ENGINE

ADJUSTMENTS

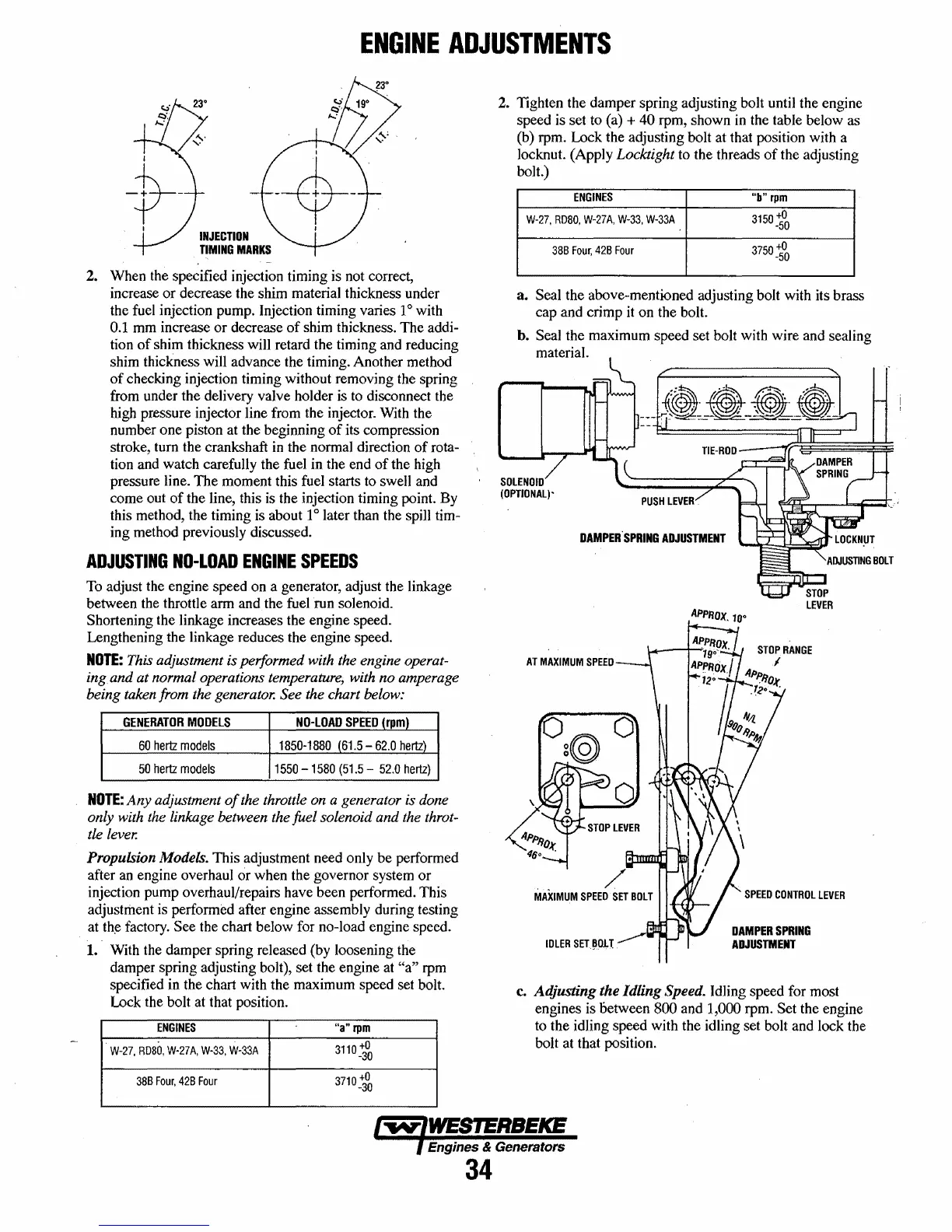

INJECTION

TIMING

MARKS

2. When the specified injection timing is not correct,

increase or decrease the shim material thickness under

the fuel injection pump. Injection timing varies

1°

with

0.1 mm increase or decrease

of

shim thickness. The addi-

tion

of

shim thickness will retard the timing and reducing

shim

thickness will advance the timing. Another method

of

checking injection timing without removing the spring

from under the delivery valve holder is

to

disconnect the

high pressure injector line from the injector. With the

number one piston at the beginning

of

its compression

stroke, tum the crankshaft

in

the normal direction

of

rota-

tion and watch carefully the fuel in the end

of

the high

pressure line. The moment this fuel starts to swell and

come out

of

the line, this

is

the injection timing point. By

this method, the timing is about 1

0

later than the spill tim-

ing method previously discussed.

ADJUSTING

NO-LOAD

ENGINE

SPEEDS

To

adjust the engine speed on a generator, adjust the linkage

between the throttle arm and the fuel run solenoid.

Shortening the linkage increases the engine speed.

Lengthening the linkage reduces the engine speed.

NOTE:

This adjustment is performed with the engine operat-

ing

and at normal operations temperature, with no amperage

being taken from the generator. See the chart below:

GENERATOR

MODElS

NO-LOAD

SPEED

(rpm)

60

hertz

models

1850-1880

(61.5

-

62.0

hertz)

50

hertz

models

1550

-1580

(51.5

52.0

hertz)

NOTE:

Any

adjustment

of

the throttle on a generator is done

only with the linkage between the fuel solenoid and the

throt-

tle

lever.

