CYLINDER

HEAD

CONSTRUCTION

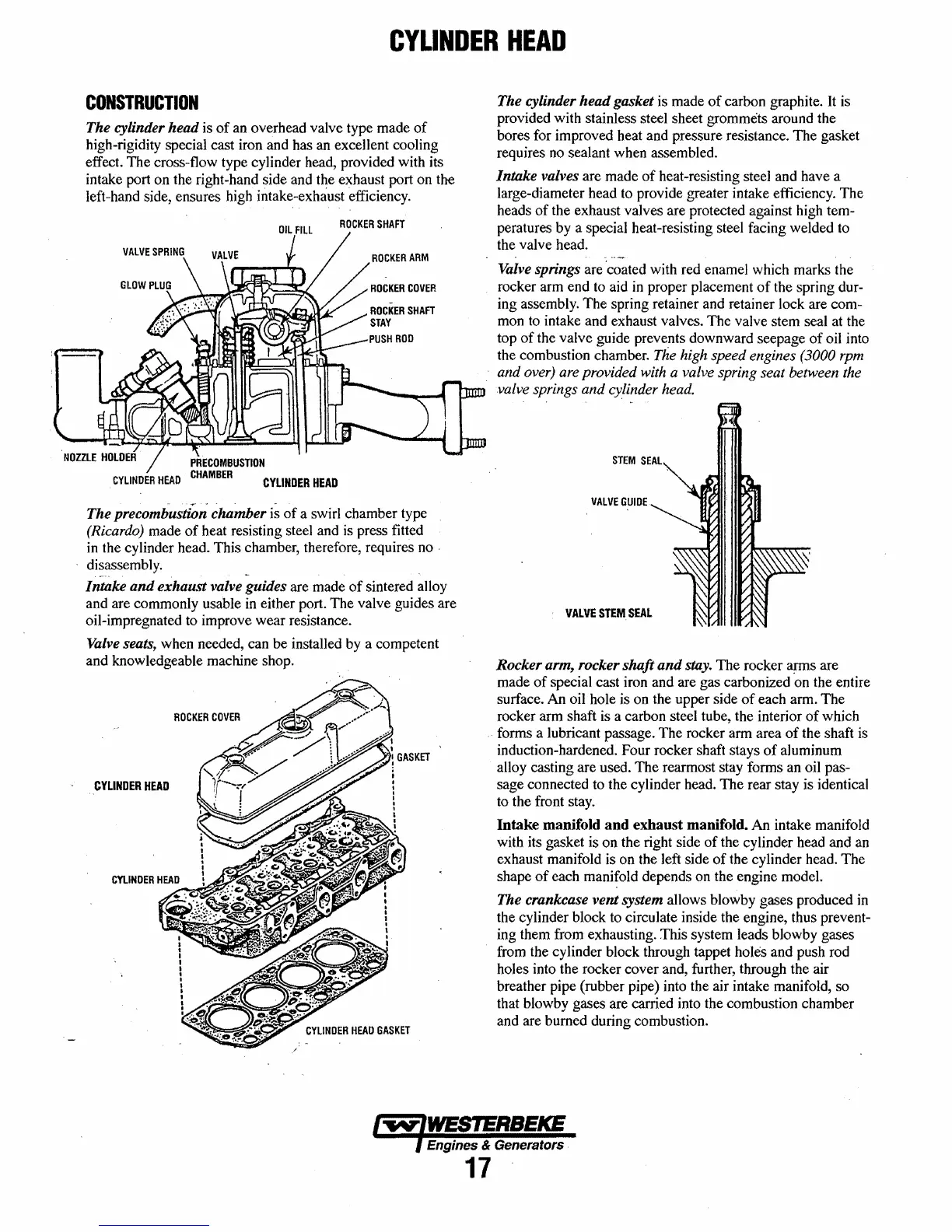

The

cylinder

head

is

of

an overhead valve type made

of

high-rigidity special cast iron and has an excel1ent cooling

effect.

The

cross-flow type cylinder head, provided with its

intake port on the right-hand side and

t~e

exhaust port on the

left-hand side, ensures high intake-exhaust efficiency.

ROCKER

SHAFT

CYLINDER

HEAD

The

precombustion

chamber

is

of

a swirl chamber type

(Ricardo) made

of

heat resisting steel and

is

press fitted

in the cylinder head. This chamber, therefore, requires no

'

disassembly.

Intake

and

exhaust

valve guides are made

of

sintered alloy

and are commonly usable in either port. The valve guides are

oil-impregnated to improve wear resistance.

Valve seats, when needed, can

be

installed by a competent

and knowledgeable machine shop.

