CYLINDER

BLOCK

SERVICE

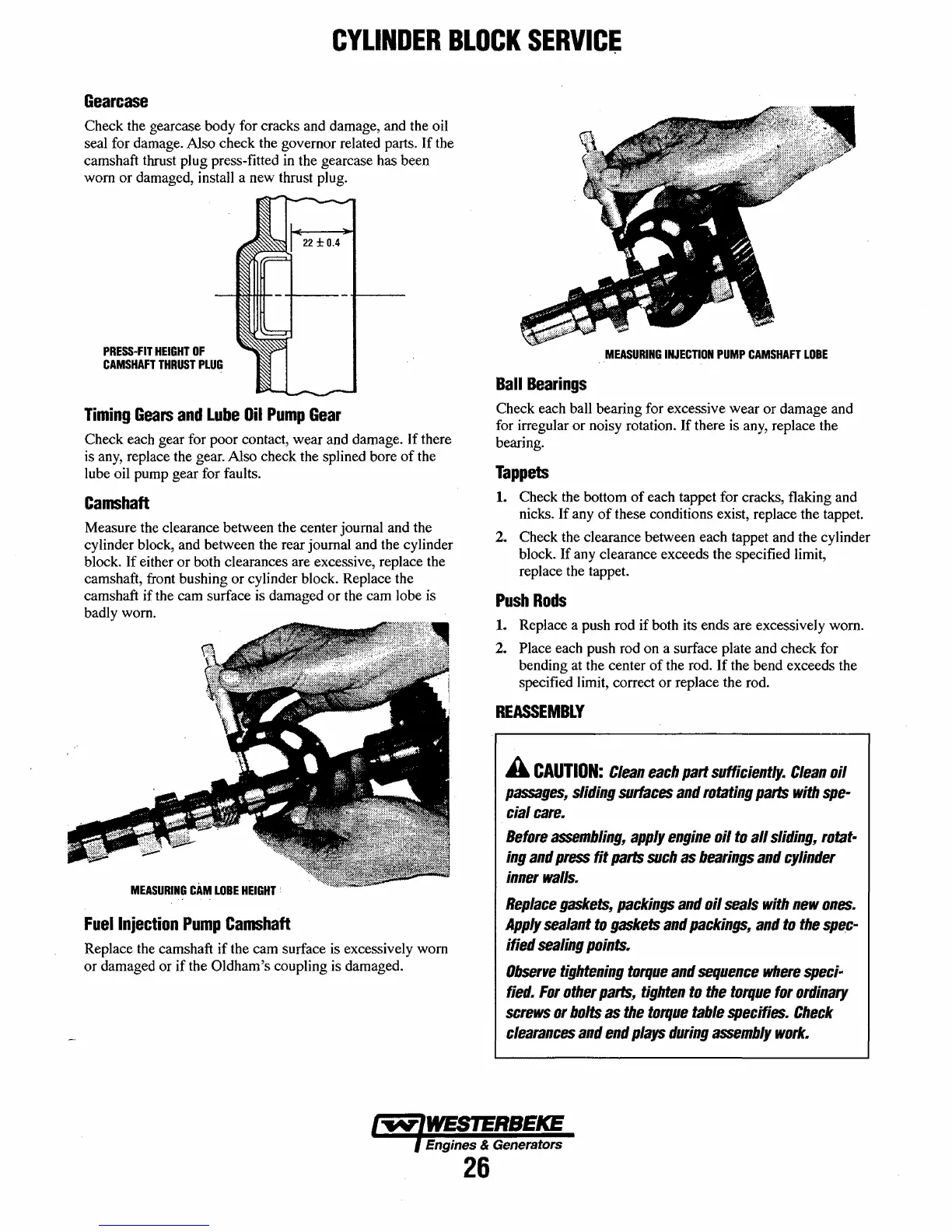

Gearcase

Check the gearcase body for cracks and damage, and the oil

seal for damage. Also check the governor related parts. If the

camshaft thrust plug press-fitted in the gearcase has been

worn or damaged, install a new thrust plug.

PRESS-FIT

HEIGHT

OF

CAMSHAFT

THRUST

PLUG

22

±

0.4

Timing

Gears

and

Lube

Oil

Pump

Gear

Check each gear for poor contact, wear and damage. If there

is any, replace the gear. Also check the splined bore

of

the

lube oil pump gear for faults.

