WMD

GENERATOR

TROUBLESHOOTING

2. Check for a short

or

open

in

the rotating armature or in

the stationary field coils.

ROTATING

ARMATURE

(RESISTANCE

VALUES)

1

1

ohm

or

less

between

slip

rings

WMD

11.0

and

12.5

KW

(1

&3)

and

(2&4)

NOTE:

4-wire units: there should

be

no

continuity found

between slip rings (1&2), (2&3) and (3&4).

If

continuity

is found, an internal short exists between these windings

and the armature should

be

replaced.

NOTE:

There should be no continuity found between any

of

the slip rings and the armature's central steel shaft.

If

continuity is found, the windings are shorted to the shaft

and the armature should be replaced.

Rotating armature slip rings are numbered from inboard

of

the generator flywheel end outward to the rear support

bearing. When referring to 2, 3 and 4-wire units, these

are the number

of

generator output leads being connected

to the load. You will find on the 11.0 and 12.5 KW units

that there are

8 leads coming from the brush rig and they

are in pairs that are combined for a total

of

4 output

leads. The number

of

wires can also

be

related to the

number

of

slip rings on the rotating armature.

REPLACEMENT

OF

FIELD

COIL(S)

1.

Field coils are connected in series and the resistance

value given

in

this text is the total

of

the four field coils.

To determine the resistance value

of

one, divide by four.

Each field coil has a mounting position on the generator

housing and cannot

be

interchanged with another field

coil.

When installing a replacement field coil(s), the installer

must ensure that the coil is correct for the mounting posi-

tion in the housing and will have the correct polarity

when excited with

9-12

volts DC.

The

field coil shoes that hold the coil securely to the gen-

erator housing are held in place by bolts that must be

properly tightened when the coil and shoe are installed to

the generator housing. When connecting the coils in

series ensure the butt connections are good and secure

and positioned away from rotating parts.

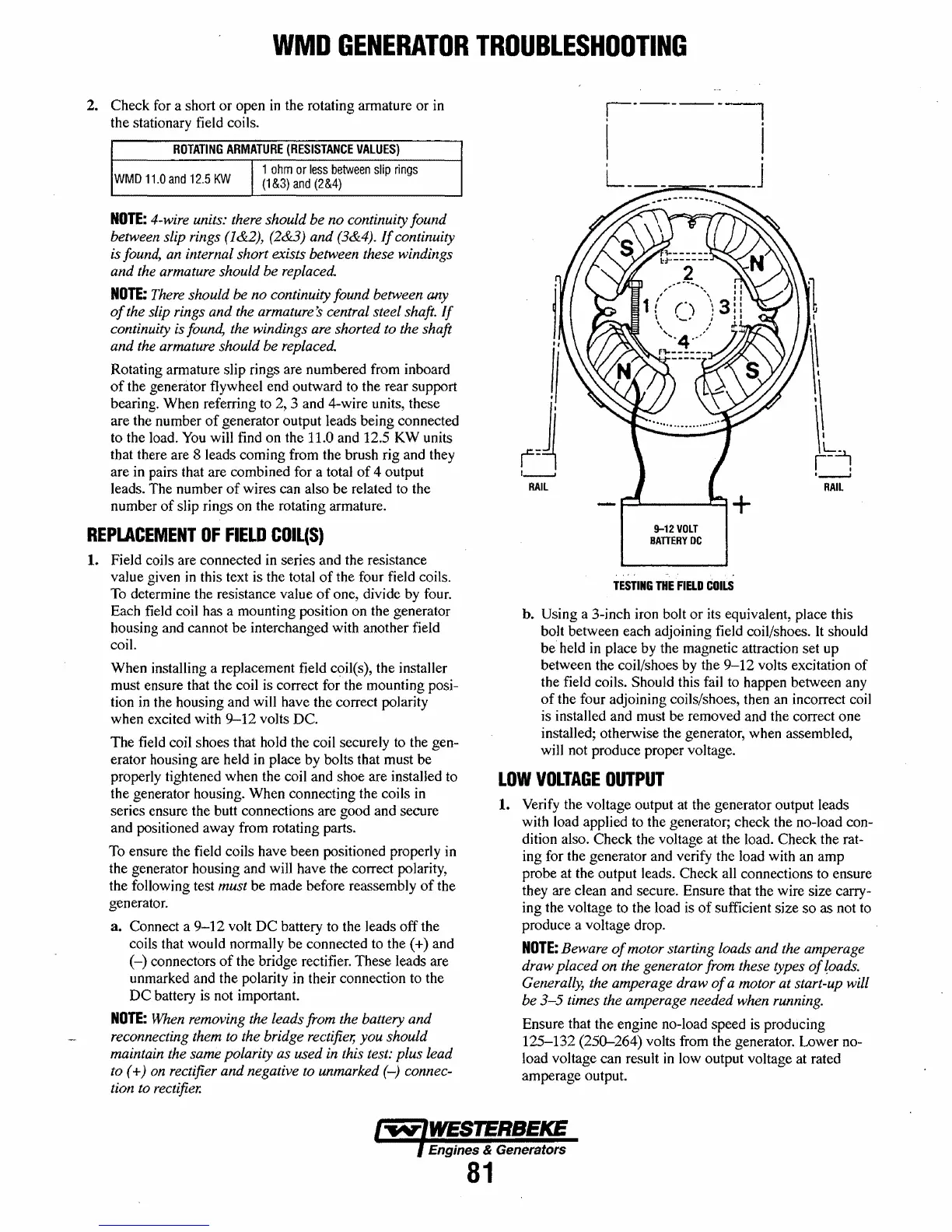

To ensure the field coils have been positioned properly in

the generator housing and will have the correct polarity,

the following test

must be made before reassembly

of

the

generator.

