ENGINE

SHUTOFF

ENGINES

WITH

MANUAL

STOP

(Standard)

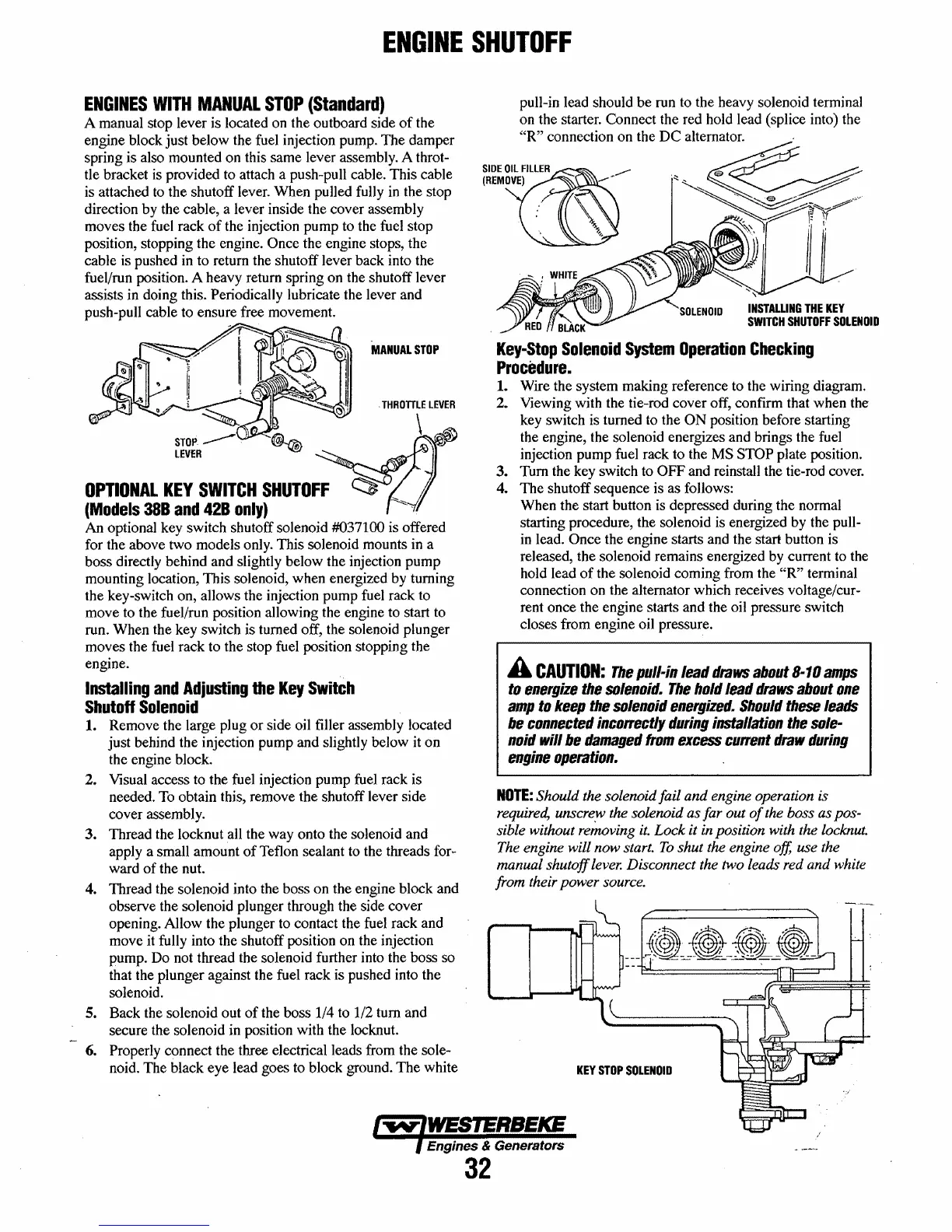

A manual stop lever is located on the outboard side

of

the

engine block just below the fuel injection pump. The damper

spring is also mounted on this same lever assembly. A throt-

tle bracket

is

provided to attach a push-pull cable. This cable

is attached

to

the shutoff lever. When pulled fully

in

the stop

direction by the cable, a lever inside the cover assembly

moves the fuel rack

of

the injection pump to the fuel stop

position, stopping the engine.

