CYLINDER

HEAD

SERVICE

Partial

Reassembly

1. Press in the valve guides to the specified height. (For the

installation procedure, see

Valve Guide.)

2. Install the valve stem seals securely on the valve guide.

3.

Apply oil to the valve stems and insert them into the

valve guides. Install the springs, retainers and retainer

locks in that order.

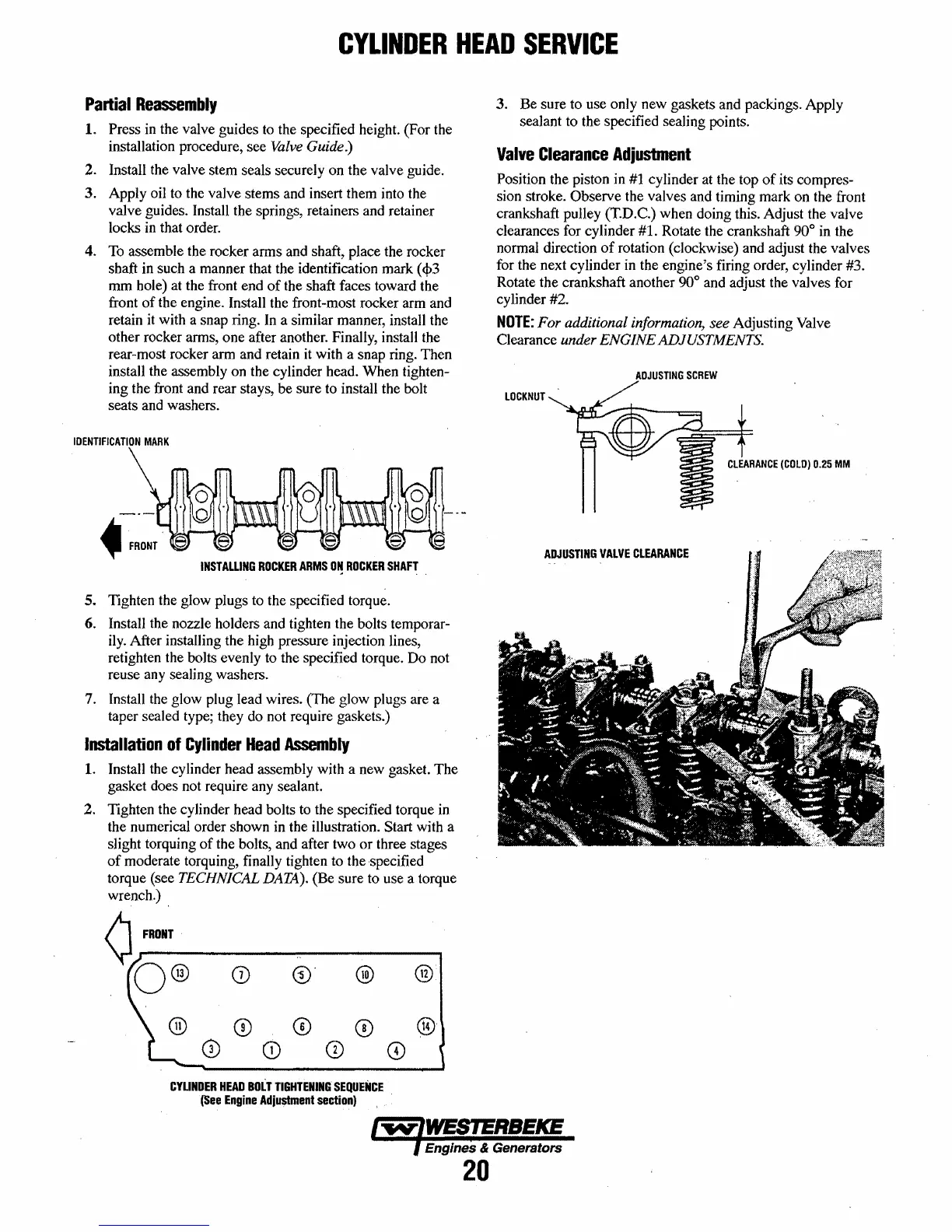

4. To assemble the rocker arms and shaft, place the rocker

shaft in such a manner that the identification mark

(4)3

mm hole) at the front end

of

the shaft faces toward the

front

of

the engine. Install the front-most rocker arm and

retain it with a snap ring. In a similar manner, install the

other rocker arms, one after another. Finally, install the

rear-most rocker arm and retain it with a snap ring. Then

install the assembly on the cylinder head. When tighten-

ing the front and rear stays, be sure to install the bolt

seats and washers.

IDENTIFICATION

MARK

•

FRONT·

INSTALLING

ROCKER

ARMS

O~

ROCKER

SHAFT

S. Tighten the glow plugs to the specified torque.

6. Install the nozzle holders and tighten the bolts temporar-

ily. After installing the high pressure injection lines,

retighten the bolts evenly to the specified torque. Do not

reuse any sealing washers.

7. Install the glow plug lead wires. (The glow plugs are a

taper sealed type; they do not require gaskets.)

Installation

of

Cylinder

Head

Assembly

1.

Install the cylinder head assembly with a new gasket.

The

gasket does not require any sealant.

