STARTER/SOLENOID

SERVICE

DESCRIPTION

The swrtercan

be

roughly divided into the following sections:

• A motor section which generates a drive power.

• An overrunning clutch section which transmits an arma-

ture torque, preventing motor overrun after starting.

• A switch section (solenoid) which is operated when

actuating the overrunning clutch through a lever and

which supplies load current to the motor.

The starter is a new type, small, light-weight, and is called a

high-speed internal-reduction starter.

Its differences

in

con-

struction from conventional starters are

as

follows:

•

In

conventional starters, the pinion slides on the motor

shaft (armature shaft).

In

the new type

of

starter, the pin-

ion shaft is separate from the motor shaft; the pinion

slides only

on

the pinion shaft.

• A reduction gear is installed between the motor shaft and

the pinion shaft.

• The pinion sliding part is not exposed outside the starter .

so

that the pinion

may

slide smoothly without becoming

fouled with dust and grease.

• The motor shaft is supported at both ends on ball bear-

ings. The lever mechanism, switch and overrunning

clutch inner circuit are identical to conventional ones.

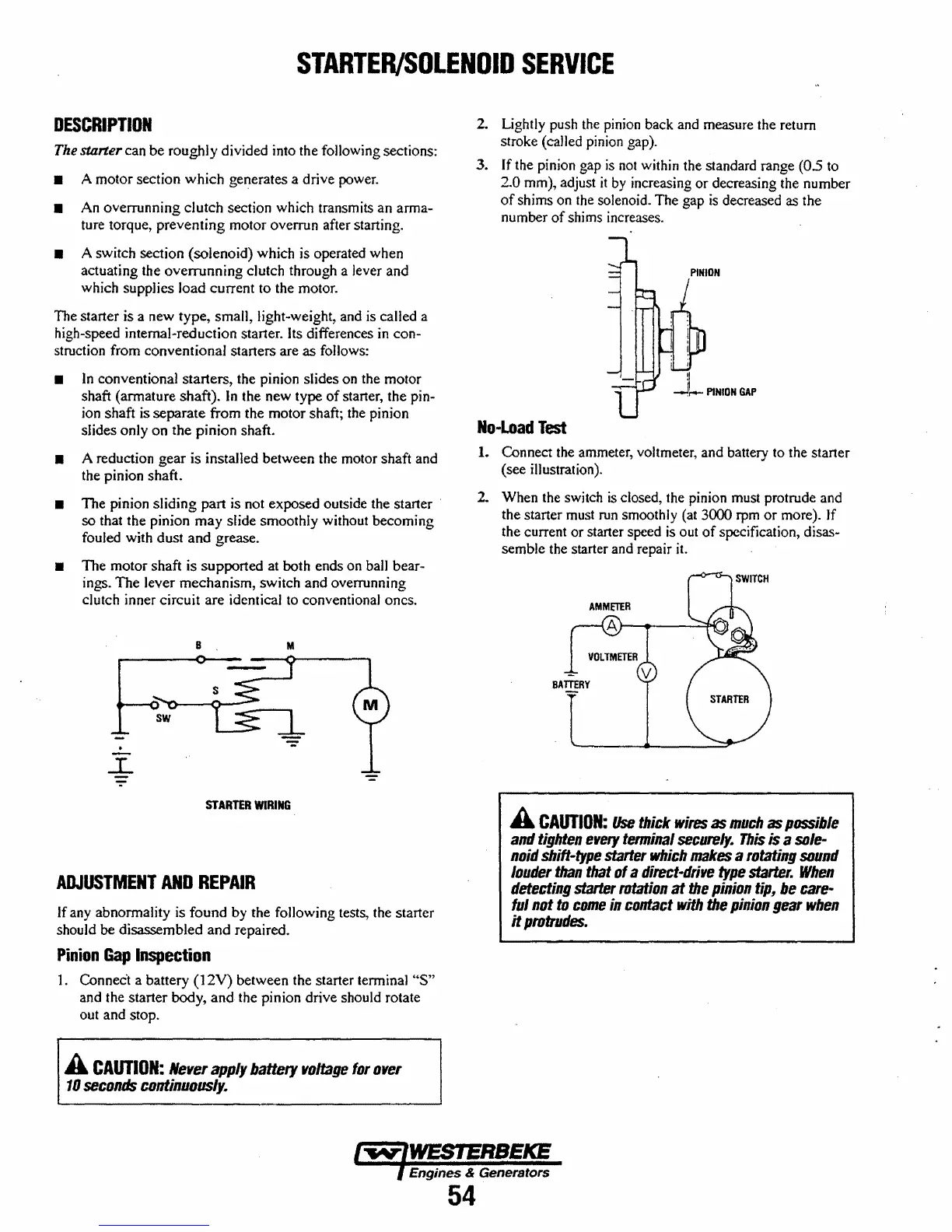

B

M

~

STARTER

WIRING

ADJUSTMENT

AND

REPAIR

If any abnormality is found by the following tests, the starter

should

be disassembled

and

repaired.

Pinion

Gap

Inspection

1.