Once the engine stops, the

cable is pushed in to return the shutoff lever back into the

fuel/run position. A heavy return spring on the shutoff lever

assists in doing this. Periodically lubricate the lever and

push-pull cable to ensure free movement.

~/Id

~~?'

· i I

,~-:

,

MANUAL

STOP

.

THROTTLE

LEVER

\

OPTIONAL

KEY

SWITCH

SHUTOFF

(Models

388

and

428

only)

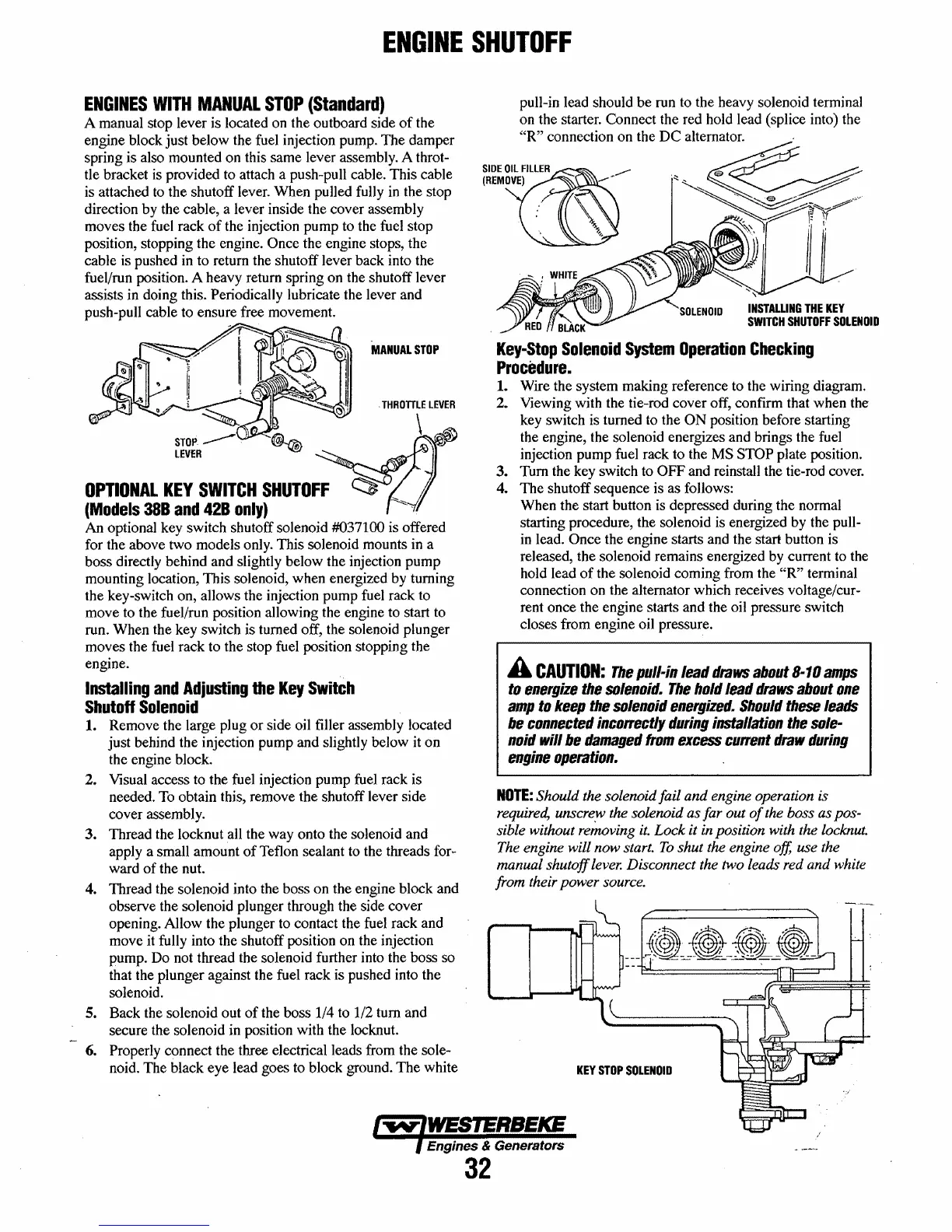

An optional key switch shutoff solenoid #037100 is offered

for the above two models only. This solenoid mounts in a

boss directly behind and slightly below the injection pump

mounting location, This solenoid, when energized by turning

the key-switch on, allows the injection pump fuel rack to

move to the fuel/run position allowing the engine to start to

run. When the key switch is turned off, the solenoid plunger

moves the fuel rack to the stop fuel position stopping the

engine.

Installing

and

Adjusting

the

Key

Switch

Shutoff

Solenoid

1. Remove the large plug

or

side oil filler assembly located

just behind the injection pump and slightly below it on

the engine block.

2. Visual access to the fuel injection pump fuel rack is

needed.

To

obtain this, remove the shutoff lever side

cover assembly.

3. Thread the locknut all the way onto the solenoid and

apply a small amount

of

Teflon sealant to the threads for-

ward

of

the nut.

4. Thread the solenoid into the boss on the engine block and

observe the solenoid plunger through the side cover

opening. Allow the plunger to contact the fuel rack and

move

it

fully into the shutoff position on the injection

pump. Do not thread the solenoid further into the boss so

that the plunger against the fuel rack is pushed into the

solenoid.

S.

Back the solenoid out

of

the boss 1/4 to 1/2 tum and

secure the solenoid in position with the locknut.

6. Properly connect the three electrical leads from the sole-

