CYLINDER

HEAD

SERVICE

DISASSEMBLY

1. Remove the air breather pipe. Remove the water bypass

hose if provided.

2. Remove the fuel injection lines.

3. Remove both the intake manifold and exhaust manifold

assemblies.

4. Remove the rocker cover.

S.

Remove the rocker arms and rocker shaft as an assembly.

6. Remove the push rods.

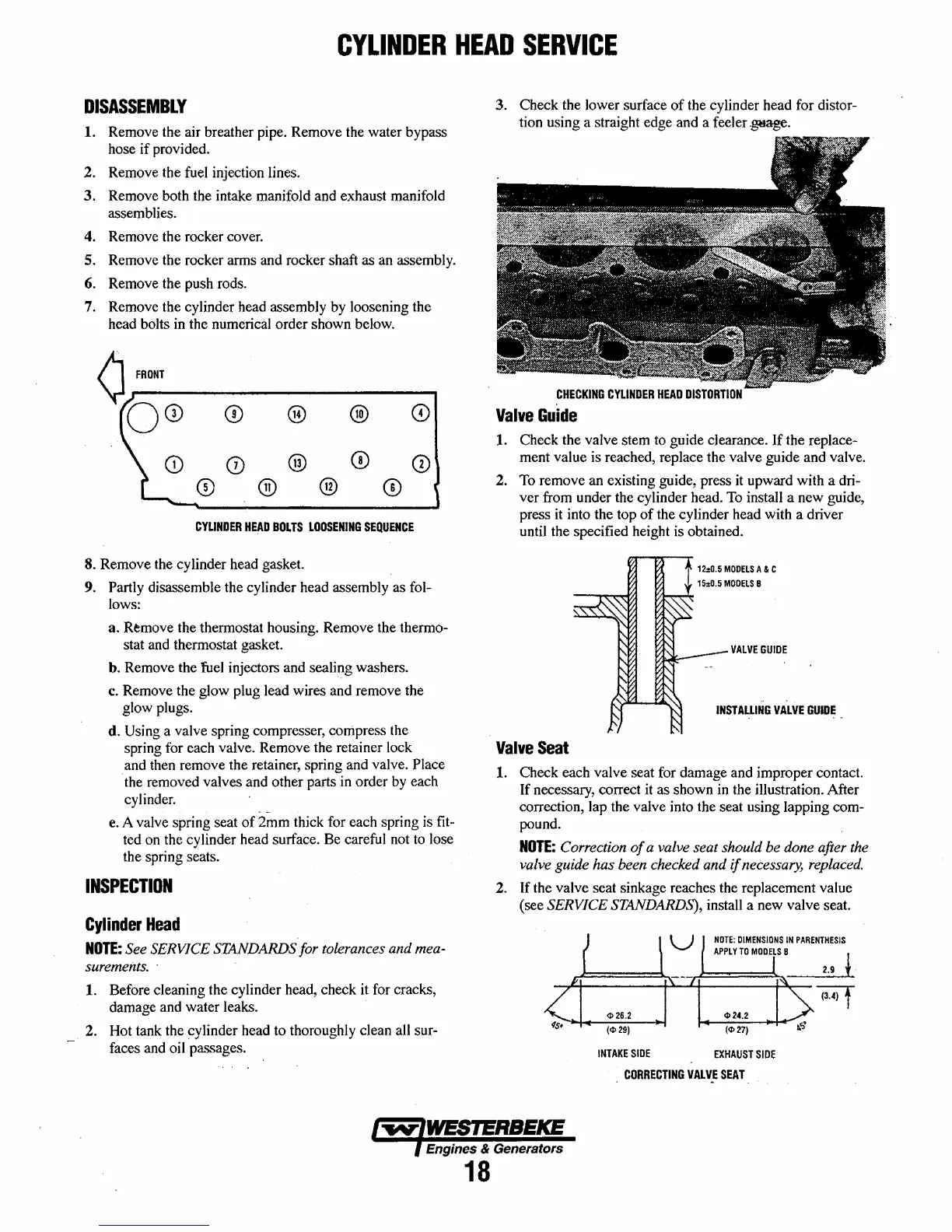

7. Remove the cylinder head assembly by loosening the

head bolts in the numerical order shown below.

®

®

®

®

®

CYLINDER

HEAD

BOLTS

LOOSENING

SEQUENCE

8. Remove the cylinder head gasket.

9.

Partly disassemble the cylinder head assembly as fol-

lows:

a.

Remove the thermostat housing. Remove the thermo-

stat and thermostat gasket.

b. Remove the fuel injectors and sealing washers.

c.

