Maintenance

Lubricating the vehicle and attachment 9.7

199

[en] | 05/2019 | 1000408123 | 4080T Basic Line | Operator’s Manual

9.7.3

Lubricating attachments

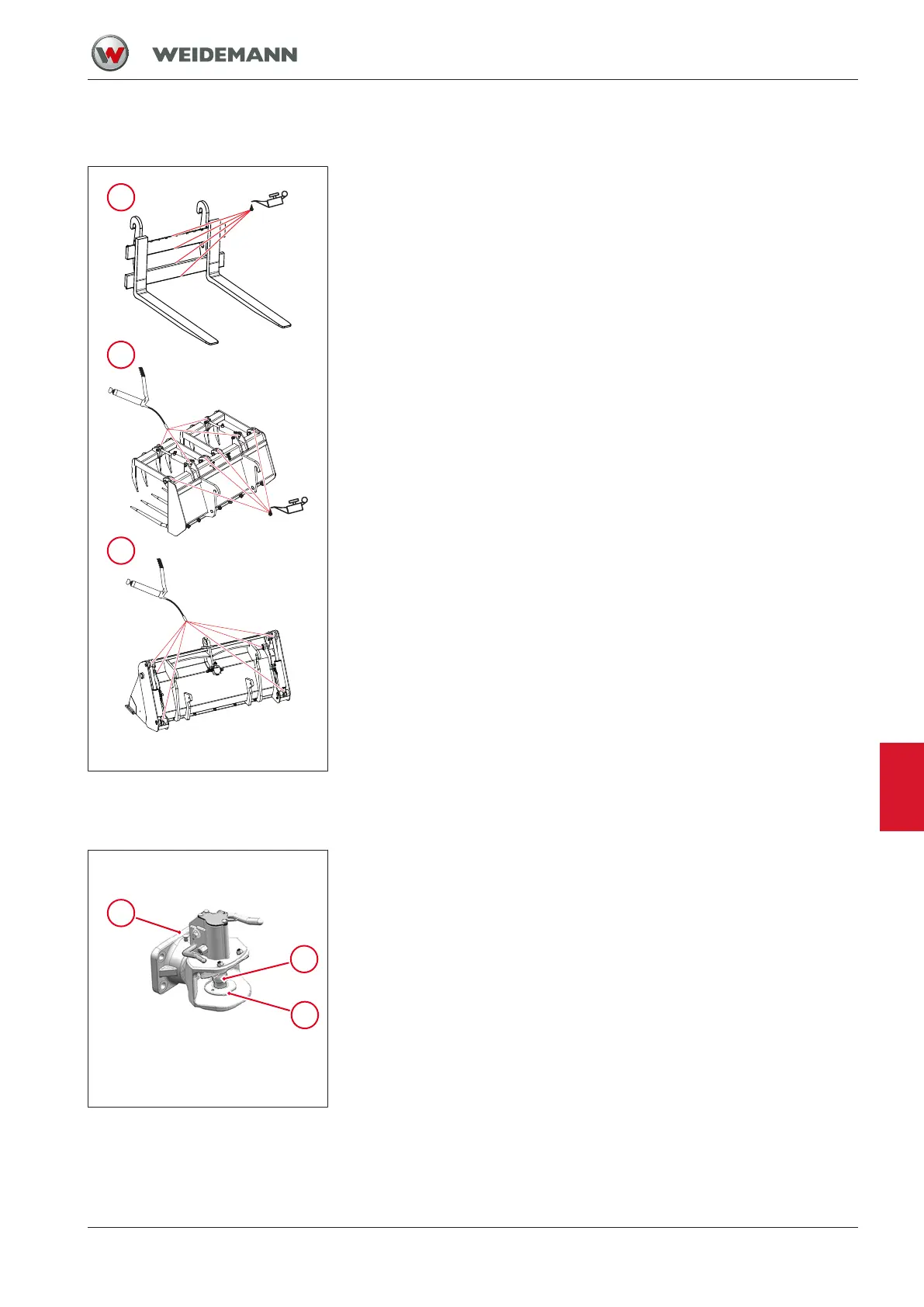

Fig.192: Lubrication points of the at-

tachments

1 Pallet fork

2 Fork-and-grab attachment

3 4-in-1 bucket

Correct maintenance and service is absolutely necessary for smooth and

continuous operation, and for a long service life of the attachments. The

lubrication, maintenance and care instructions in the corresponding oper-

ator’s manual for the attachments must be observed.

Clean attachments after use and check for damage. Have any damage

repaired by an authorized service center. Do not work with damaged at-

tachments.