2. Tighten the cylinder head bolts to the specified torque in

the numerical order shown in the illustration. Start with a

slight torquing

of

the bolts, and after two

or

three stages

of

moderate torquing, finally tighten to the ,specified

torque (see

TECHNICAL DA1A). (Be sure to use a torque

wrench.)

,

<:J

~F_RO_N_T

____________

~

______________

~

,O®

CD

(~y

@ ®

®

CYLINDER

HEAD

BOLT

TIGHTENING

SEQUENCE

(See

Engine

Adjustment

section)

3.

Be

sure to use only new gaskets and packings. Apply

sealant to the specified sealing points.

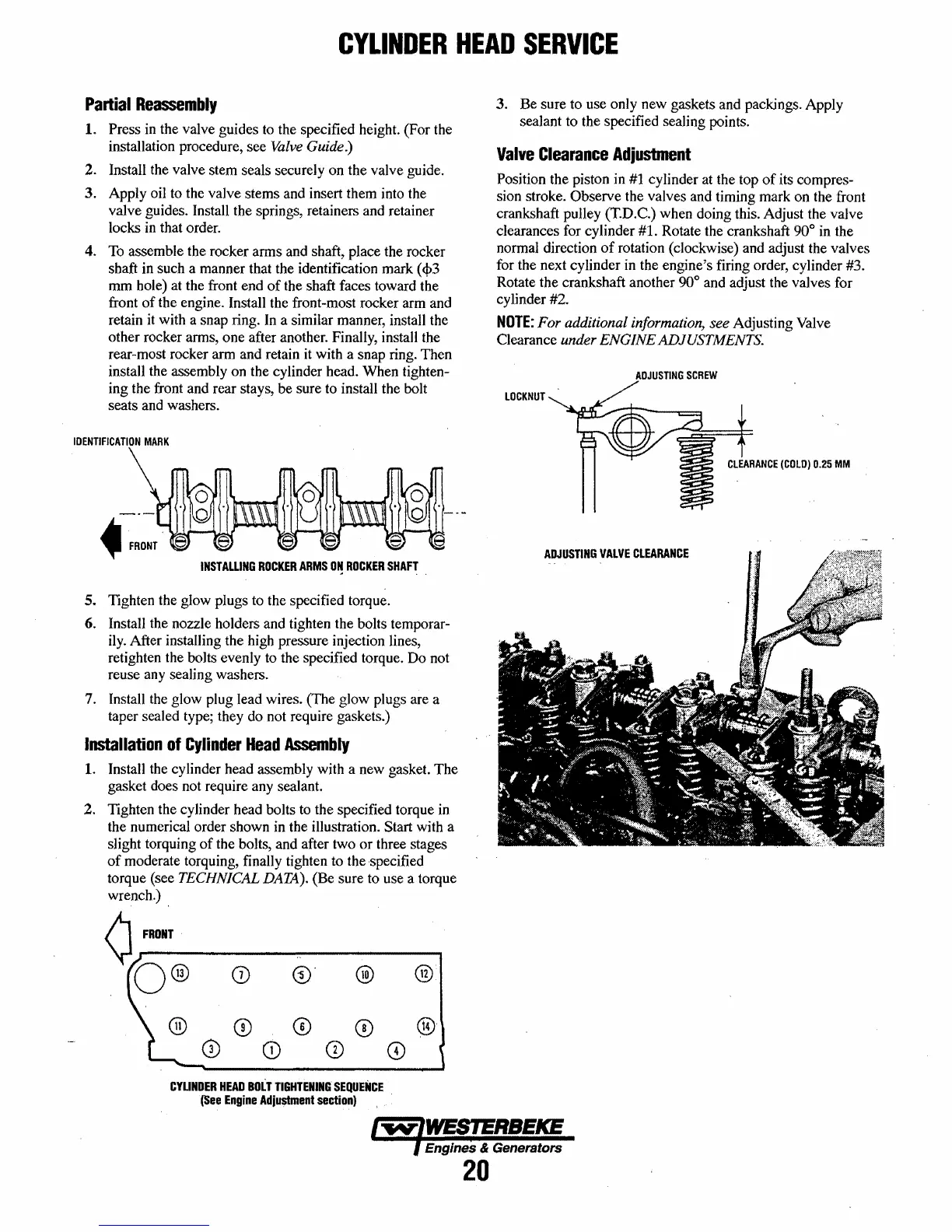

Valve

Clearance

Adjusbnent

Position the piston in

#1

cylinder at the top

of

its compres-

sion stroke. Observe the valves and timing mark on the front

crankshaft pulley

(T.D.C.) when doing this. Adjust the valve

clearances for cylinder

#1. Rotate the crankshaft 90° in the

normal direction

of

rotation (clockwise) and adjust the valves

for the next cylinder in the engine's firing order, cylinder #3.

Rotate the crankshaft another

90° and adjust the valves for

cy linder #2.

NOTE:

For additional information, see Adjusting Valve

Clearance

under ENGINE

AD]

USTMENTS.

ADJUSTING

SCREW

LOCKNUT

CLEARANCE

(COLD)

0.25

MM

ADJUSTING

VALVE

CLEARANCE

Engines & Generators

20

Loading...

Loading...