ROCKER

COVER

CYLINDER

HEAD

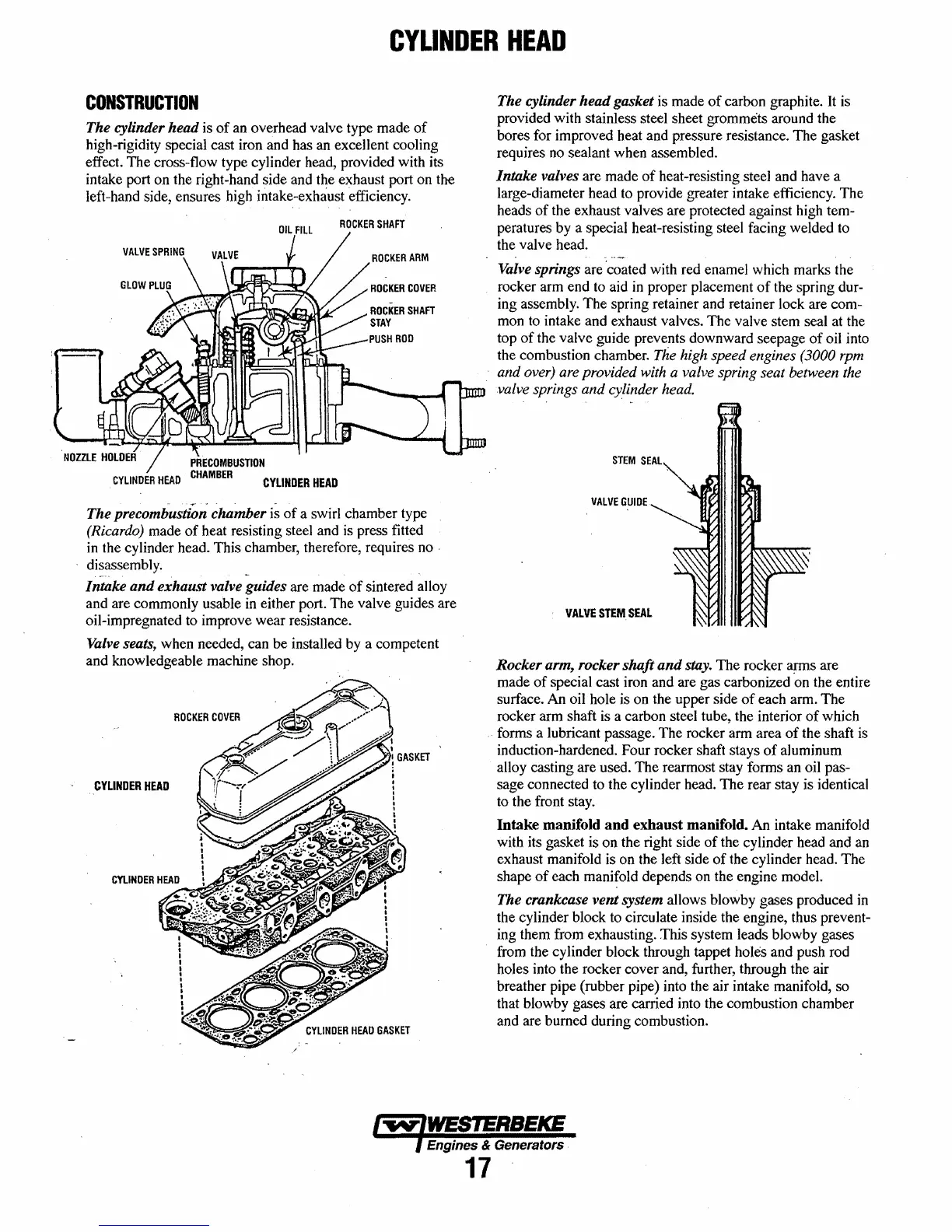

The cylinder

head

gasket is made

of

carbon graphite. It is

provided with stainless steel sheet

grommets around the

bores for improved heat and pressure resistance. The gasket

requires no sealant when assembled.

Intake

valves are made

of

heat-resisting steel and have a

large-diameter head to provide greater intake efficiency. The

heads

of

the exhaust valves are protected against high tem-

peratures by a special heat-resisting steel facing welded to

the valve head.

Valve springs are 'coated with red enamel which marks the

rocker arm end to aid in proper placement

of

the spring dur-

ing assembly.

The

spring retainer and retainer lock are com-

mon to intake and exhaust valves. The valve stem seal at the

top

of

the valve guide prevents downward seepage

of

oil into

the combustion chamber.

The high speed engines (3000 rpm

and

over) are provided with a valve spring seat between the

valve springs

and

cylinder head.

VALVE

GUIDE

VALVE

STEM.

SEAL

Rocker

arm, rocker

shaft

and

stay.

The

rocker arms are

made

of

special cast iron and are gas carbonized on the entire

surface. An oil hole is on the upper side

of

each arm.

The

rocker arm shaft is a carbon steel tube, the interior

of

which

forms a lubricant passage. The rocker arm area

of

the shaft is

induction-hardened. Four rocker shaft stays

of

aluminum

alloy casting are used.

The

rearmost stay forms an oil pas-

sage connected to the cylinder head.

The

rear stay is identical

to the front stay.

Intake manifold and exhaust manifold. An intake manifold

with its gasket is on the right side

of

the cylinder head and an

exhaust manifold is on the left side

of

the cylinder head. The

shape

of

each

mani~old

depends on the engine model.

The crankcase

vent

system allows blowby gases produced in

the cylinder block to circulate inside the engine, thus prevent-

ing them from exhausting. This system leads blowby gases

from the cylinder block through tappet

holes and push rod

holes into the rocker cover and, further, through the air

breather pipe (rubber pipe) into the air intake manifold, so

that blowby gases are carried into the combustion chamber

and are burned during combustion.

Engines & Generators

17

Loading...

Loading...