CYLINDER

BLOCK

CONSTRUCTION

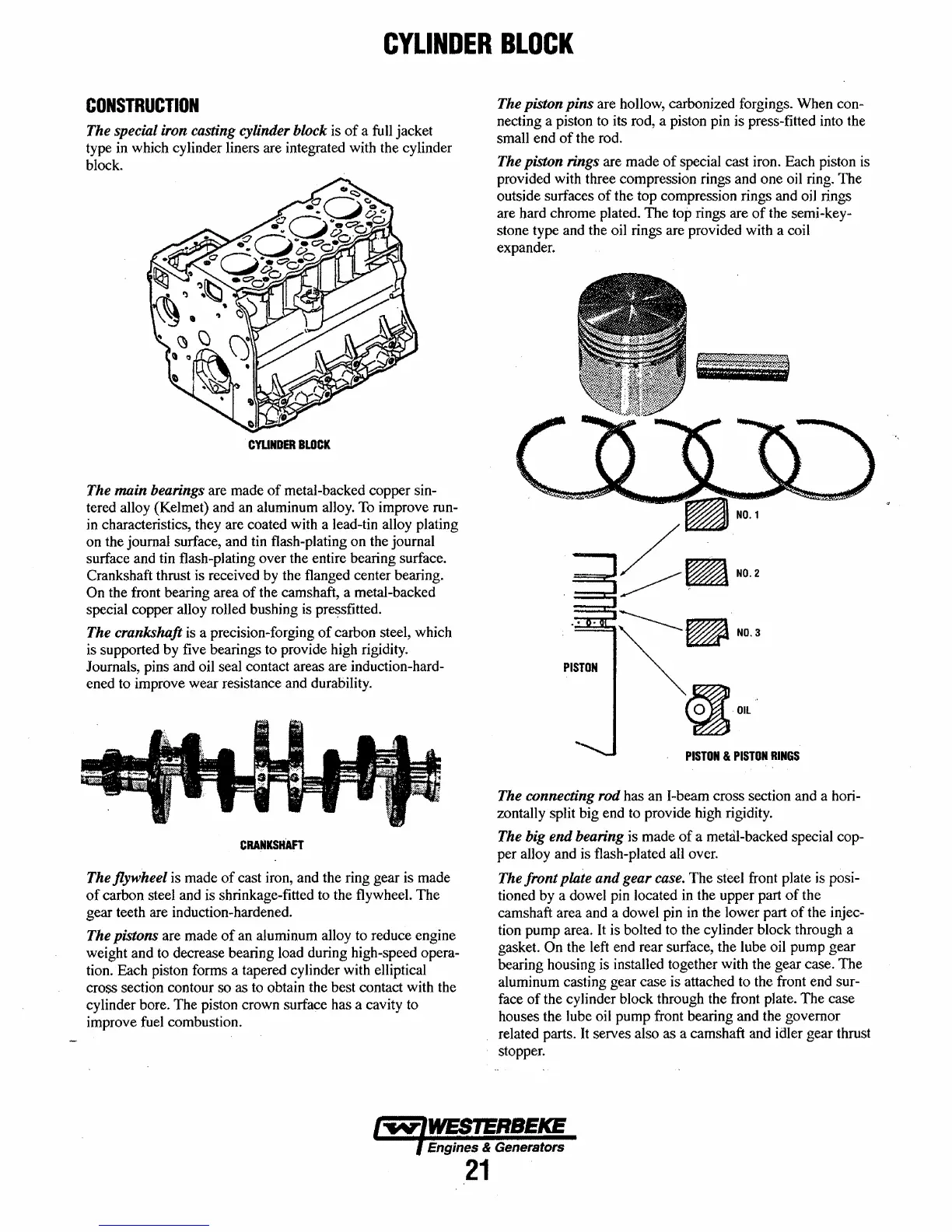

The special iron casting cylinder block is

of

a full jacket

type in which cylinder liners are integrated with the cylinder

block.

CYUNDER

BLOCK

The main bearings are made

of

metal-backed copper sin-

tered alloy (Kelmet) and an aluminum alloy. To improve run-

in characteristics, they are coated with a lead-tin alloy plating

on the journal surface, and tin flash-plating on the journal

surface and tin

flash~plating

over the entire bearing surface.

Crankshaft thrust is received by the flanged center bearing.

On the front bearing area

of

the camshaft, a metal-backed

special copper alloy rolled bushing is

pre!?sfitted.

The crankshaft is a precision-forging

of

carbon steel, which

is supported by five bearings to provide high rigidity.

Journals, pins and oil seal contact areas are induction-hard-

ened to improve wear resistance and durability.

The flywheel is made

of

cast iron, and the ring gear is made

of

carbon steel and is shrinkage-fitted to the flywheel. The

gear teeth are induction-hardened.

