FUEL

SYSTEM

DESCRIPTION

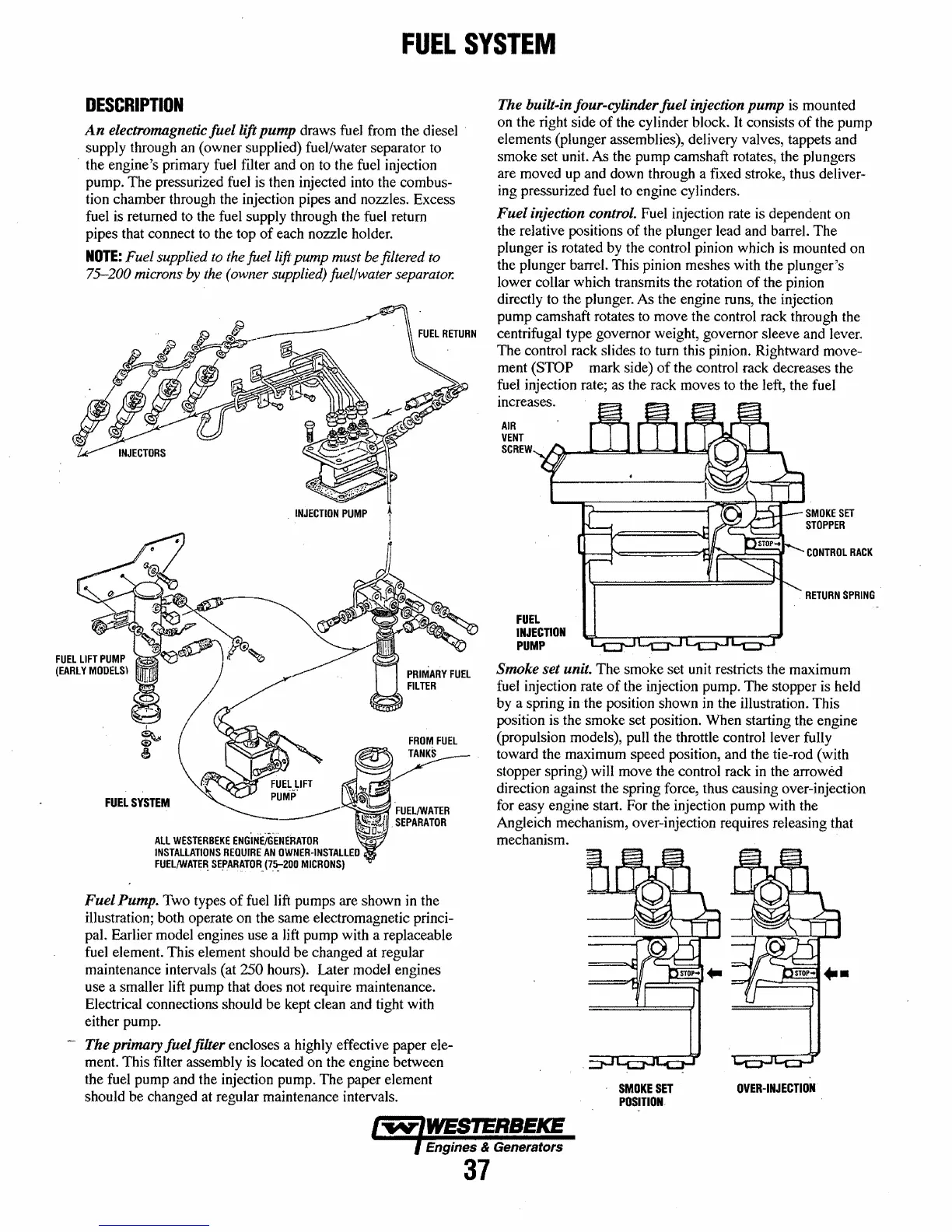

An

electrom.agnetic

fuel

lift

pump

draws fuel from the diesel .

supply through

an

(owner supplied) fuel/water separator to

. the engine's primary fuel filter and on to the fuel injection

pump. The pressurized fuel is then injected into the combus-

tion chamber through the injection pipes and nozzles. Excess

fuel is returned to the fuel supply through the fuel return

pipes that connect to the top

of

each nozzle holder.

NOTE:

Fuel supplied to the fuel lift

pump

must be filtered to

75-200 microns by the (owner supplied) fuel/water separator.

FUEL

SYSTEM

ALL

WESTERBEKE

ENG'lNEiGENERATOR

INSTALLATIONS

REQUIRE

AN

OWNER·INSTALLED

FUEL/WATER.

SE~ARATOR.

(7.5:-200

MICRONS)

FROM

FUEL

,~

FUEL/WATER

.

SEPARATOR

Fuel

Pump. Two types

of

fuel lift pumps are shown

in

the

illustration; both operate on the same electromagnetic princi-

pal. Earlier model engines use a lift pump with a replaceable

fuel element. This element should be changed at regular

maintenance intervals (at

250 hours). Later model engines

use a smaller lift pump that does not require maintenance.

Electrical connections should be kept clean and tight with

either pump.

The primary

fuel

filter encloses a highly effective paper ele-

ment. This filter assembly is located on the engine between

the fuel pump and the injection pump. The paper element

should be changed at regular maintenance intervals.