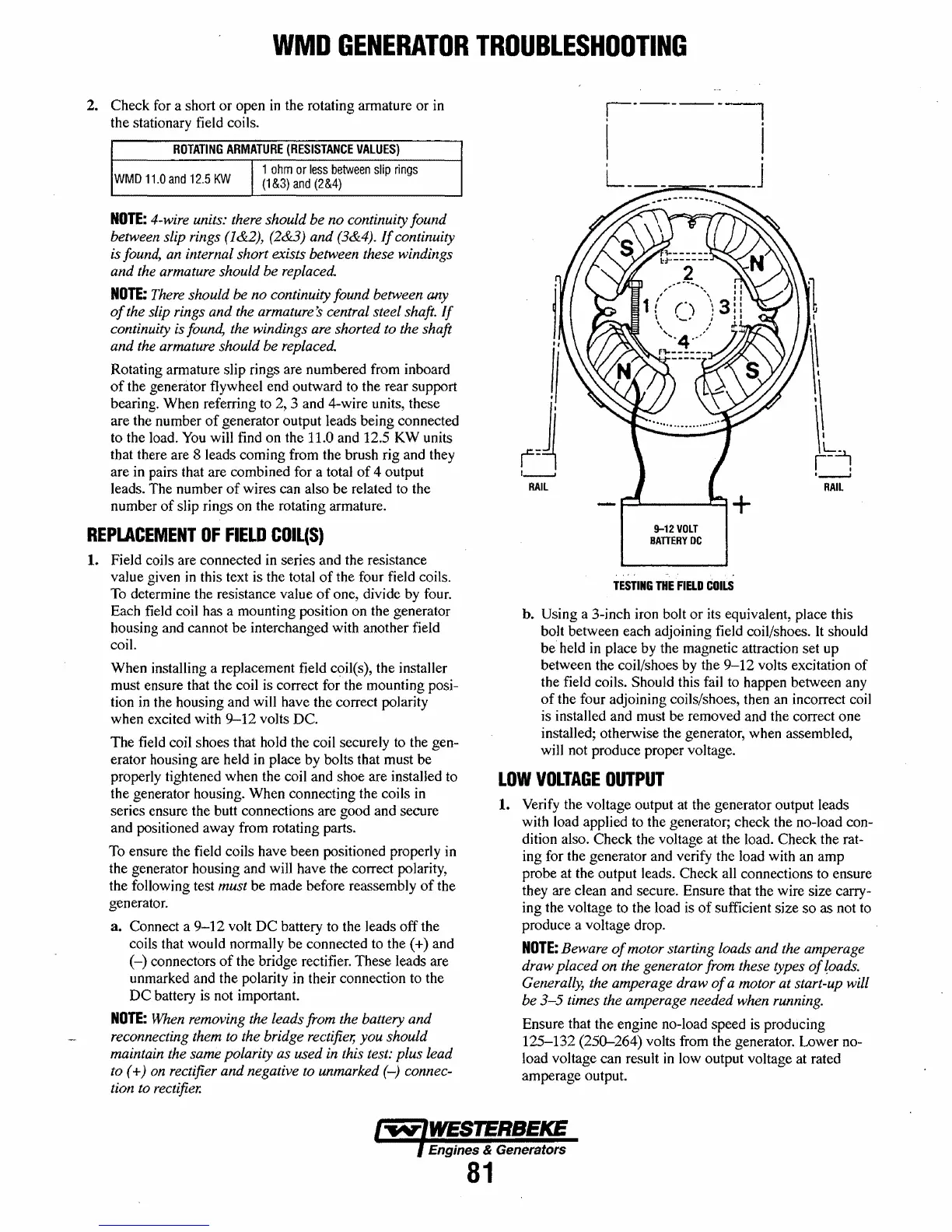

3.

Connect a

9-12

volt

DC

battery to the leads

off

the

coils that would normally be connected to the

(+) and

(-)

connectors

of

the bridge rectifier. These leads are

unmarked and the polarity in their connection to the

DC

battery is not important.

NOTE:

When removing the leads from the battery and

reconnecting them to the bridge rectifier, you should

maintain the same polarity as used in this test: plus lead

to

(+) on rectifier and negative to unmarked

(-)

connec-

tion to rectifier.

j

I,

II

I:~

1----1

RAil

I·----~

i j

~

__

J

9-12

VOLT

BATTERY

DC

TESTING

THE

FIELD

COILS

~

I

'\

\'

,\

~~!

"---J

RAIL

h. Using a 3-inch iron bolt

or

its equivalent, place this

bolt between each adjoining field coil/shoes.

It

should

be

held in place by the magnetic attraction set up

between the coil/shoes by the

9-12

volts excitation

of

the field coils. Should this fail to happen between any

of

the four adjoining coils/shoes, then an incorrect coil

is installed and must

be

removed and the correct one

installed; otherwise the generator, when assembled,

will not produce proper voltage.

LOW

VOLTAGE

OUTPUT

1.

Verify the voltage output at the generator output leads

with load applied to the generator; check the no-load con-

dition also. Check the voltage at the load. Check the rat-

ing for the generator and verify the load with an

amp

probe at the output leads. Check all connections to ensure

they are clean and secure. Ensure that the wire size carry-

ing the voltage to the load is

of

sufficient size

so

as not to

produce a voltage drop.

NOTE:

Beware

of

motor starting loads and the amperage

draw placed on the generator from these types

of

(oads.

Generally, the amperage draw

of

a motor at start-up will

be

3-5

times the amperage needed when running.

Ensure that the engine no-load speed is producing

125-132

(250-264)

volts from the generator. Lower no-

load voltage can result

in

low output voltage at rated

amperage output.

Engines & Generators

81

Loading...

Loading...