94

CHAPTER 6 - DETAILED PARAMETER DESCRIPTION

Range

[Factory Setting]

Parameter Unit Description / Notes

P520 0.0 to 999 %

PID Proportinal [ 100 ]

Gain 0.1(< 100)

1 (> 99.9)

P521 0.0 to 999 %

PID Integral [ 100 ]

Gain 0.1(< 100)

1 (> 99.9)

P522 0.0 to 999 %

PID Differential [ 0 ]

Gain 0.1(< 100)

1 (> 99.9)

The integral gain can be defined as being the time

required to vary the PI regulator output from 0 to P134,

That is given, in seconds, by the equation below:

t =

1600

P521.P525

For the following conditions:

- P040 = P520 = 0;

- Dix in automatic position.

P525 0.0 to 100.0 %

PID Regulator [ 0.0 ]

Set point 0.1 %

(Via Keys)

Provides the set point (reference) of the process via

keys and for PID regulator since P221 = 0

(local) or P222 = 0 (remote) and it has been set to

automatic mode. If it has been set to manual mode

the keys reference is provided by P121

If P120 = 1 (active backup), the value of P525 is

maintained at the last set value (backup), even when

the inverter is disabled or not energized.

P526 0.0 to 10.0 s

Process Varible [ 0.1 s ]

Filter 0.1

Sets the time constant of the process variable filter.

It is useful for noise filtering at the analog input AI1

(feedback of the process variable).

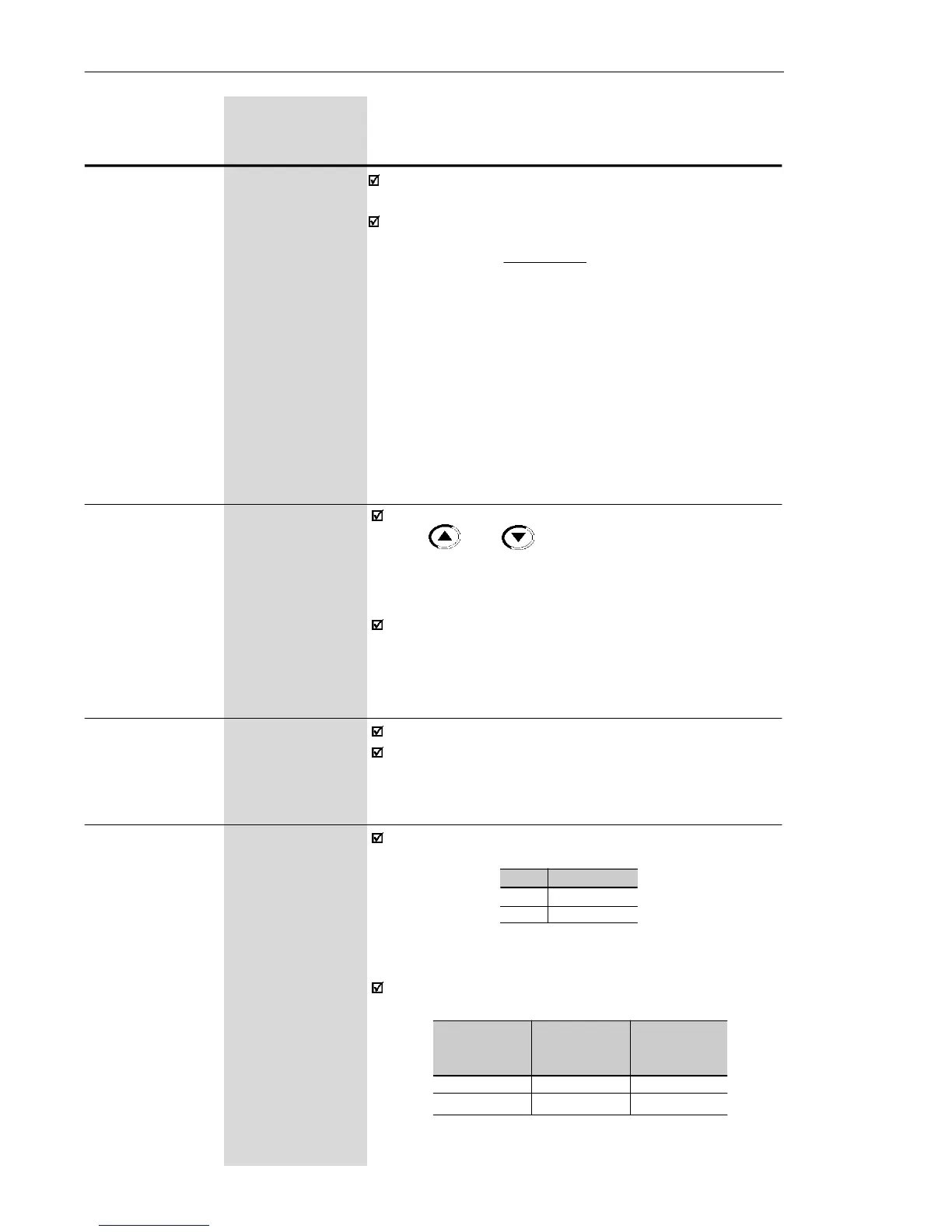

P527 0 to 1

Action Type of [ 0 ]

PID Regulator -

Defines the action type of the PID control.

Select according to the table below:

Increase

Increase

For this the

motor speed

must

Process

variable

requirement

Increase

Decrease

P527

to be

used

1(Reverse)

0 (Direct)

P527

0

1

Action Type

Direct

Reverse

Table 6.16 - PID action type configuration

Table 6.17 - Options operation description for P527

Loading...

Loading...