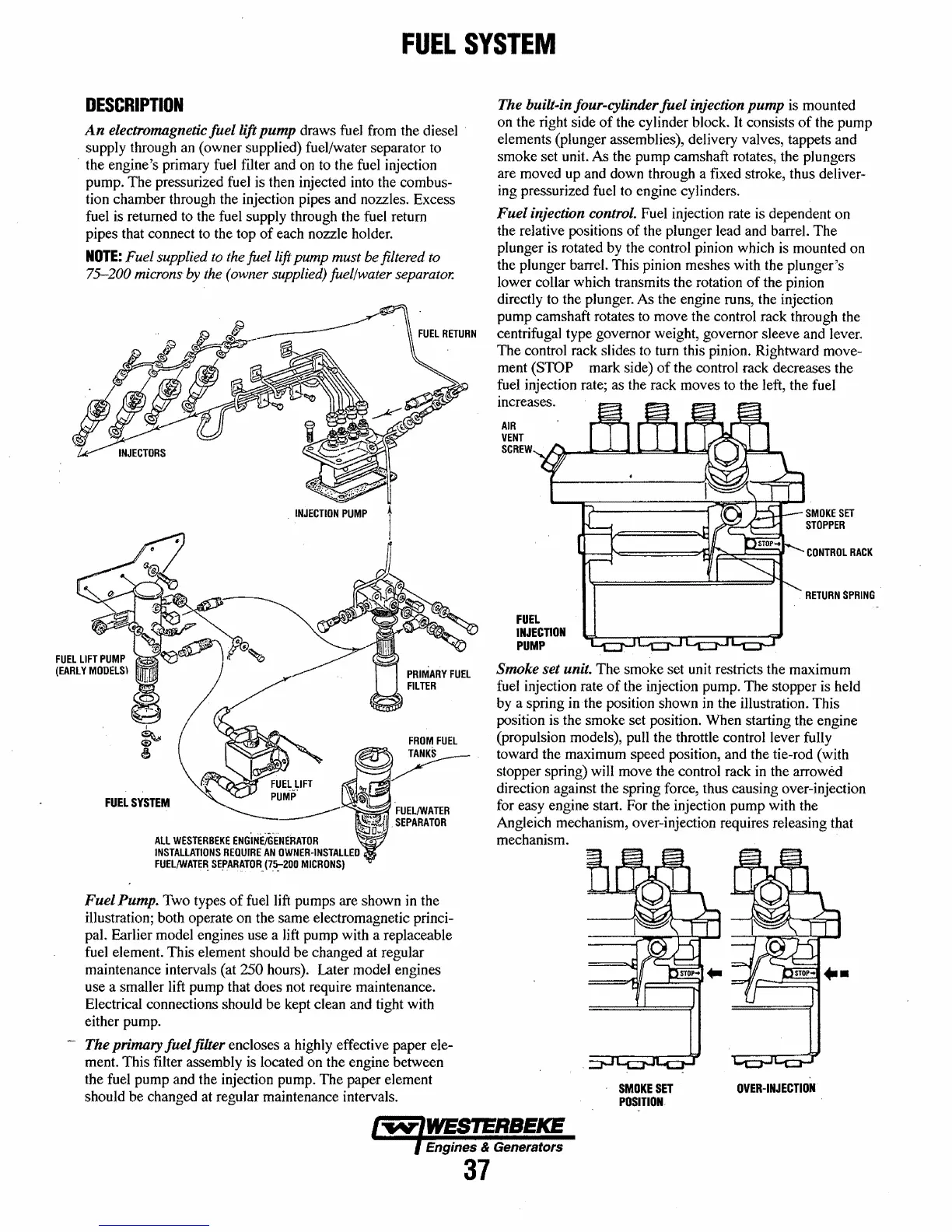

The built·in four-cylinder

fuel

injection

pump

is mounted

on the right side

of

the cylinder block.

It

consists

of

the pump

elements (plunger assemblies), delivery valves, tappets and

smoke set unit. As the pump camshaft rotates, the plungers

are moved up and down through a fixed stroke, thus deliver-

ing pressurized fuel to engine cylinders.

Fuel

injection control. Fuel injection rate is dependent on

the relative positions

of

the plunger lead and barrel. The

plunger is rotated by the control pinion which is mounted on

the plunger barrel. This pinion meshes with the plunger's

lower collar which transmits the rotation

of

the pinion

directly to the plunger. As the engine runs, the injection

pump camshaft rotates to move the control rack through the

centrifugal type governor weight, governor sleeve and lever,

The control rack slides to tum this pinion. Rightward move-

ment

(STOP mark side)

of

the control rack decreases the

fuel injection rate; as the rack moves to the left, the fuel

increases.

AIR

VENT

SCREW

.....

~~_.-.::::=:lII.oo.I=:=:::::lI

__

~

FUEL

INJECTION

PUMP

SMOKE

SET

STOPPER

CONTROL

RACK

RETURN

SPRING

Smoke set unit. The smoke set unit restricts the maximum

fuel injection rate

of

the injection pump. The stopper is held

by a spring in the position shown

in

the illustration. This

position is

the

smoke set position. When starting the engine

(propulsion models), pull the throttle control lever fully

toward the maximum speed position, and the tie-rod (with

stopper spring) will move the control rack in the arrowed

direction against the spring force, thus causing over-injection

for easy engine start. For the injection pump with the

Angleich mechanism, over-injection requires releasing that

mechanism.

SMOKE

SET

POSITION

OVER-INJECTION

Engines & Generators

37

Loading...

Loading...