave on the sheave pin.

10. Turn the storage sheave counter-clockwise to wind up all excess tape.

11. Reinstall the Negator Cassette with crank assembly into gauge head. Reinstall the two

socket head screws. Grasp the installation crank firmly and unlock it from the case. Allow

the handle to rotate to remove any additional tape slack.

12. Check the tape path between the float and the gauge head to be sure that it is not kinked

or twisted.

Caution Do not attempt to hand crank the float above (through) a floating roof. Hand-

cranking the tape beyond this point on a floating roof installation can damage and snap

the tape!

With a Hand Crank Gauge Head

Caution Do not disengage the hand crank, while the float is off the bottom of the empty

tank or above the surface of a product. A free fall may damage the float or the gauge. Make

certain that the hand crank is disengaged when the float is returned to the tank bottom or

to the surface of the product. Damage to the gauge and inaccurate measurements may

result.

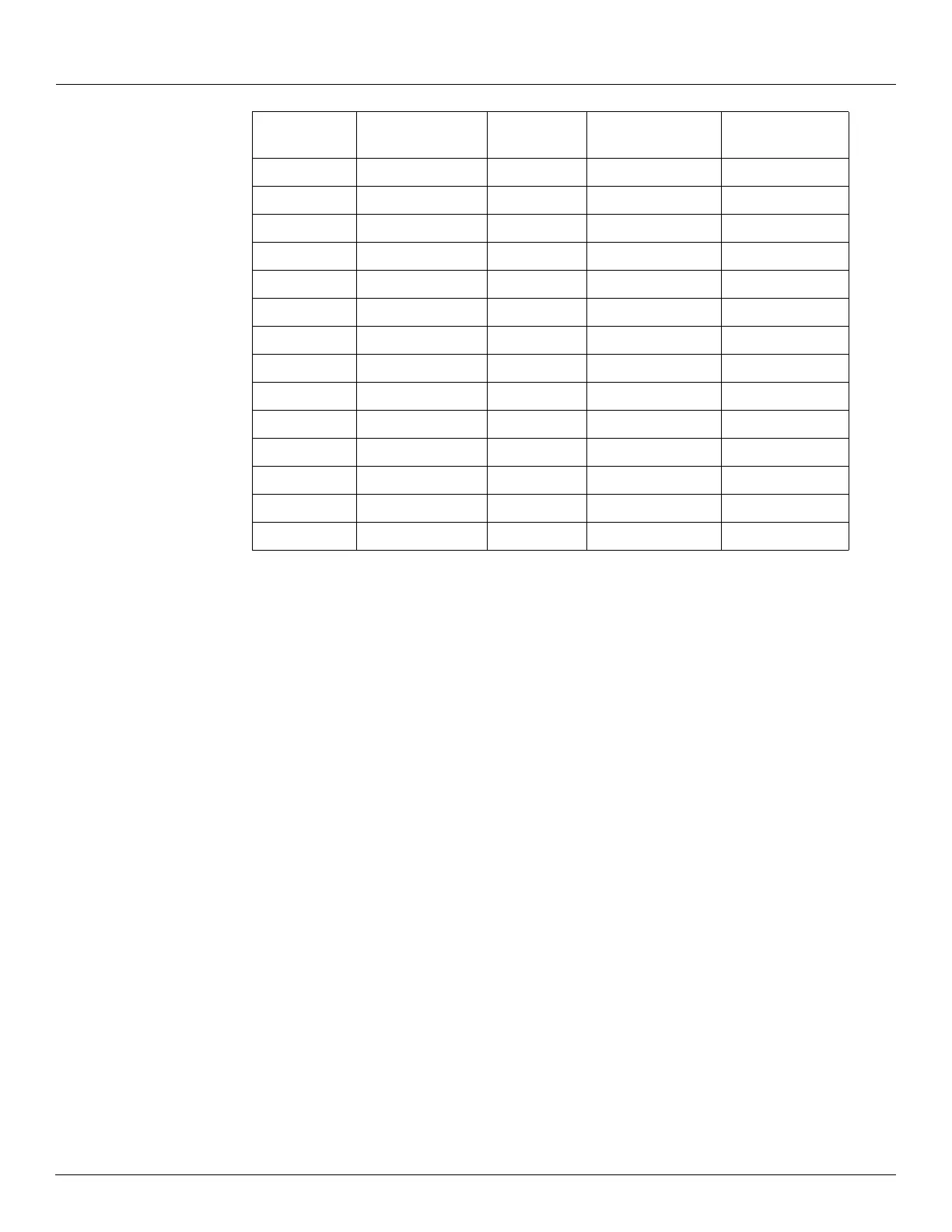

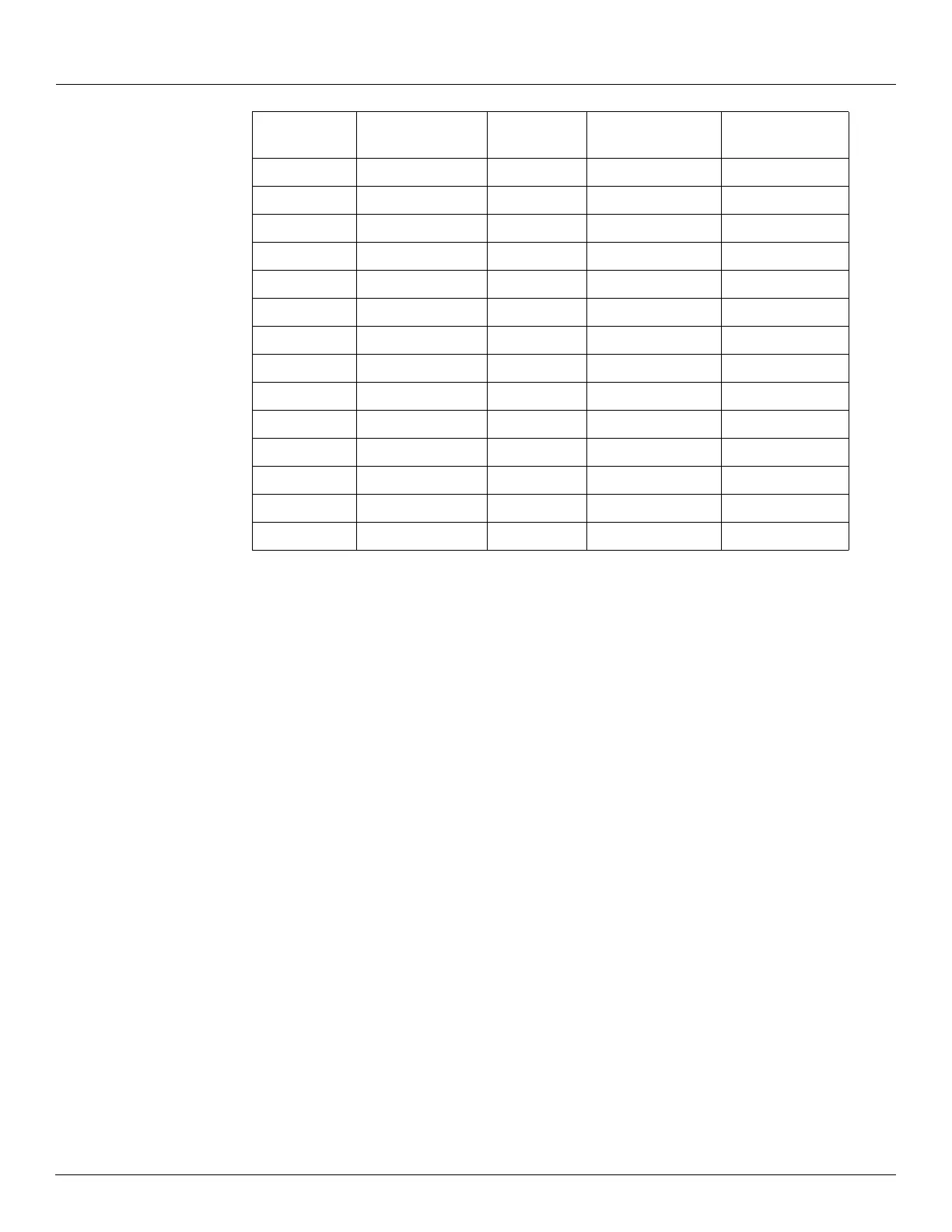

40 12.2 26 7.9 19

42 12.8 24 7.3 18

44 13.4 22 6.7 16

46 14.0 20 6.1 15

48 14.6 18 5.5 14

50 15.2 16 4.9 13

52 15.8 14 4.3 11

54 16.5 12 3.7 10

56 17.1 10 3.0 9

58 17.7 8 2.4 8

60 18.3 6 1.8 6

62 18.9 4 1.2 5

64 19.5 2 0.6 4

66 20.1 0 0.0 3

Innage Tank

Level (ft)

Innage Tank Level

(m)

Outage Tank

Level (ft)

Outage Tank Level

(m)

Number of Turns

(Neg. Cassette)

Table 2: Innage and Outage Turns of the Negator Cassette (continued)

Loading...

Loading...