noid. The black eye lead goes to block ground.

The

white

pull-in lead should be run to the heavy solenoid terminal

on the starter. Connect the red hold lead (splice into) the

"R"

connection on the

DC

alternator.

<,~e~

~

",,~Y'>'"

, ,

~,

I "

SIDEO~l.FlllER

...........

(REMOVE)

--

:,

'\

Key-Stop

Solenoid

System

Operation

Checking

Procedure.

1. Wire the system making reference to the wiring diagram.

2. Viewing with the tie-rod cover off, confirm that when the

key switch is turned to the

ON

position before starting

the engine, the solenoid energizes and brings the fuel

injection pump fuel rack to the

MS STOP plate position.

3. Tum the key switch to

OFF and reinstall the tie-rod cover.

4.

The

shutoff sequence is as follows:

When the start button is depressed during the normal

starting procedure, the solenoid is energized by the pull-

in

lead. Once the engine starts and the start button is

released, the solenoid remains energized by current to the

hold lead

of

the solenoid coming from the

"R"

terminal

connection on the alternator which receives voltage/cur-

rent once the engine starts and the oil pressure switch

closes from engine oil pressure.

A

CAUTION:

The

pull-in

lead

draws

about

8-10

amps

to

energize

the

solenoid.

The

hold

lead

draws

about

one

amp

to

keep

the

solenoid

energized.

Should

these

leads

be

connected

incorrectly

during

installation

the

sole-

noid

will

be

damaged

from

excess

current

draw

during

engine

operation.

NOTE:

Should the solenoid fail and engine operation is

required,

unscre,w the solenoid as far out

of

the boss as pos-

sible without removing

it.

Lock

it in position with the locknut.

The engine will now start.

To

shut the engine off, use the

manual shutoff lever. Disconnect the two leads red and white

from their power source.

KEY

STOP

SOLENOID

Engines & Generators

32

Loading...

Loading...