INSTALLATION CUTMASTER 10MM, 12MM

Manual 0-5230 3-3 Installation

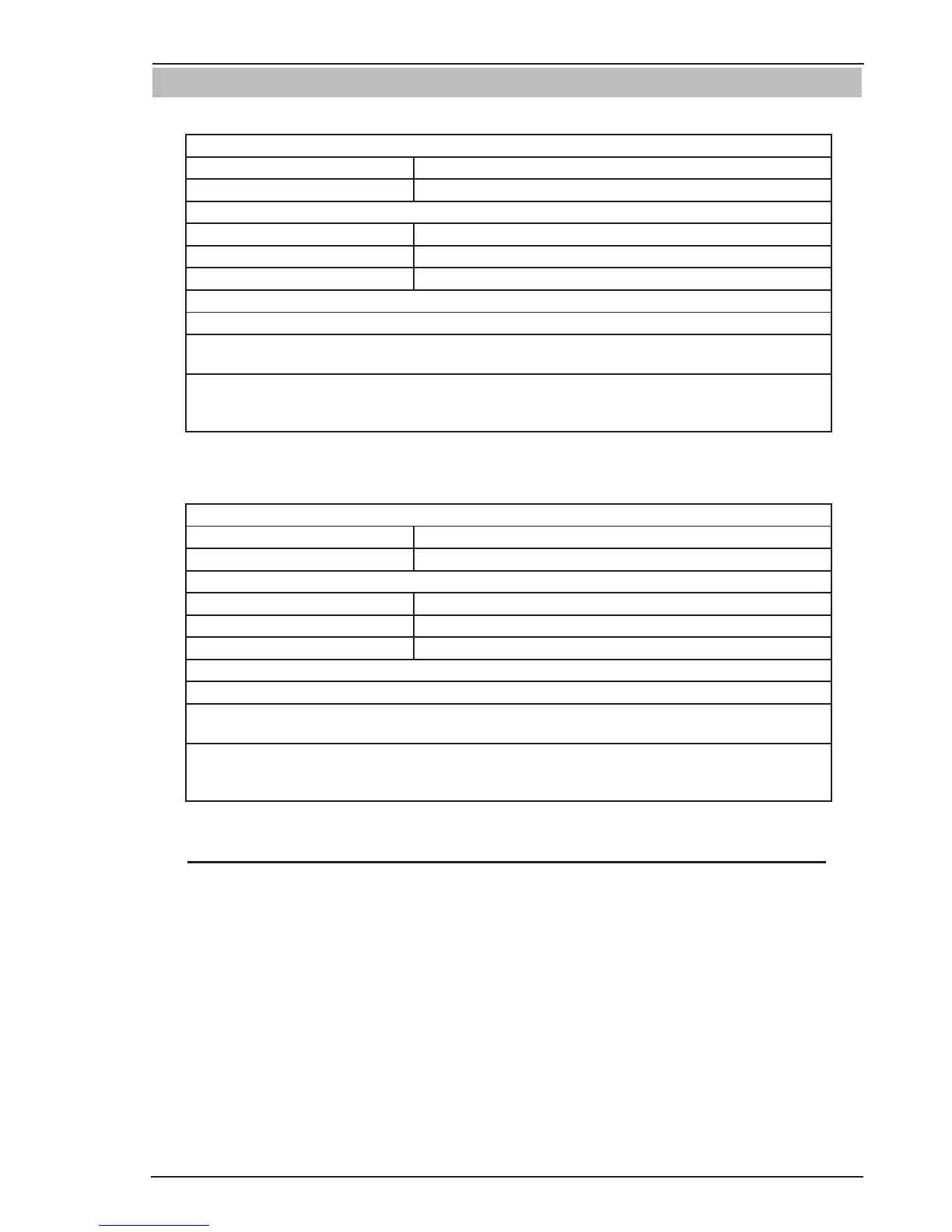

3.04 Power Source Specifications

A. CutMaster 10mm Plant Part No. 1-4730-6

CUTMASTER 10mm Power Source Specifications

Input Power 240 VAC (+/-15%), 1 Phase, 50/60Hz

Output Current 20-30 Amps @ 240VAC

CUTMASTER 10mm Power Source Duty Cycle (Note 1)

Ambient Temperature 104° F (40° C)

Duty Cycle 40% @ 240VAC

Rated Current 30 Amps @ 240VAC

SL60 Torch Gas Requirements (See Section 2T.02)

Note

Note 1: Duty Cycle is the percentage of time the system can be operated without overheating. Duty cycle is

reduced if primary input voltage (AC) is low or the DC voltage is higher than shown in this chart.

Note 2: Air supply must be free of oil, moisture, and other contaminants. Excessive oil and moisture may

cause double-arcing, rapid tip wear, or even complete torch failure. Contaminants may cause poor cutting

performance and rapid electrode wear. Optional filters provide increased filtering capabilities.

