LUBRICATION

SYSTEM

SERVICE

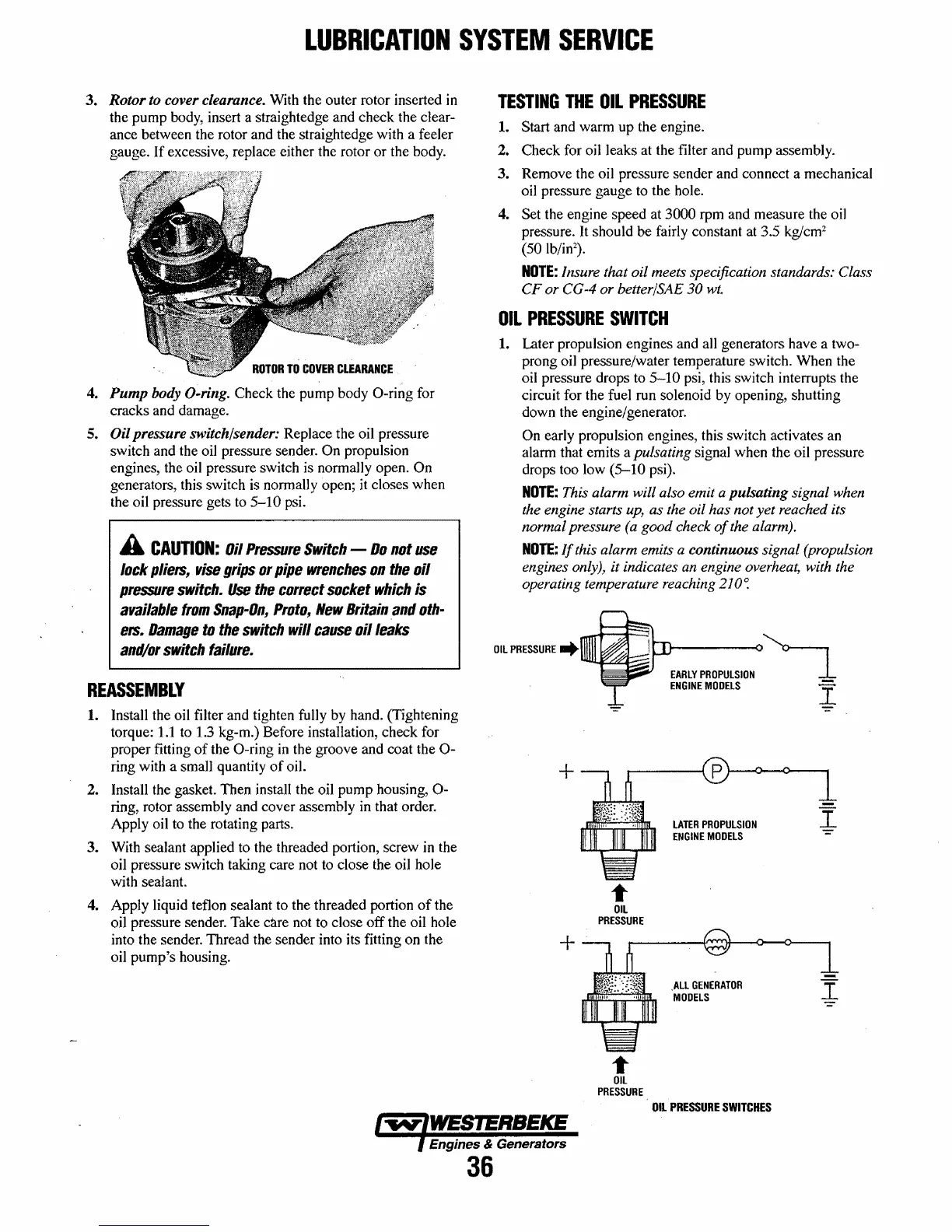

3.

Rotor

to cover clearance. With the outer rotor inserted

in

the pump body, insert a straightedge and check the clear-

ance between the rotor and the straightedge with a feeler

gauge. If excessive, replace either the rotor or the body.

ROTOR

TO

COVER

CLEARANCE

4.

Pump

body O-ring. Check the pump body O-ring for

cracks and damage.

S.

Oil

pressure switch/sender: Replace the oil pressure

switch and the oil pressure sender.

On propulsion

engines, the oil pressure switch is norma]]y open.

On

generators, this switch is normally open;

it

closes when

the oil pressure gets to

5-10 psi.

A

CAUTION:

Oil

Pressure

Switch

-

Do

not

use

lock

pliers,

vise

grips

or

pipe

wrenches

on

the

oil

pressure

switch.

Use

the

correct

socket

which

is

available

from

Snap-On,

Proto,

New

Britain

and

oth-

ers.

Damage

to

the

switch

will

cause

oil

leaks

and/or

switch

failure.

REASSEMBLY

1. Install the oil filter and tighten fully by hand. (Tightening

torque:

1.1

to 1.3 kg-m.) Before installation, check for

proper fitting

of

the O-ring

in

the groove and coat the

0-

ring with a small quantity

of

oil.

2. Install the gasket. Then install the oil pump housing,

0-

ring, rotor assembly and cover assembly

in

that order.

Apply oil to the rotating parts.

3. With sealant applied to the threaded portion, screw in the

oil pressure switch taking care not

to

close the oil hole

with sealant.

4. Apply liquid teflon sealant to the threaded portion

of

the

oil pressure sender. Take

care not to close off the oil hole

into the sender. Thread the sender into its fitting on the

oil pump's housing.

