LUBRICATION

SYSTEM

SER\(ICE

DESCRIPTION

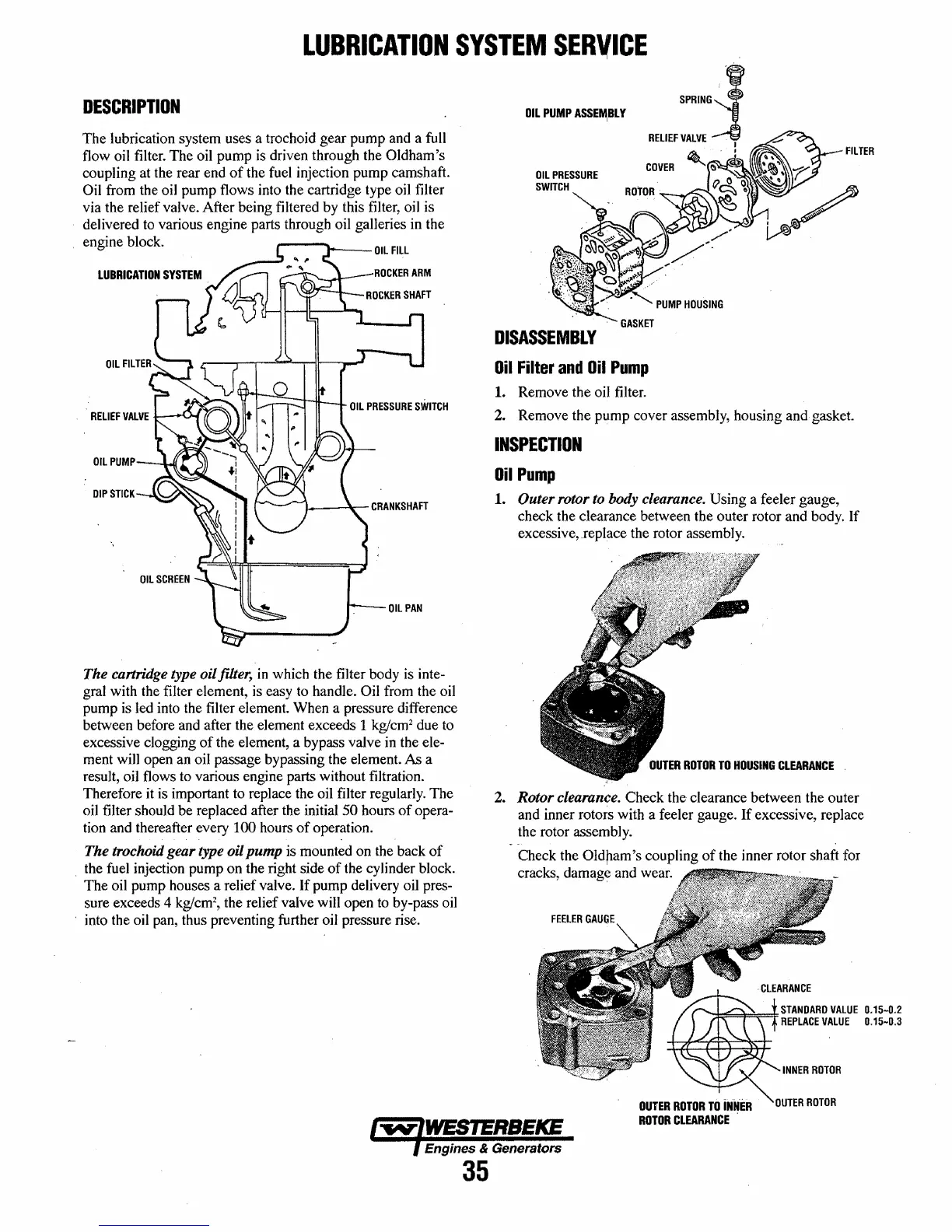

The lubrication system uses a trochoid gear pump and a full

flow oil filter. The oil pump is driven through the

Oldham's

coupling at the rear end

of

the fuel injection pump camshaft.

Oil from the oil pump flows into the cartridge type oil filter

via the relief valve. After being filtered by this filter, oil is

delivered to various engine parts through oil galleries in the

engine block.

OIL

PUMP

DIP

STICK

__

..

_"

..........

The cartridge type oil filter,

in

which the filter body is inte-

gral with the filter element, is easy to handle.

Oil from the oil

pump is led into the filter element. When a pressure difference

between before and after the element exceeds 1 kglcm

2

due to

excessive clogging

of

the element, a bypass valve in the ele-

ment will open an oil passage bypassing the element.

As a

result, oil flows to various engine parts without filtration.

Therefore it is important to replace the oil filter regularly. The

oil filter should be replaced after the initial

50

hours

of

opera-

tion and thereafter every

100 hours

of

operation.

The trochoid gear type oil

pump

is mounted on the back

of

. the fuel injection pump on the right side

of

the cylinder block.

The oil pump houses a relief valve.