Table 3-3- CUTMASTER 10mm Plant Power Source Specifications

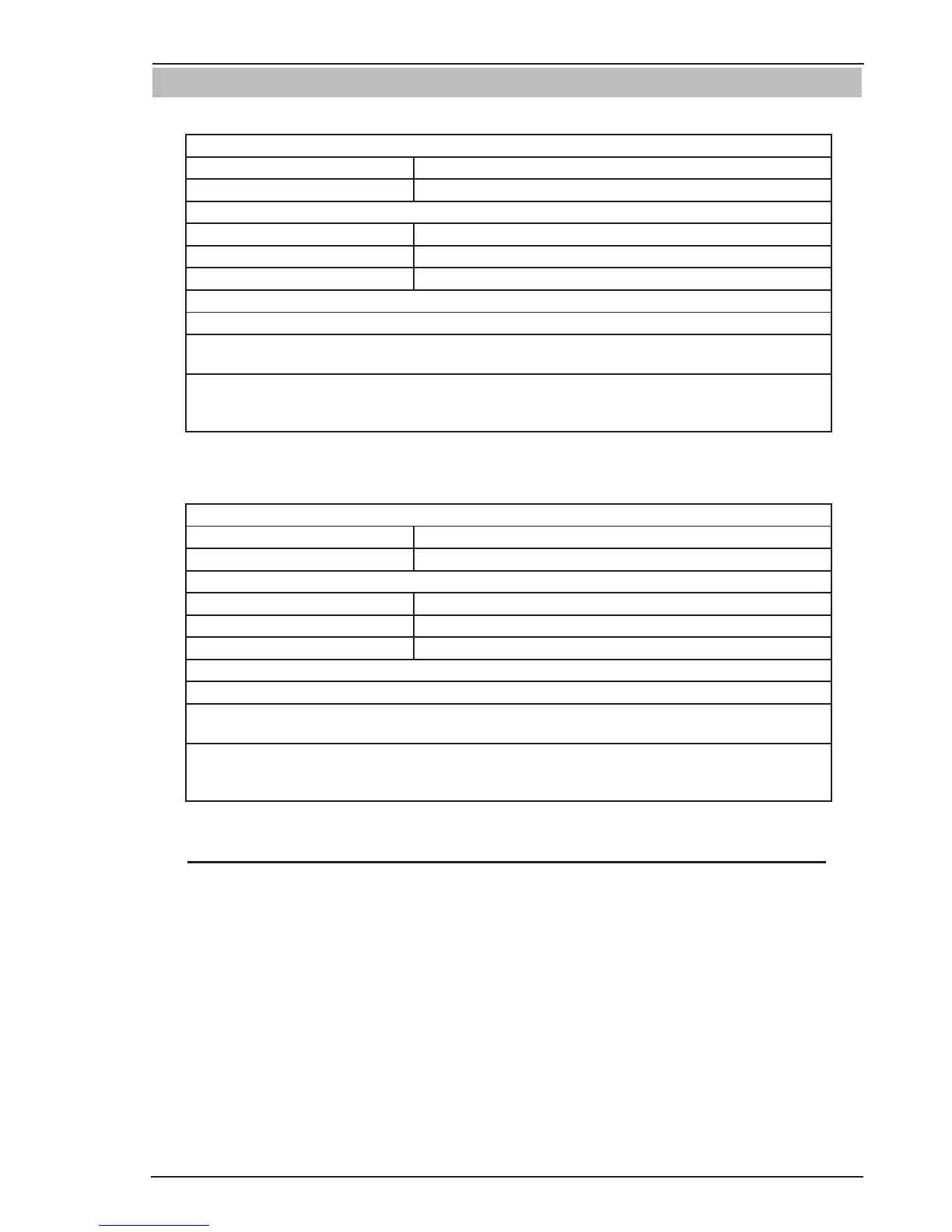

B. CutMaster 12mm Plant Part No. 1-4200-6

CUTMASTER 12mm Power Source Specifications

Input Power 240 VAC (+

-

15%), 1 Phase, 50/60Hz

Output Current 20-40 Amps @ 240VAC

CUTMASTER 12mm Power Source Duty Cycle (Note 1)

Ambient Temperature 104° F (40° C)

Duty Cycle 40% @ 240VAC

Rated Current 40 Amps @ 240VAC

SL60 Torch Gas Requirements (See Section 2T.02)

Note

Note 1: Duty Cycle is the percentage of time the system can be operated without overheating. Duty cycle is

reduced if primary input voltage (AC) is low or the DC voltage is higher than shown in this chart.

Note 2: Air supply must be free of oil, moisture, and other contaminants. Excessive oil and moisture may

cause double-arcing, rapid tip wear, or even complete torch failure. Contaminants may cause poor cutting

performance and rapid electrode wear. Optional filters provide increased filtering capabilities.

Table 3-4- CUTMASTER 12mm Plant Power Source Specifications

NOTE

IEC Rating is determined as specified by the International Electro-Technical Commission. These speci-

fications include calculating an output voltage based upon power supply rated current. To facilitate

comparison between power supplies, all manufacturers use this output voltage to determine duty cycle.

TDC Rating is determined using an output voltage representative of actual output voltage during cut-

ting with a TDC torch. This voltage may be more or less than IEC voltage, depending upon choice of

tor

ch, consumables, and actual cutting operation.

Loading...

Loading...