FRESH

WATER

COOLING

SERVICE

DISASSEMBLY

1.

Drain the cooling water. A drain plug for draining the

engine block is located on the side

of

the engine block

just right

of

the lube oil

fi1ter.

A drain plug for draining

the heat exchanger is located on the heat exchanger.

2. Disconnect the water hose from the pump.

NOTE:

Generator models are equipped with belt guards

that will need to be removed.

3. Remove the pump drive belt.

4. Disconnect the bypass hose when equipped.

5. Remove the water pump assembly.

6.

If necessary, remove the water pump adapter when

equipped.

7.

On an engine with a thermostat, remove the water outlet

fitting bolts

in

the front

of

the cylinder head and remove

the thermostat.

INSPECTION

Water

Pump

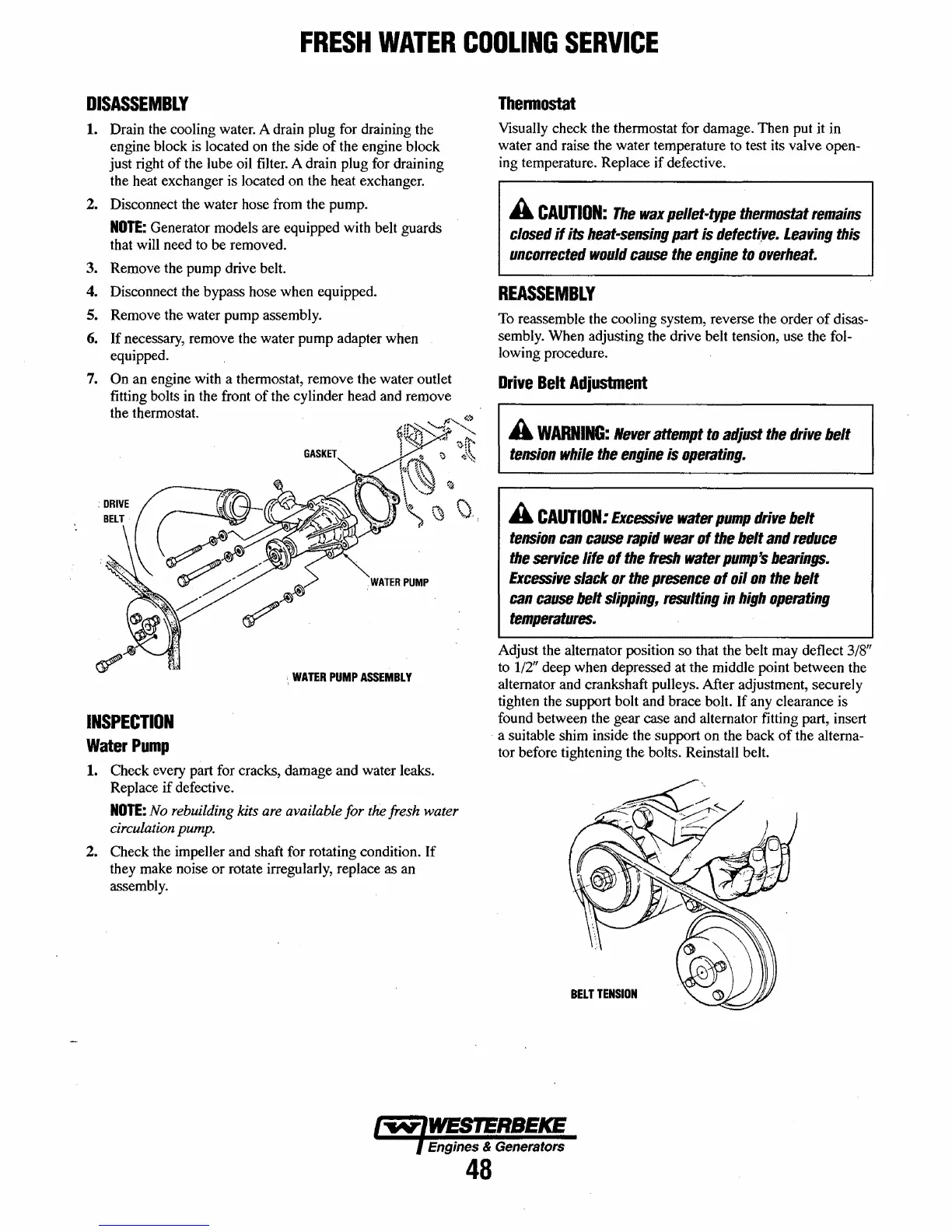

WATER

PUMP

ASSEMBLY

1. Check every part for cracks, damage and water leaks.

Replace

if

defective.

NOTE:

No rebuilding kits are available for the fresh water

circulation pump.

2. Check the impeller and shaft for rotating condition. If

they make noise or rotate irregularly, replace as an

assembly.

Thermostat

Visually check the thermostat for damage. Then put it in

water and raise the water temperature to test its valve open-

ing temperature. Replace if defective.