If

pump delivery oil pres-

sure exceeds 4

kglcm2,

the relief valve will open to by-pass oil

into the oil pan, thus preventing further oil pressure rise.

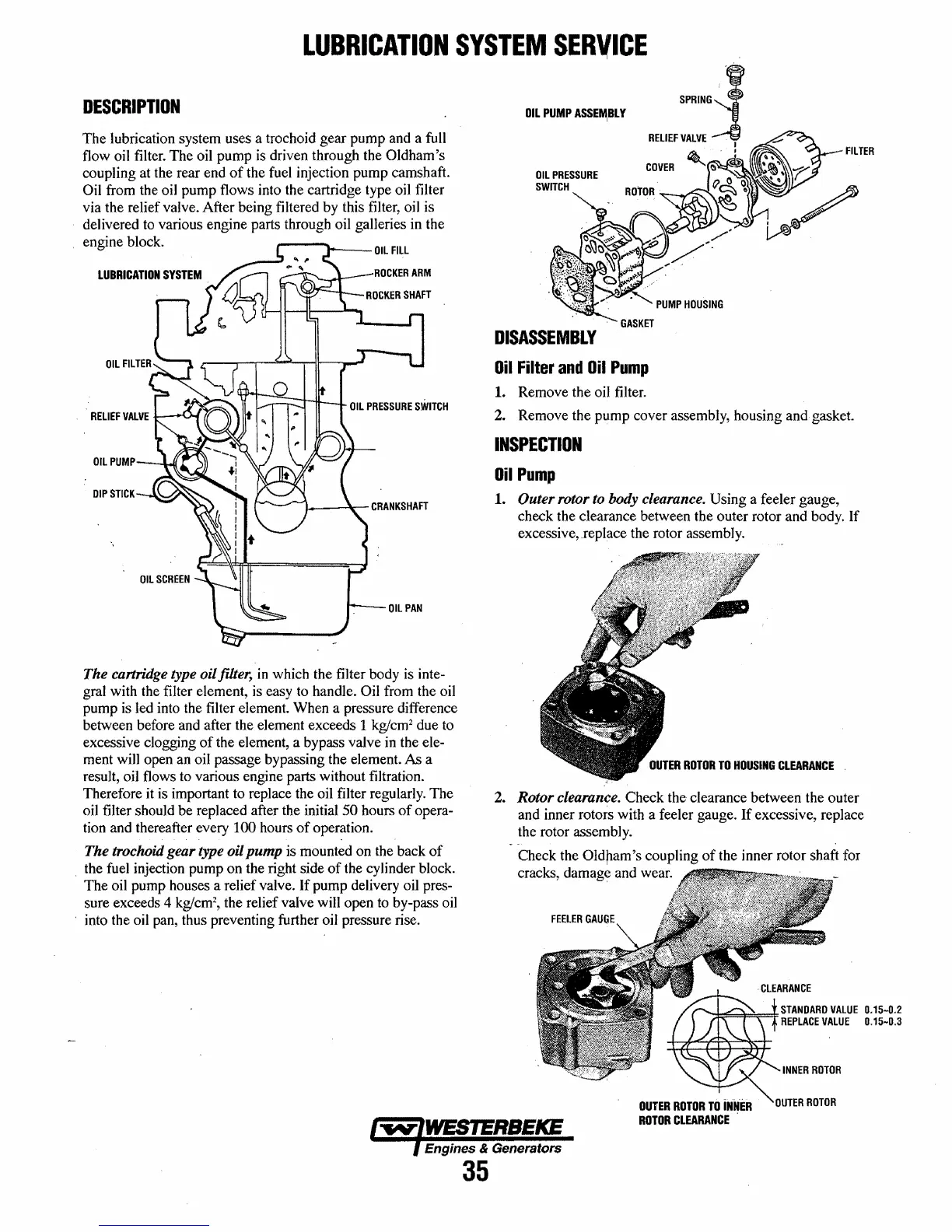

OIL

PUMP

ASSEN\BL

Y

OIL

PRESSURE

SWITCH

DISASSEMBLY

.......

GASKET

Oil

Filter

and

Oil

Pump

1.

Remove the oil filter.

FILTER

2. Remove the pump cover assembly, housing and gasket.

INSPECTION

Oil

Pump

1.

Outer rotor to body clearance. Using a feeler gauge,

check the clearance between the outer rotor and body. If

excessive, .replace the rotor assembly.

OUTER

ROTOR

TO

HOUSING

CLEARANCE

2.

Rotor clearance. Check the clearance between the outer

and inner rotors with a feeler gauge.

If

excessive, replace

the rotor assembly.

Check the

Old pam 's coupling

of

the inner rotor shaft for

cracks, damage and wear.

FEELER

GAU(lE

~'P=~=FSTANDARD

VALUE

0.15-0.2

REPLACE

VALUE

0.15-0.3

OUTER

ROTOR

TO

iNNER

ROTOR

CLEARANCE

.

Engines & Generators

35

Loading...

Loading...