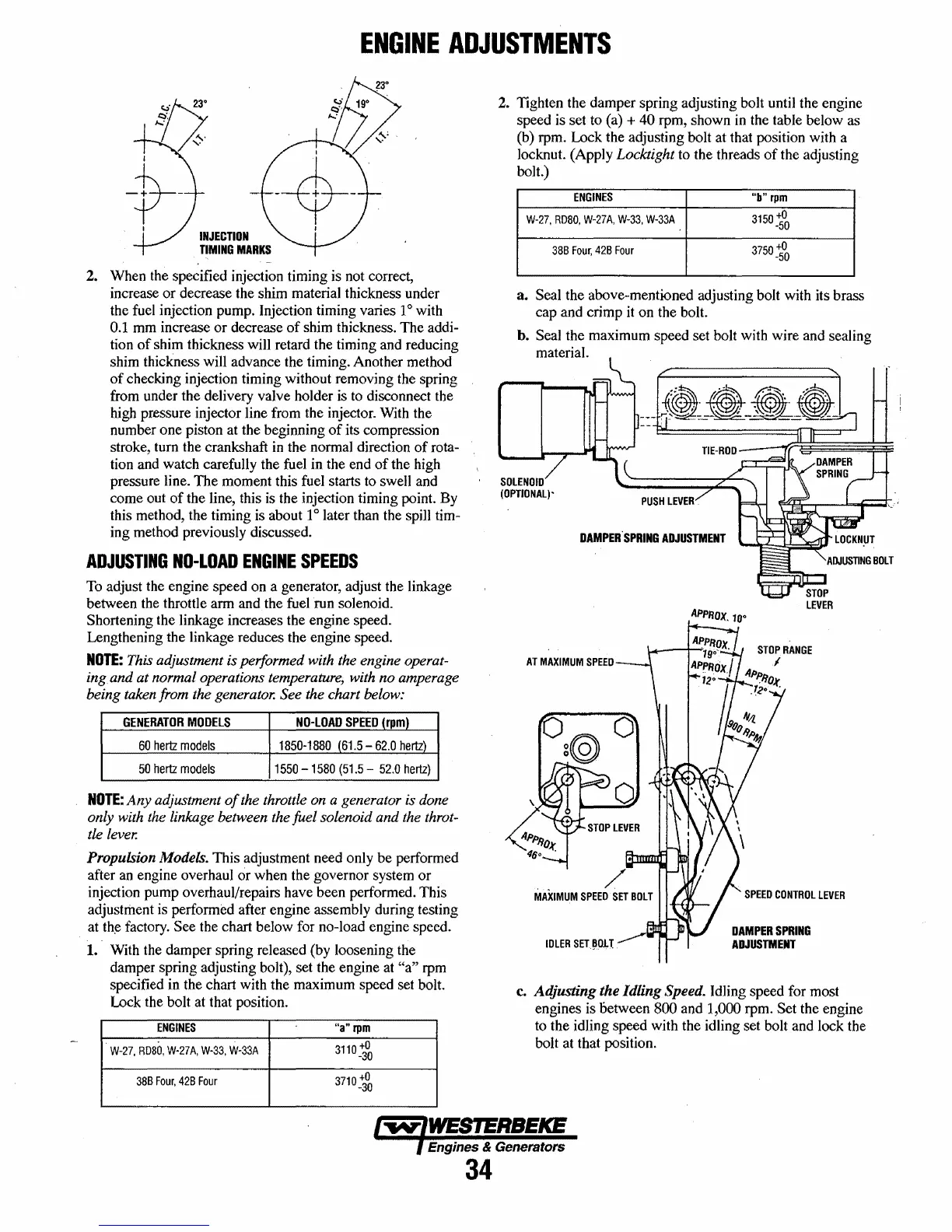

Propulsion Models. This adjustment need only be performed

after

an

engine overhaul

cir

when the governor system

or

injection pump overhaul/repairs have been performed. This

adjustment is performed after engine assembly during testing

at

th~

factory. See the chart below for no-load engine speed.

1.· With the damper spring released (by loosening the

damper spring adjusting bolt), set the engine at

"a"

rpm

specified in the chart with the maximum speed set bolt.

lock

the bolt at that position.

ENGINES

"a"

rpm

W-27,

RD80,

W·27A,

W-33,

W-33A

3110

+0

-30

38B

Four,

428

Four

3710

+0

-30

2. Tighten the damper spring adjusting bolt

unti1

the engine

speed is set to (a)

+ 40 rpm, shown

in

the table below as

(b) rpm. Lock the adjusting bolt at that position with a

locknut. (Apply Locktight to the threads

of

the adjusting

bolt.)

ENGINES

"b"

rpm

W·27,

RD80,

W-27A,

W-33,

W-33A

3150

+0

·50

38B

Four,

42B

Four

3750

+0

-50

a.

Seal the above-mentioned adjusting bolt with its brass

cap and crimp

it

on the bolt.

h.

Seal the maximum speed set bolt with wire and sealing

material.

SOLENOID

(OPTIONAL)-

DAMPER·SPRING

ADJUSTMENT

APpF/OX.1O"

STOP

LEVER

STOP

RANGE

SPEED

CONTROL

LEVER

DAMPER

SPRING

ADJUSTMENT

c.

Adjusting the Idling Speed. Idling speed for most

engines is

oetween 800 and 1,000 rpm. Set the engine

to the idling speed with the idling set bolt and lock the

bolt at that position.

Engines & Generators

34

Loading...

Loading...