Maintenance

9.4 Performing a visual inspection

182

Operator’s Manual | 4080T Basic Line | 1000408123 | 05/2019 | [en]

9.4

Performing a visual inspection

9.4.1

Checking components

Check the following components daily:

• Check all steel parts for damage and loose threaded fittings, in partic-

ular the protective ROPS/FOPS structure.

• Check the condition and function of the seat belt.

• Check the power coupler for the attachment.

• Check whether all pivot pins are in their correct positions and secured

with their locks.

• Check the climbing aids and handholds for correct position.

• Check cab windows for breaks, cracks and stone chips.

• Check the condition of the lights and work lights.

• Check the tires for damage and penetration of sharp-edged objects.

• Check tires for wear.

• Check the condition of all safety labels and warning labels.

9.4.1.1

Checking wear plates of the telescopic boom

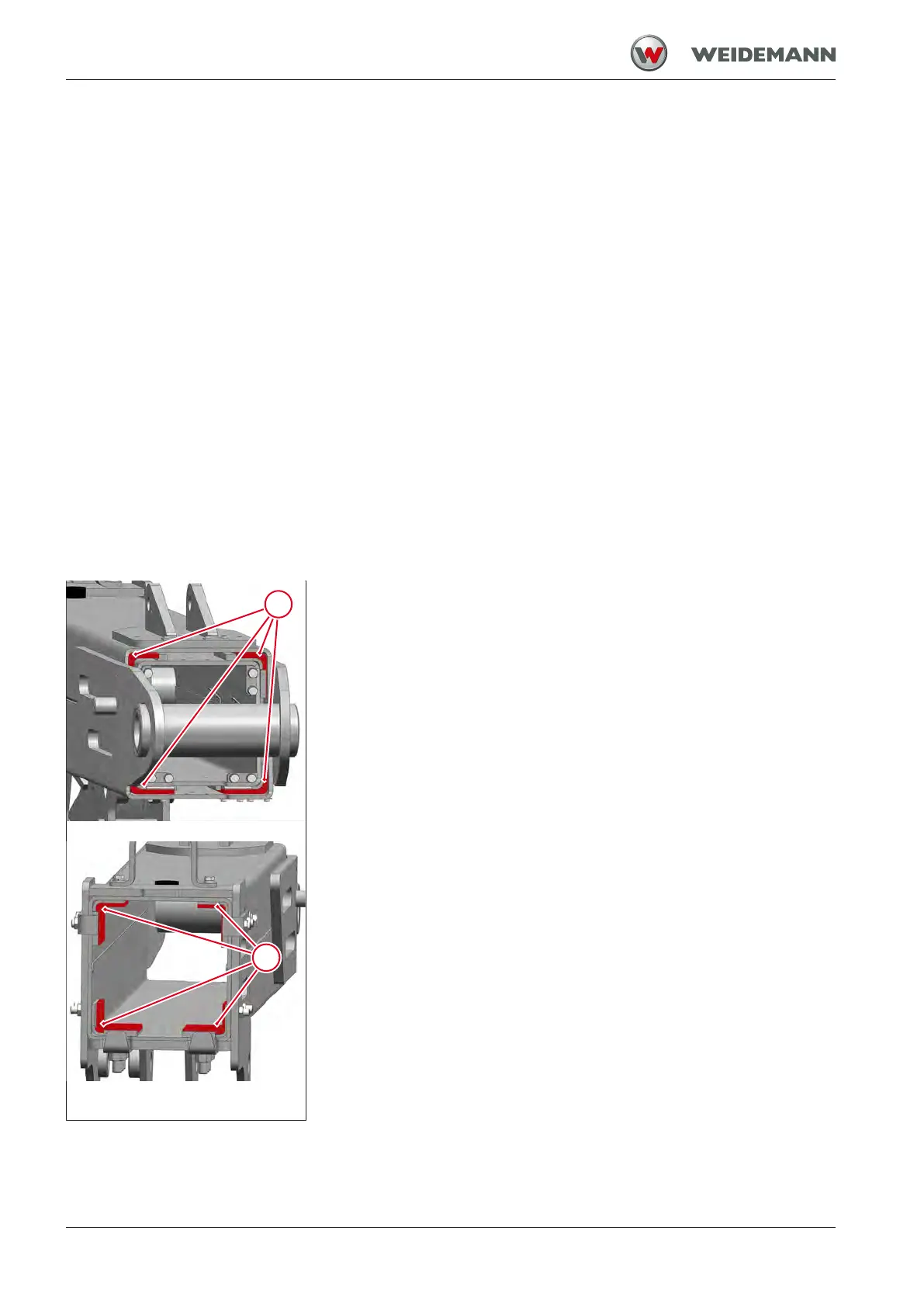

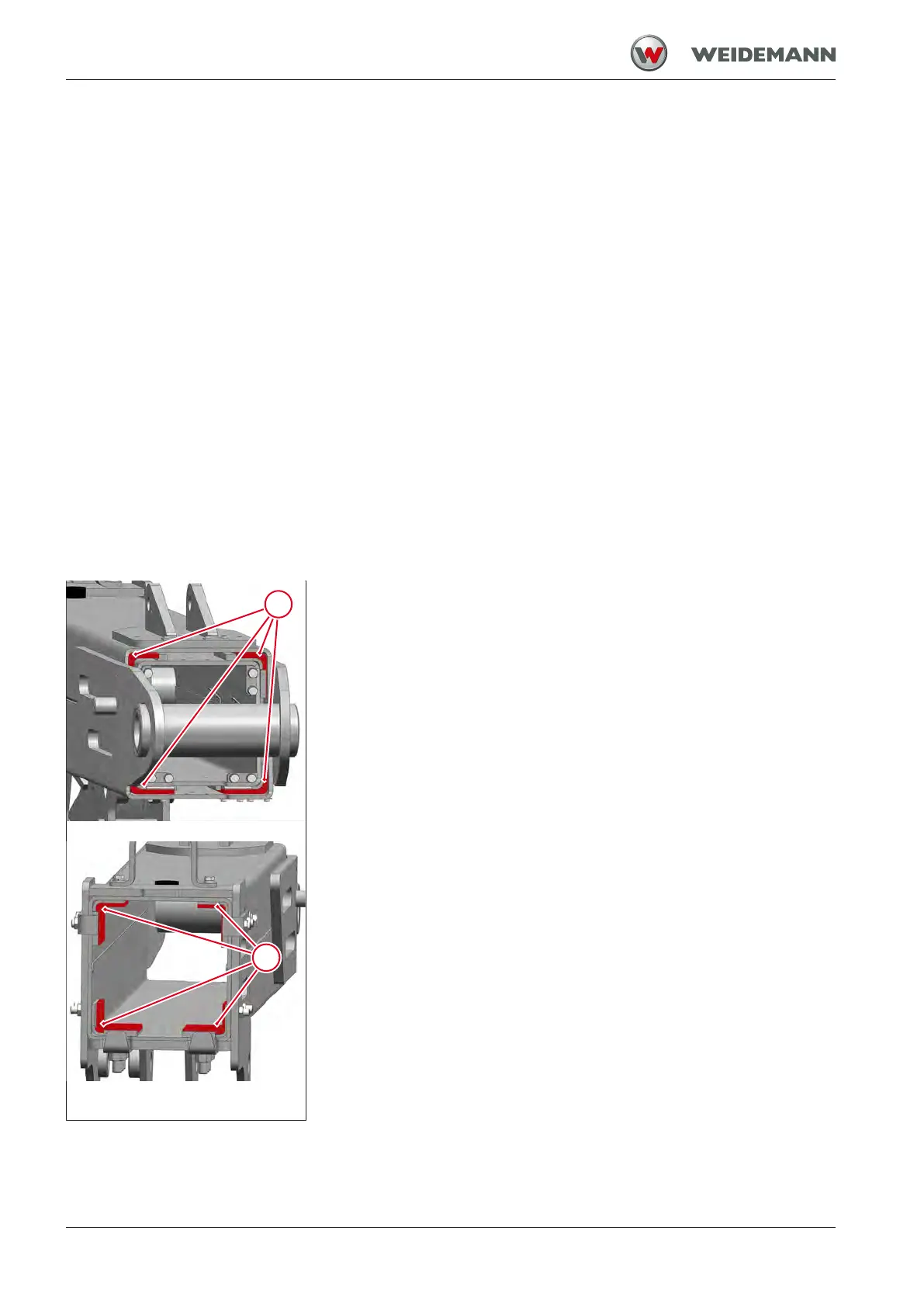

Fig.176: Plain bearing plates on

telescopic boom

Position I shows the slide bearing plates at the rear of the loader unit

Position II shows the slide bearing plates at the front of the loader unit.

The slide bearing plates at the front become visible when the loader unit

is telescoped.

1. Check the slide bearing plates at the rear for wear.

2. Check the slide bearing plates at the front for wear.

If the wear condition is too high, the inner tube of the loader unit is no

longer guided correctly and the loader unit begins to strike. Have the slide

bearings replaced by an authorized service center.

Loading...

Loading...