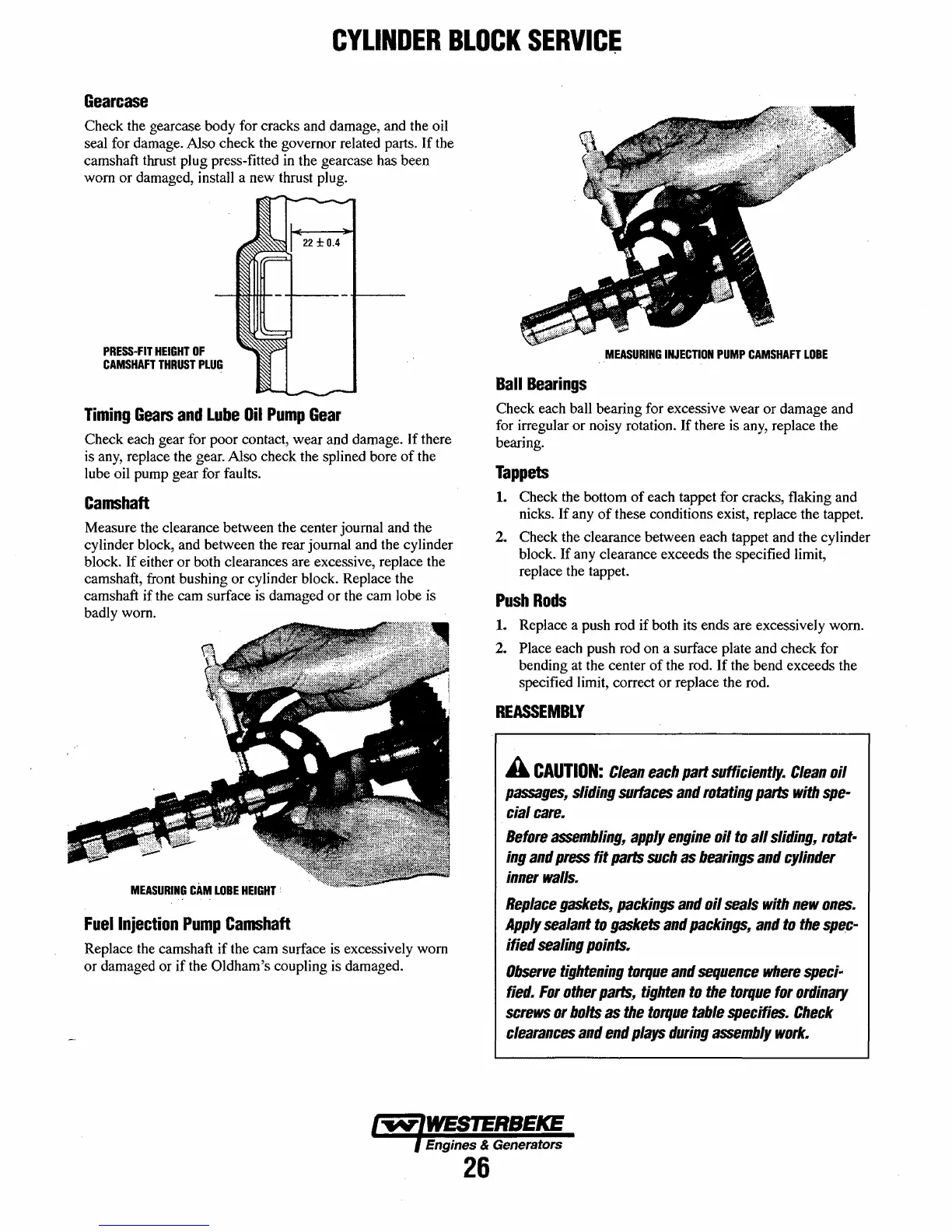

Camshaft

Measure the clearance between the center journal and the

cylinder block, and between the rear journal and the cylinder

block. If either

or

both clearances are excessive, replace the

camshaft, front bushing or cylinder block. Replace the

camshaft

if the cam surface is damaged

or

the cam lobe is

badly worn.

MEASURING

CAM

LOBE

HEIGHT'

Fuel

Injection

Pump

Camshaft

Replace the camshaft

if

the cam surface

is

excessively worn

or

damaged or if the Oldham's coupling is damaged.

MEASURING

INJECTION

PUMP

CAMSHAFT

LOBE

Ball

Bearings

Check each ball bearing for excessive wear or damage and

for irregular

or

noisy rotation. If there is any, replace the

bearing.

Tappets

1. Check the bottom

of

each tappet for cracks, flaking and

nicks. If any

of

these conditions exist, replace the tappet.

2. Check the clearance between each tappet and the cylinder

block. If any clearance exceeds the specified limit,

replace the tappet.

Push

Rods

1. Replace a push rod if both its ends are excessively worn.

2. Place each push rod on a surface plate and check for

bending at the center

of

the rod. If the bend exceeds the

specified limit, correct or replace the rod.

REASSEMBLY

A

CAUTION:

Clean

each

part

sufficiently.

Clean

oil

passages,

sliding

surfaces

and

rotating

parts

with

spe-

cial

care.

Before

assembling,

apply

engine

oil

to

all

sliding,

rotat-

ing

and

press

fit

parts

such

as

bearings

and

cylinder

inner

walls.

Replace

gaskets,

packings

and

oil

seals

with

new

ones.

Apply

sealant

to

gaskets

and

packings,

and

to

the

spec-

ified

sealing

points.

Observe

tightening

torque

and

sequence

where

speci-

fied.

For

other

parts,

tighten

to

the

torque

for

ordinary

screws

or

bolts

as

the

torque

table

specifies.

Check

clearances

and

end

plays

during

assembly

work.

Engines & Generators

26

Loading...

Loading...