FUEL

SYSTEM

SERVICE

Injector

1.

Disconnect the return pipe from the nozzle holder upper

nipple.

2. Disconnect the

fuel injection pipe from the nozzle holder.

3. Loosen the nozzle holder attaching bolts and remove the

holder assembly.

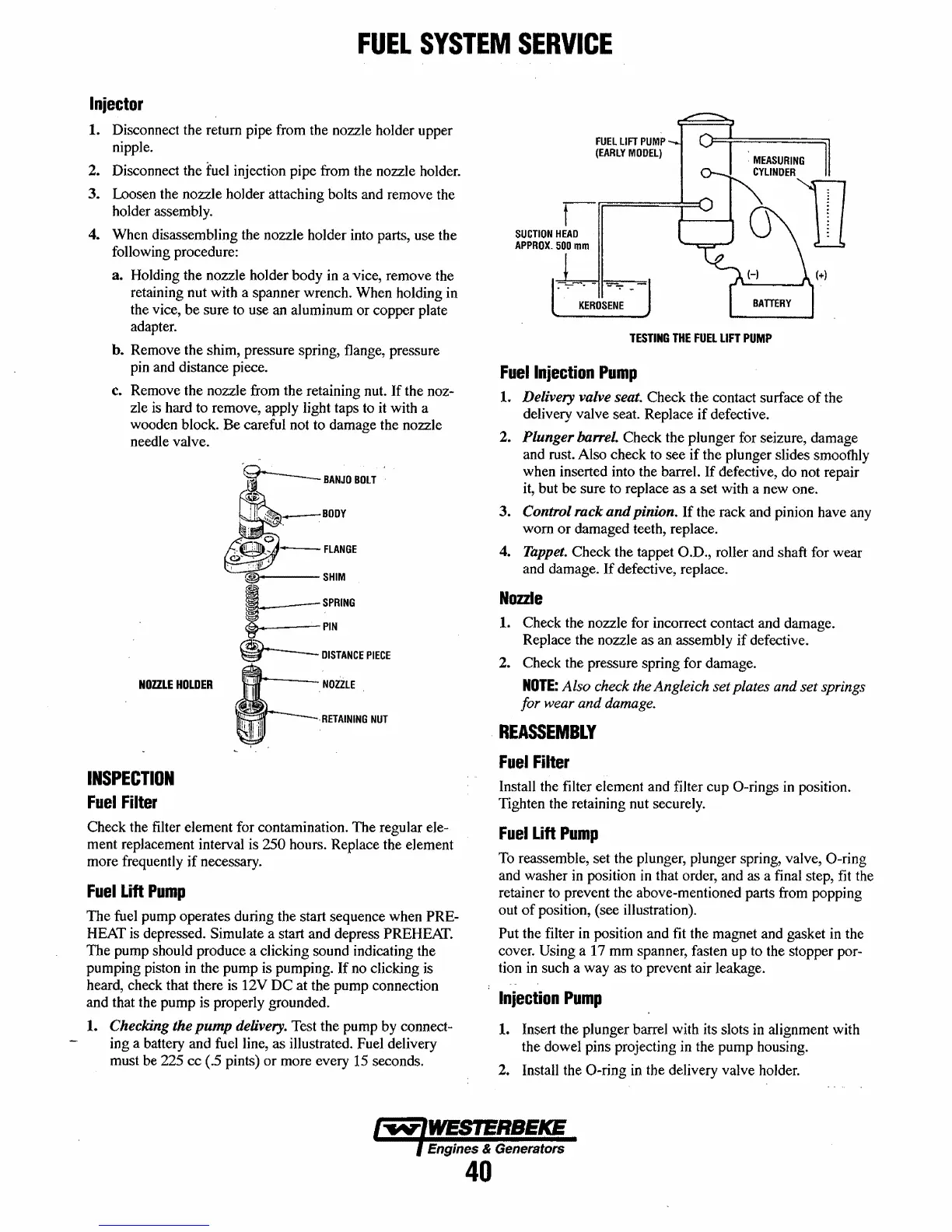

4. When disassembling the nozzle holder into parts, use the

following procedure:

8.

Holding the nozzle holder body in a vice, remove the

retaining nut with a spanner wrench. When holding

in

the vice, be sure to use an aluminum or copper plate

adapter.

h.

Remove the shim, pressure spring, flange, pressure

pin and distance piece.

c. Remove the nozzle from the retaining nut. If the noz-

zle

is

hard to remove, apply light taps to

it

with a

wooden block. Be careful not to damage the nozzle

needle valve.

NOZZLE

HOLDER

INSPECTION

Fuel

Filter

'r--SANJOBOlT'

~

! I

',;;,.~,

_,

BOOY

t

1

r

,(,)

•

NOZZLE

,

.

RETAINING

NUT

Check the filter element for contamination. The regular ele-

ment replacement interval is

250 hours. Replace the element

more frequently

if

necessary.

Fuel

Lift

Pump

The fuel pump operates during the start sequence when PRE-

HEAT is depressed. Simulate a start and depress PREHEAT.

The pump should produce a clicking sound indicating the

pumping piston in the pump is pumping. If no clicking is

heard, check that there is 12V DC at the pump connection

and that the pump is properly grounded.