A

CAUTION:

The

wax

pellet-type

thermostat

remains

closed

if

its

heat-sensing

part

is

defect(ve.

Leaving

this

uncorrected

would

cause

the

engine

to

overheat.

REASSEMBLY

To

reassemble the cooling system, reverse the order

of

disas-

sembly. When adjusting the drive belt tension, use the fol-

lowing procedure.

Drive

Belt

Adjusbnent

A

WARNING:

Never

attempt

to

adjust

the

drive

belt

tension

while

the

engine

is

operating.

A

CAUTION:

Excessive

water

pump

drive

belt

tension

can

cause

rapid

wear

of

the

belt

and

reduce

the

service

life of

the

fresh

water

pump's

bearings.

Excessive

slack

or

the

presence

of oil

on

the

belt

can

cause

belt

slipping,

resulting

in

high

operating

temperatures.

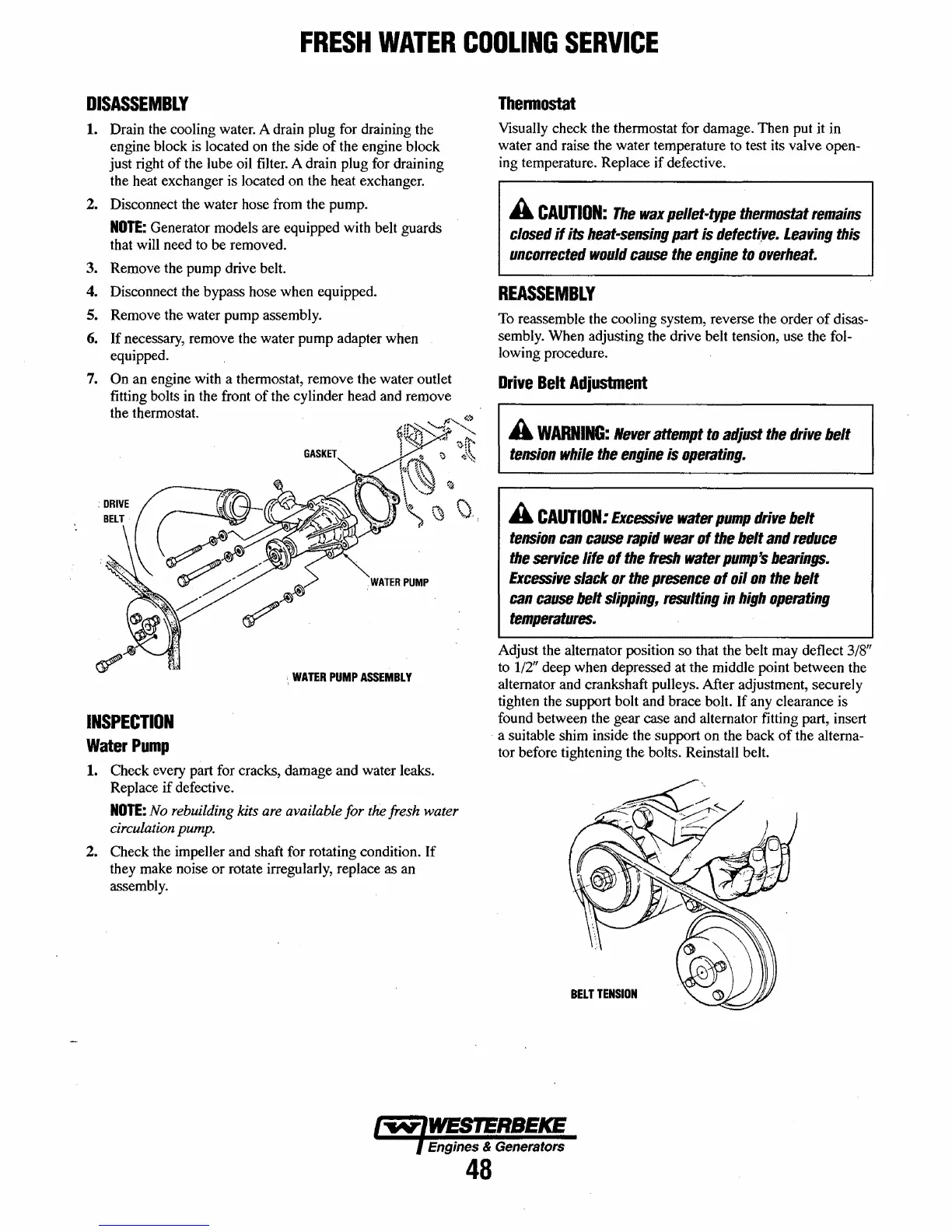

Adjust the alternator position so that the belt may deflect 3/8"

to 1/2" deep when depressed at the middle point between the

alternator and crankshaft pulleys. After adjustment, securely

tighten the support bolt and brace bolt. If any clearance is

found between the gear case and alternator fitting part, insert

a suitable shim inside the support on the back

of

the alterna-

tor before tightening the bolts. Reinstall belt.

BELT

TENSION

Engines & Generators

48

Loading...

Loading...