Grease all lubrication points on the attachment weekly or every 20 oper-

ating hours with water-resistant multi-purpose grease. Lubricate all other

moving parts with an oil can.

9.7.4

Greasing the trailer coupling

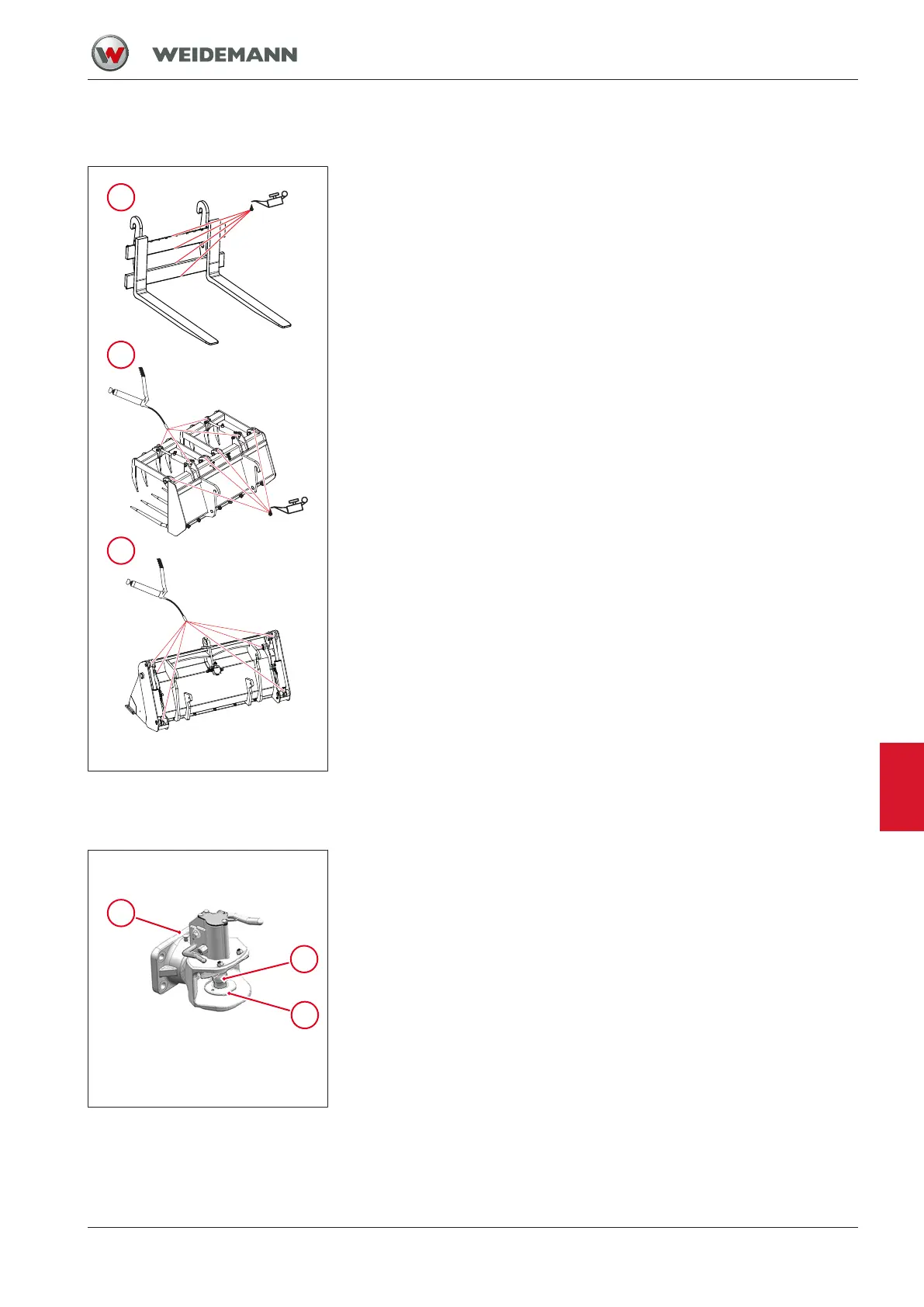

Fig.193: Greasing the trailer coup-

ling

In order to ensure the correct function of the trailer coupling, coupling pin

1 must be closed before cleaning with a high-pressure cleaner.

1. Close the trailer coupling.

2. After cleaning, lubricate coupling pin 1 and base ring 2 with tough,

water-resistant multi-purpose grease.

3. Grease the grease nipple 3 on the swivel joint.

9

Loading...

Loading...