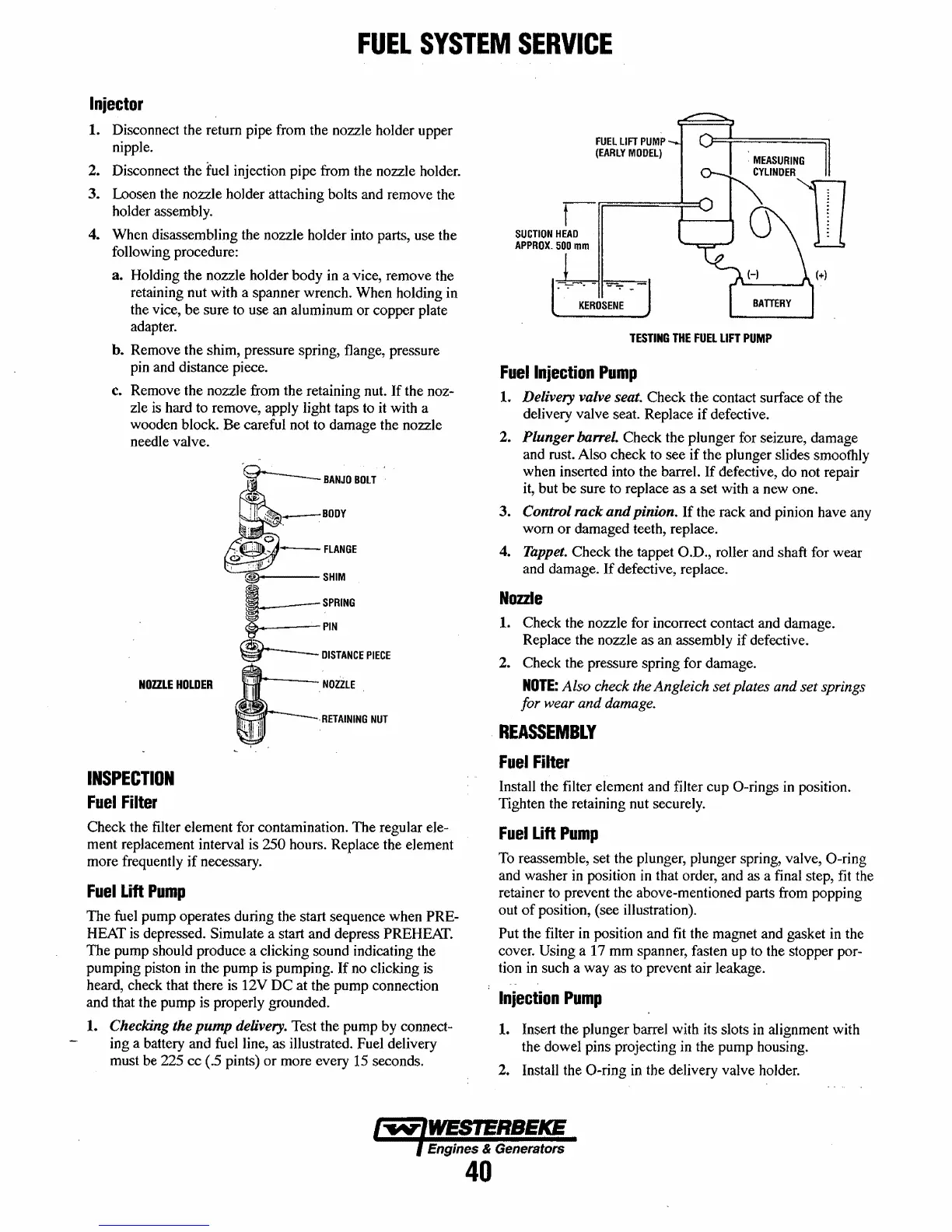

1.

Checking the pump delivery. Test the pump by connect-

ing a battery and fuel line, as illustrated. Fuel delivery

must be 225 cc (.5 pints) or more every 15 seconds.

TESTING

THE

FUEL

LIFT

PUMP

Fuel

Injection

Pump

1.

Delivery valve seat. Check the contact surface

of

the

delivery valve seat. Replace

if

defective.

2.

Plunger barrel. Check the plunger for seizure, damage

and rust. Also check to see

if

the plunger slides smoofhly

when inserted into the barrel. If defective, do not repair

it, but be sure to replace as a set with a new one.

3. Control rack and pinion.

If

the rack and pinion have any

worn

or

damaged teeth, replace.

4.

Tappet.

Check the tappet O.D., roller and shaft for wear

and damage. If defective, replace.

Nozzle

1.

Check the nozzle for incorrect contact and damage.

Replace the nozzle as an assembly

if

defective.

2. Check the pressure spring for damage.

NOTE:

Also check

the

Angleich set plates and set springs

for wear and damage .

REASSEMBLY

Fuel

Filter

Install the filter element and filter cup O-rings

in

position.

Tighten the retaining nut securely.

Fuel

Lift

Pump

To

reassemble, set the plunger, plunger spring, valve, O-ring

and washer in position

in

that order, and as a final step, fit the

retainer to prevent the above-mentioned parts from popping

out

of

position, (see illustration).

Put the filter

in

position and fit the magnet and gasket in the

cover.

Using a 17 mm spanner, fasten up to the stopper por-

tion

in

such a way as to prevent air leakage.

Injection

Pump

1. Insert the plunger barrel with its slots in alignment with

the dowel pins projecting

in

the pump housing.

2. Install the O-ring

in

the delivery valve holder.

Engines & Generators

40

Loading...

Loading...