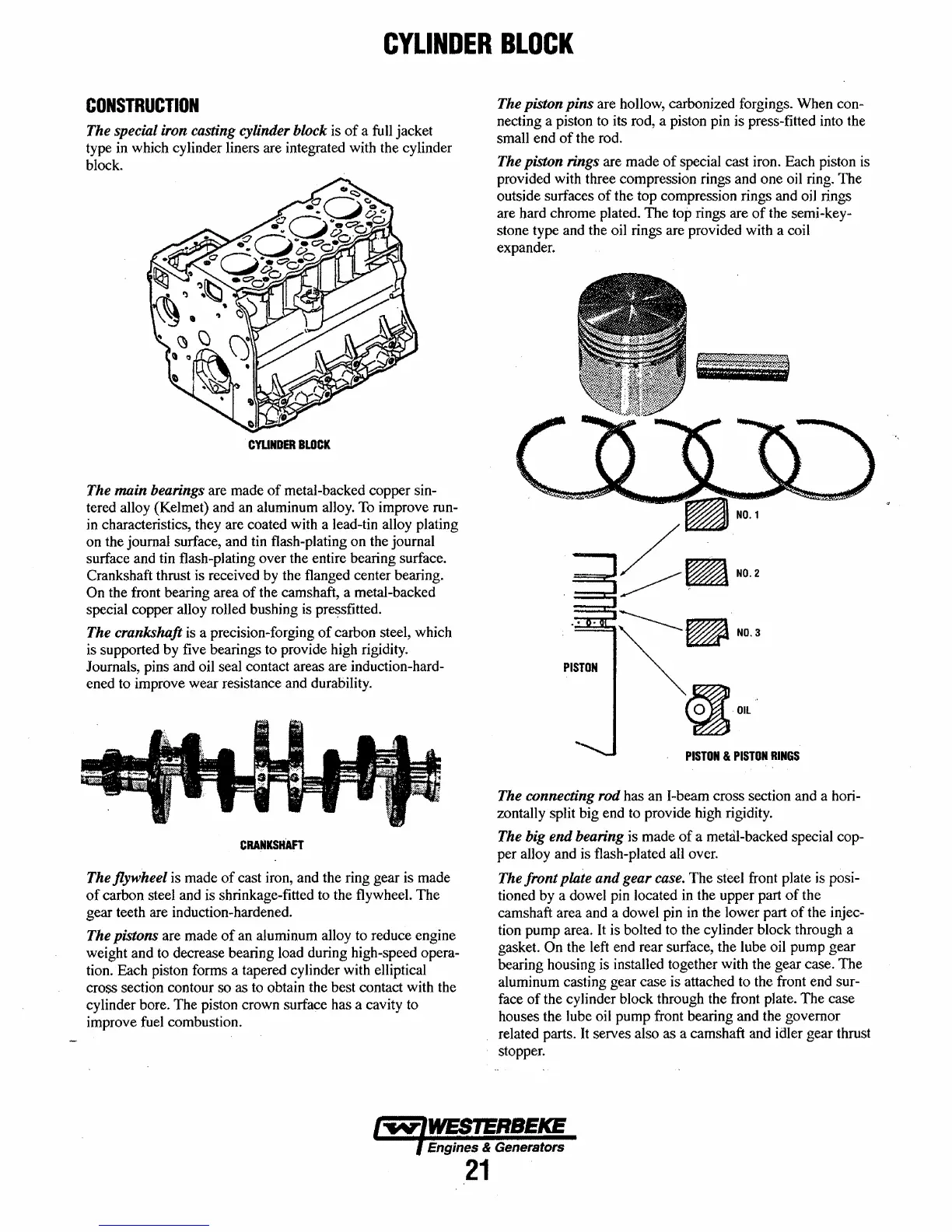

The pistons are made

of

an aluminum alloy to reduce engine

weight and to decrease bearing load during high-speed opera-

tion. Each piston forms a tapered cylinder with elliptical

cross section contour so as to obtain the best contact with the

cylinder bore. The piston crown surface has a cavity to

improve fuel combustion.

The piston pins are hollow, carbonized forgings. When con-

necting a piston to its rod, a piston pin is press-fitted into the

small end

of

the rod.

The piston rings are made

of

special cast iron. Each piston is

provided with three compression rings and one oil ring. The

outside surfaces

of

the top compression rings and oil rings

are hard chrome plated. The top rings are

of

the semi-key-

stone type and the oil rings are provided with a coil

expander.

PISTON

&

PISTON

RINGS

The connecting rod has an I-beam cross section and a hori-

zontally split big end to provide high rigidity.

The big end bearing is made

of

a metal-backed special cop-

per alloy and is flash-plated all over.

The front piate

and

gear case. The steel front plate is posi-

tioned by a dowel pin located

in

the upper part

of

the

camshaft area and a dowel pin

in

the lower part

of

the injec-

tion pump area.

It is bolted to the cylinder block through a

gasket.

On the left end rear surface, the lube oil pump gear

bearing housing is installed together with the gear case. The

aluminum casting gear case is attached to the front end sur-

face

of

the cylinder block through the front plate. The case

houses the lube oil pump front bearing and the governor

related parts.

It serves also as a camshaft and idler gear thrust

stopper.

Engines & Generators

21

Loading...

Loading...