FUEL

SYSTEM

SERVICE

DISASSEMBLY

Fuel

Filter

Remove

the retaining nut, O-ring and filter element.

Fuel

Lift

Pump

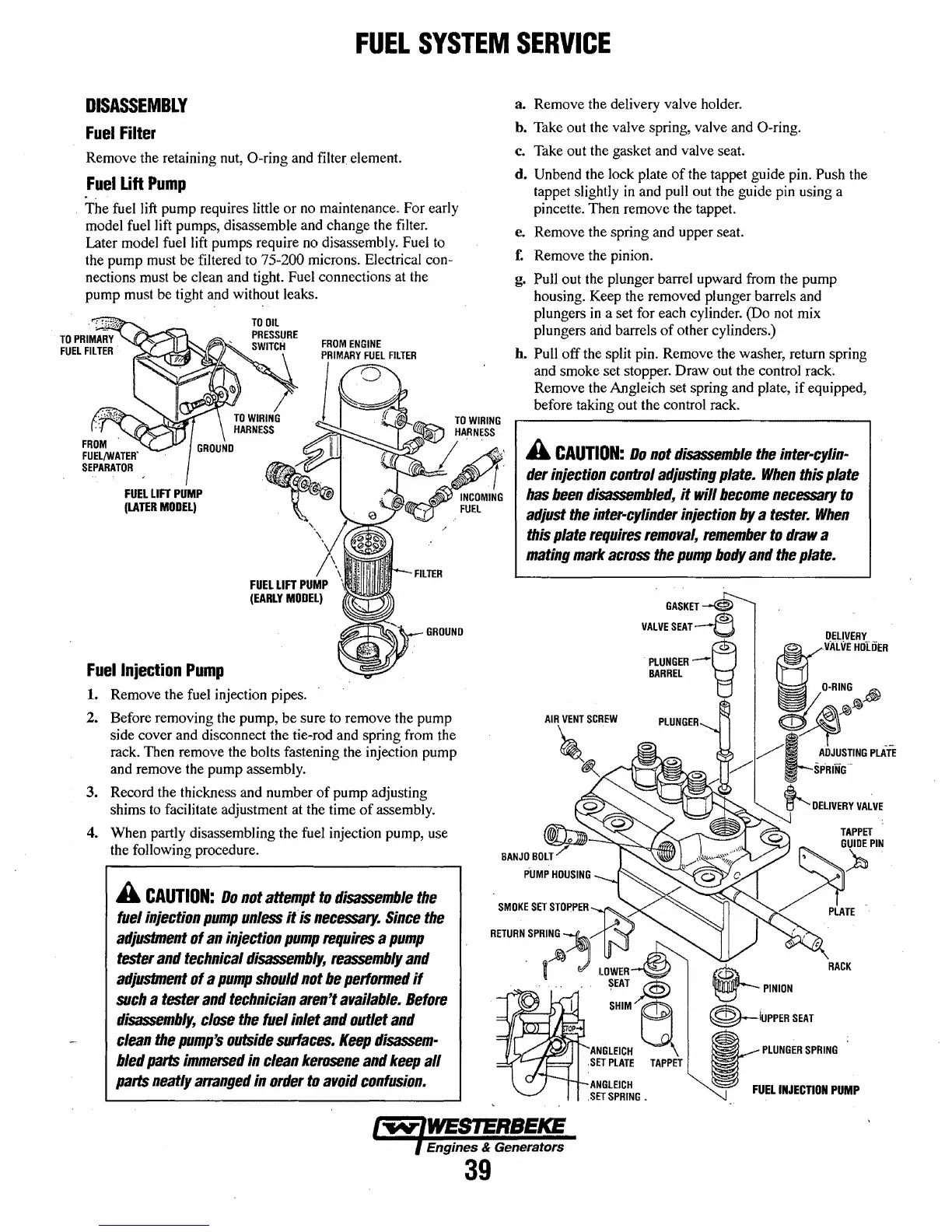

The

fuel lift

pump

requires little

or

no maintenance. For early

model fuel lift pumps, disassemble and

change

the filter.

Later model fuel lift

pumps

require no disassembly. Fuel to

the

pump

must

be

filtered to

75-200

microns. Electrical

con-

nections must

be

clean and tight. Fuel connections at the

pump

must

be

tight and without leaks.

FUEL

LIFT

PUMP

(LATER

MODEL)

Fuel

Injection

Pump

1. Remove the fuel injection pipes.

FROM

ENGINE

PRIMARY

FUEL

FILTER

j

2. Before removing the

pump,

be

sure to

remove

the

pump

side

cover

and disconnect

the

tie-rod and

spring

from the

rack.

Then

remove the bolts fastening the injection

pump

and remove the

pump

assembly.

3.

Record the thickness and

number

of

pump

adjusting

shims to facilitate adjustment at the time

of

assembly.

4.

When

partly disassembling

the

fuel injection pump, use

the following procedure.

A

CAUTION:

00

not

attempt

to

disassemble

the

fuel

injection

pump

unless

itis

necessary.

Since

the

adjustment

of

an

injection

pump

requires

a

pump

tester

and

technical

disassembly,

reassembly

and

adjustment

of a

pump

should

not

be

performed

if

such

a

tester

and

technician

aren't

available.

Before

disassembly,

close

the

fuel

inlet

and

outlet

and

clean

the

pump's

outside

surfaces.

Keep

disassem-

bled

parts

immersed

in

clean

kerosene

and

keep

all

parts

neatly

arranged

in

order

to

avoid

confusion.

