STARTER/SOLENOID

SERVICE

Field

Coil

Inspection

1.

Check for insulation between one end (brush)

of

the coil

and yoke.

2. Check for continuity between both ends (brushes)

of

the

coil.

3. Check the poles and coil for tightness.

FIELD

COIL

TEST

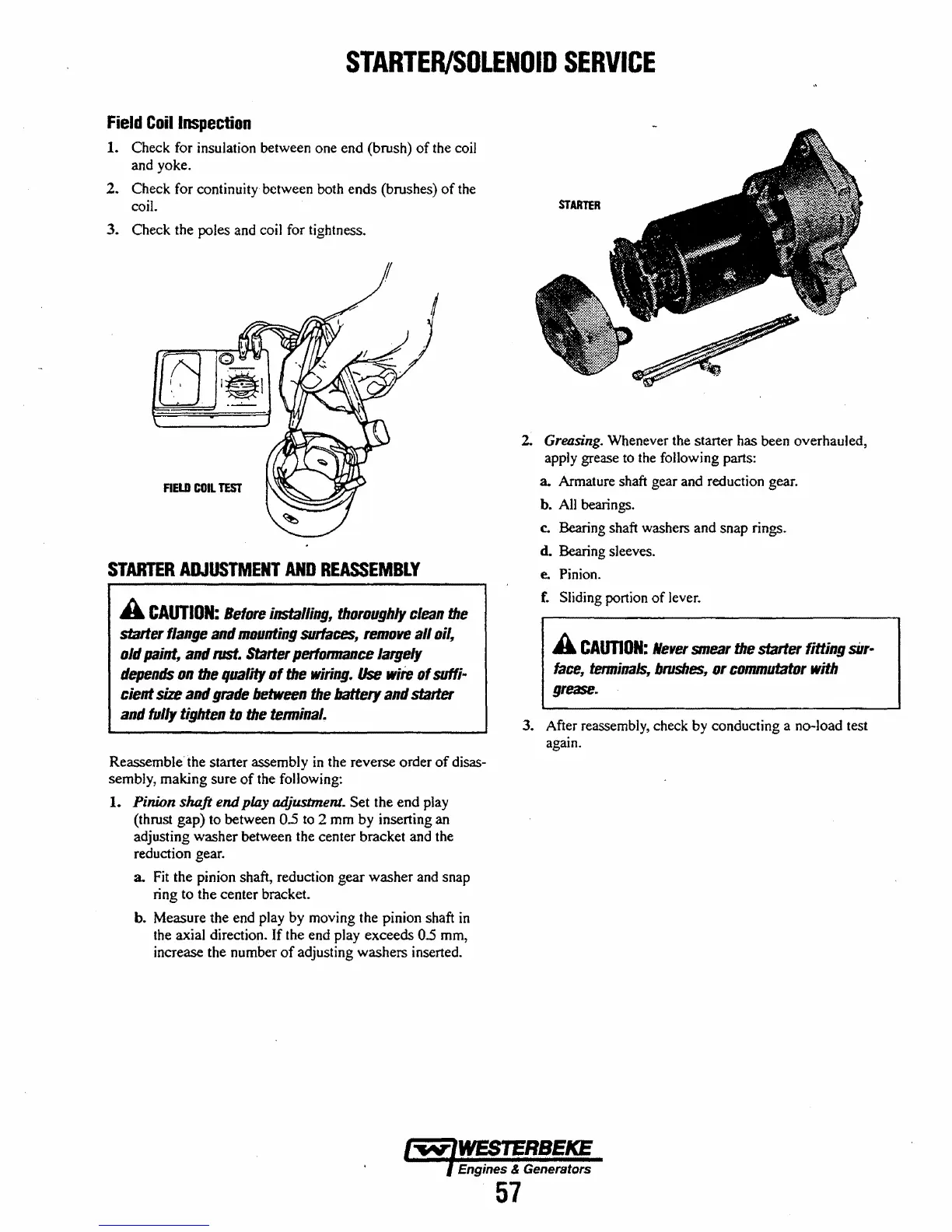

STARTER

ADJUSTMENT

AND

REASSEMBLY

A

CAUTION:

Before

installing,

thoroughly

clean

the

starter

flange

and

mounting

surfaces,

remove

all oil,

old

paint,

and

rust.

Starter

pertonnance

largely

depends

on

the

quality

of

the

wiring.

Use

wire

of suffi-

cient

size

and

grade

between

the

battery

and

starter

and

ful/y

tighten

to

the

terminal.

Reassemble" the starter assembly

in

the reverse order

of

disas-

sembly, making sure

of

the folJowing:

1. Pinibn shaft end

play

adjustment. Set the end play

(thrust gap) to between

0.5

to

2 mm by inserting an

adjusting washer between the center bracket and the

reduction gear.

a.

Fit

the pinion shaft, reduction gear washer and snap

ring to the center bracket.

b. Measure the end play by moving the pinion shaft

in

the axial direction. If the end play exceeds 0.5 mm,

increase the number

of

adjusting washers inserted.

2.

Greasing.

Whenever the starter has been overhauled,

apply grease to the following parts:

a.

Armature shaft gear and reduction gear.

h.

All

bearings.

c.

Bearing shaft washers and snap rings.

d. Bearing sleeves.

e.

Pinion.

f.

Sliding portion

of

lever.

A

CAUTION:

Ne"er

smear

the

starter fitting silr-

face,

terminals,

brushes,

Dr

commutator

with

grease.

3. After reassembly, check by conducting a no-load test

again.

Engines & Generators

57

Loading...

Loading...