TESTING

THE

OIL

PRESSURE

1.

Start and warm up the engine.

2. Check for

oilleaks

at the filter and pump assembly.

3. Remove the oil pressure sender and connect a mechanical

oil pressure gauge to the hole.

4.

Set the engine speed at 3000 rpm and measure the oil

pressure.

It

should be fairly constant at

3.5

kg/cm2

(50

Ib/in2).

NOTE:

Insure that

oil

meets specification standards: Class

CF

or

CG-4

or

better/SAE

30

wt.

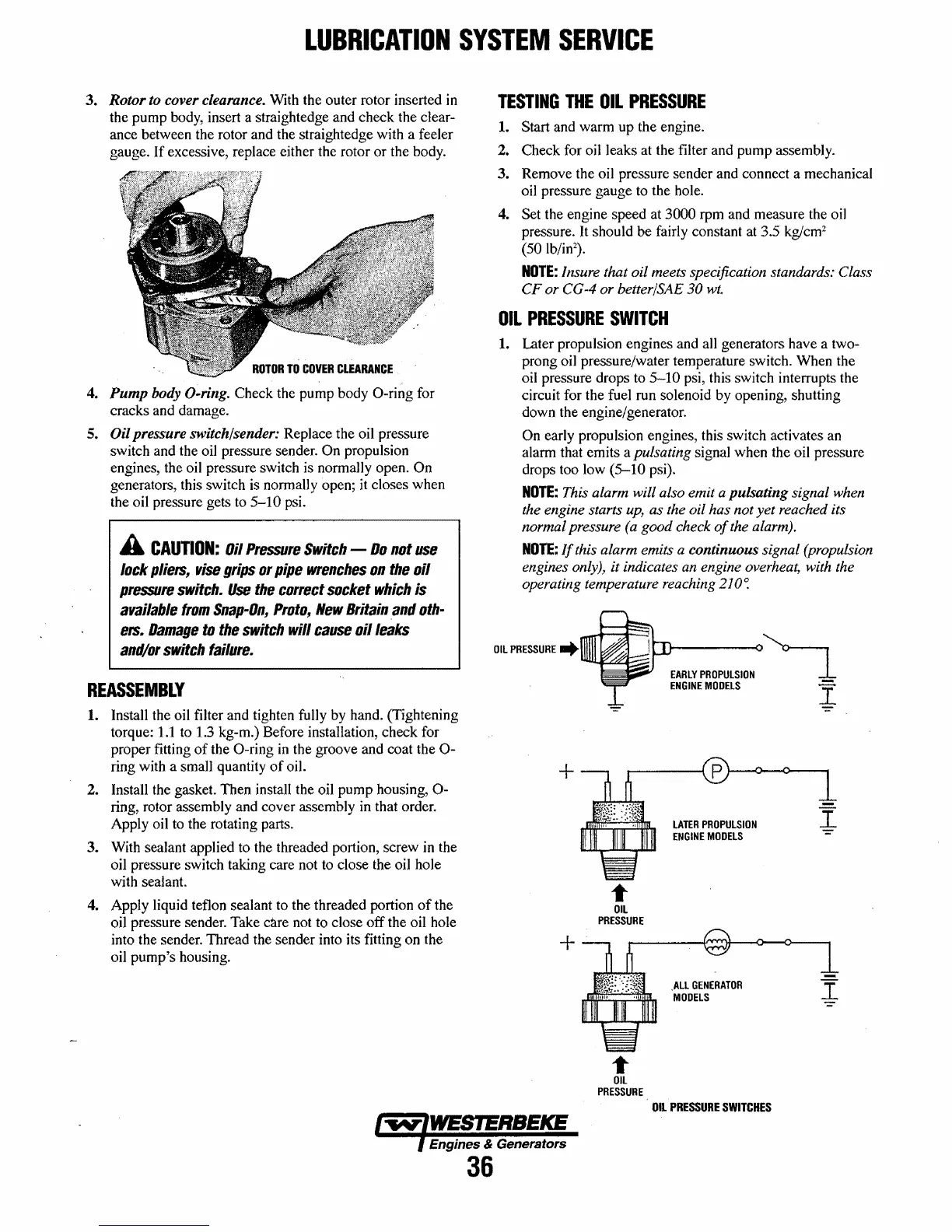

OIL

PRESSURE

SWITCH

1.

Later propulsion engines and all generators have a two-

prong oil pressure/water temperature switch. When the

oil pressure drops to

5-10 psi, this switch interrupts the

circuit for the fuel run solenoid by opening, shutting

down the engine/generator.

On early propulsion engines, this switch activates

an

alarm that emits a pulsating signal when the oil pressure

drops too low

(5-10 psi).

NOTE:

This alarm will also emit a

pulsating

signal when

the

engine starts up, as the oil

has

not

yet

reached its

normal pressure

(a

good

check

o/the

alarm).

NOTE:

If

this alarm emits a

continuous

signal (propulsion

engines

only),

it

indicates an engine overheat, with the

operating temperature reaching

210~

OIL

PRESSURE

....

+

+

t-

OIL

PRESSURE

t-

OIL

PRESSURE

'ARLY

PROPULSION

"1

ENGINE

MODELS

%

P

LATER

PROPULSION

~

ENGINE

MODELS

,ALL

GENERATOR

J

MODElS

.

OIL

PRESSURE

SWITCHES

Engines & Generators

36

Loading...

Loading...