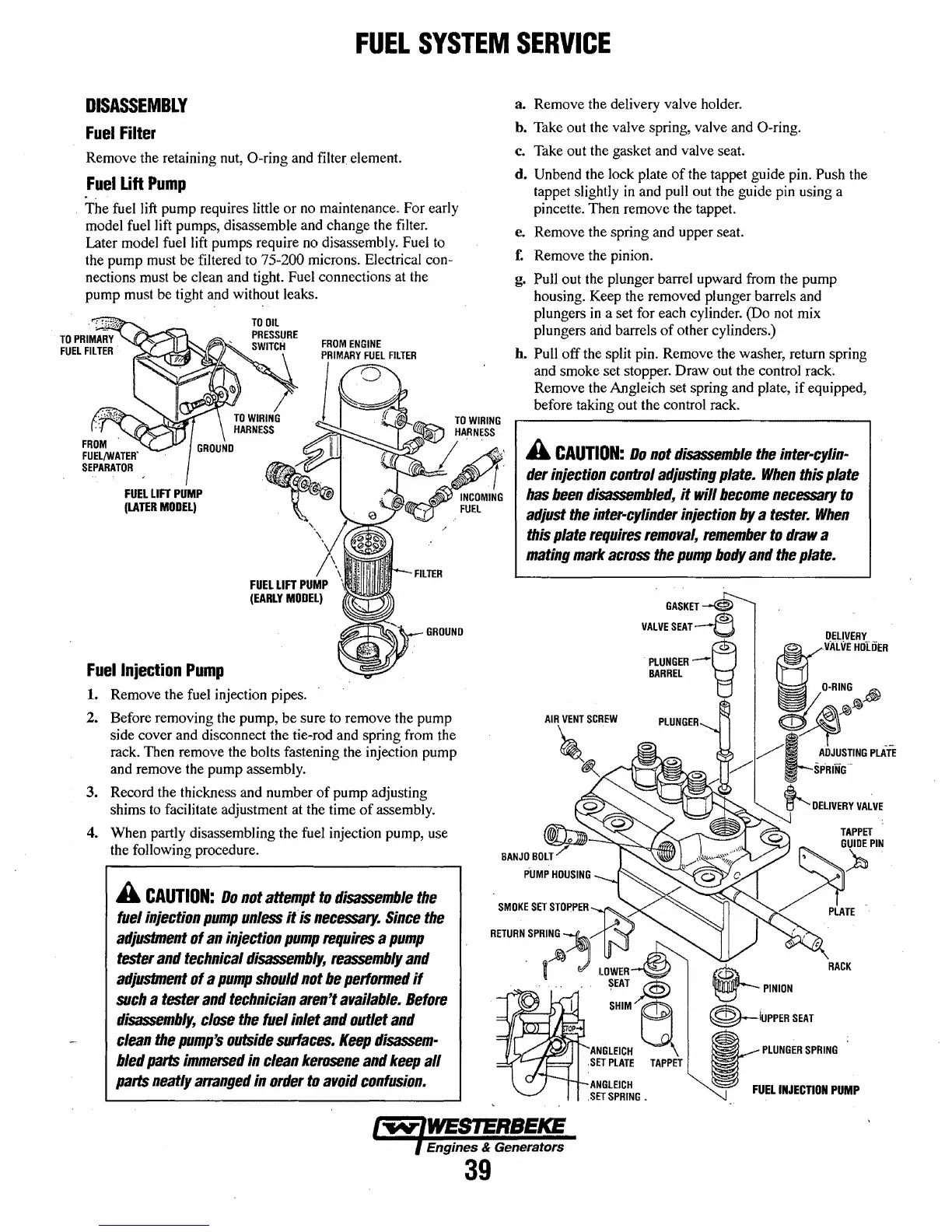

a.

Remove

the delivery valve holder.

h. Take out the valve spring, valve and O-ring.

c. Take out the gasket and valve seat.

d.

Unbend the lock plate

of

the tappet guide pin. Push the

tappet slightly in and pull out the guide pin using a

pincette.

Then

remove

the tappet.

e.

Remove

the

spring

and upper seat.

f.

Remove

the pinion.

g.

Pull out the plunger barrel upward from the

pump

housing. Keep the removed plunger barrels and

plungers in a set for each cylinder. (Do not mix

plungers

arid barrels

of

other cylinders.)

h.

Pull

off

the split pin.

Remove

the washer, return spring

and

smoke

set stopper.

Draw

out the control rack.

Remove

the AngJeich set spring and plate,

if

equipped,

before taking out the control rack.

A

CAUTION:

00

not

disassemble

the

inter-cylin"

der

injection

control

adjusting

plate.

When

this

plate

has

been

disassembled,

it

will

become

necessary

to

adjust

the

inter-cylinder

injection

by

a

tester.

When

this

plate

requires

removal,

remember

to

draw

a

mating

mark

across

the

pump

body

and

the

plate.

GASKET

i::t)

VALVE

SEAT--e

DELIVERY

ANGLEICH

,SET

SPRING

•

PLUNGER-~

BARREL

8"

0;

VALVE

HottiER

O-RING

jj)

~~~

/1/

_ADJUSTING

PLATE

"/

t-SPRfNG

~

DELIVERY

VALVE

@--PINIDN

~IUPPER

SEAT

RACK

~

PLUNGER

SPRING

FUEL

INJECTION

PUMP

Engines & Generators

39

Loading...

Loading...