Conned

a battery

(12V)

between the starter lenninaJ

"S"

and the starter body,

and

the pinion drive should rotate

out and stop.

A

CAUTION:

Never

apply

battery

voltage

for

over

10

seconds

cominuously.

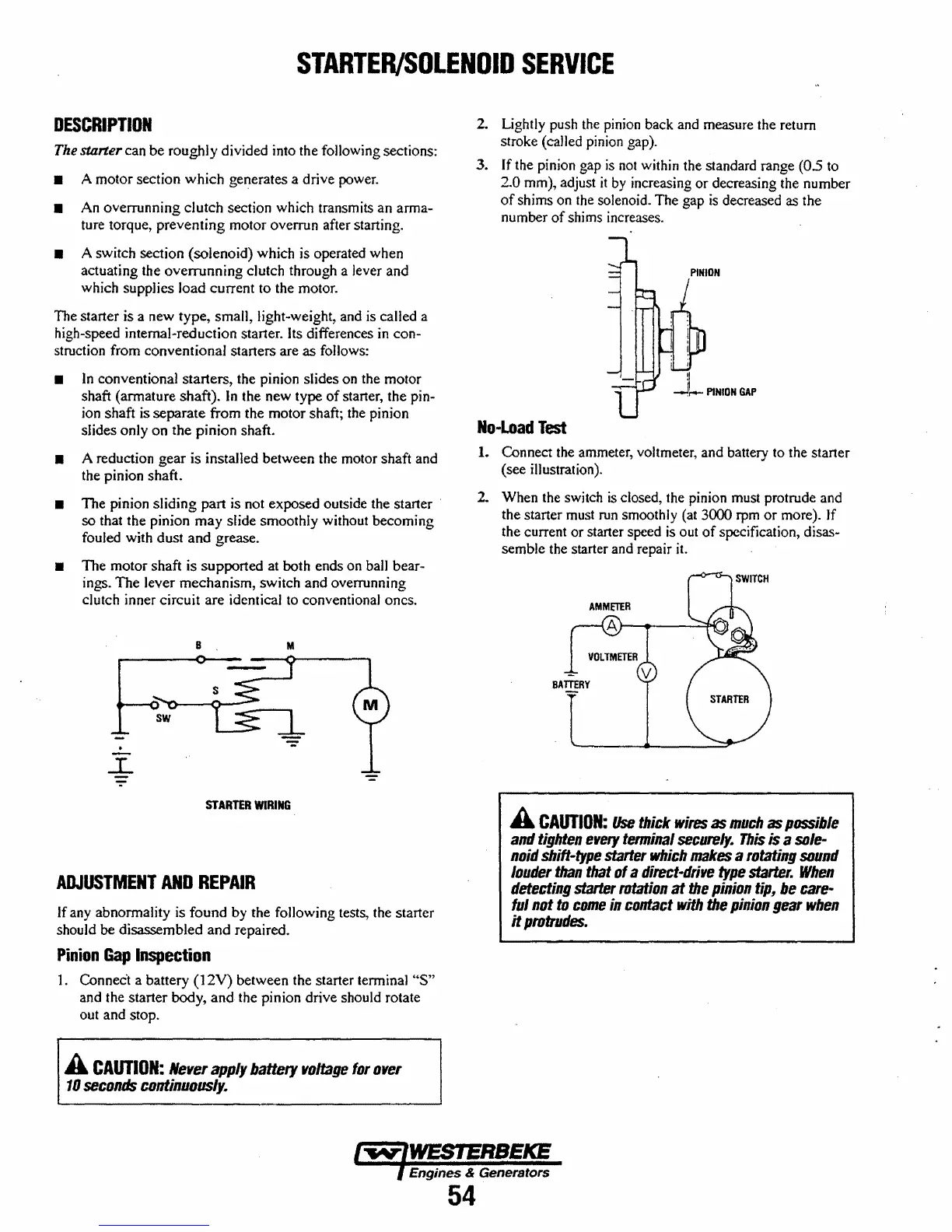

2. Lightly push the pinion back and measure the return

stroke (called pinion gap).

3.

If the pinion gap

is

not

within the standard range (0.5 to

2.0 mm), adjust

it

by

increasing

or

decreasing the number

of

shims on the solenoid. The gap

is

decreased as the

number

of

shims increases.

No-Load

Test

1.

Connect the ammeter, voltmeter, and battery to the starter

(see illustration).

2. When the switch

is

closed, the pinion must protrude and

the starter must

run

smoothly (at

3000

rpm

or

more). If

the current or starter speed is out

of

specification, disas-

semble the starter and repair it.

A

CAUTION:

Use

thick

wires

as

much

as

possible

and

tighten

every

terminal

securely.

This

is a

sole-

noid

shift-type

starter

which

makes

a

rotating

sound

louder

than

that

of a

direct-drive

type

starter.

When

detecting

starter

rotation

at

the

pinion

tip,

be

care

..

ful not

to

come

in

contact

with

the

pinion

gear

when

it

protrudes.

Engines & Generators

54

Loading...

Loading...