Remove the glow plug lead wires and remove the

glow plugs.

d. Using a valve spring com presser, compress the

spring for each valve. Remove the retainer lock

and then remove the retainer, spring and valve.

Place

the removed valves and other parts

in

order

by

each

cylinder.

e.

A valve spring seat

of

2mm thick for each spring is fit-

ted

on

the cylinder head surface. Be careful not to lose

the spring seats.

INSPECTION

Cylinder

Head

NOTE:

See SERVICE STANDARDS for tolerances and mea-

surements. .

1. Before cleaning the cylinder head, check it for cracks,

damage and water leaks.

2. Hot tank the cylinder head to thoroughly clean all sur-

faces and oil passages.

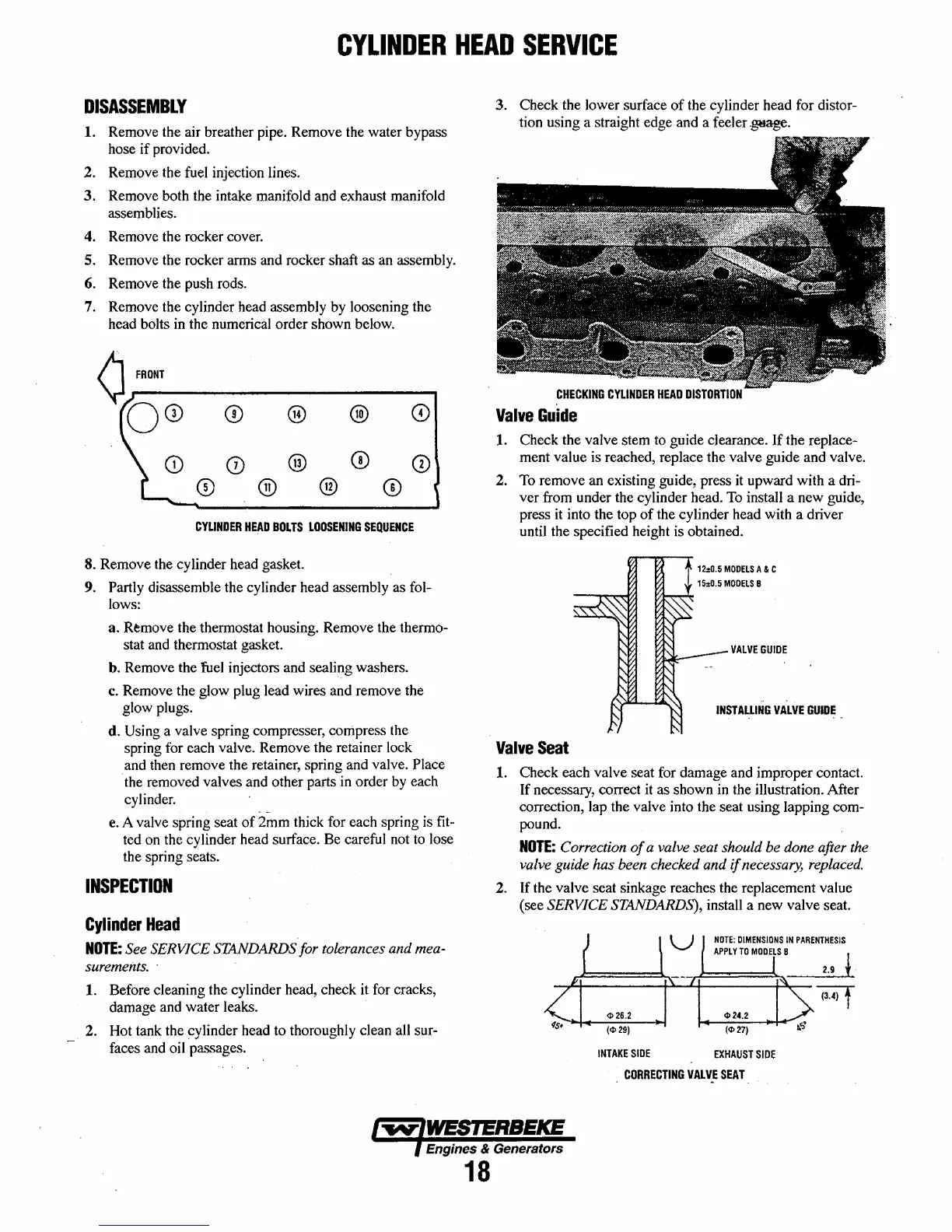

3. Check the lower surface

of

the cylinder head for distor-

tion using a straight edge and a feeler

~.

CHECKING

CYLINDER

HEAD

DISTORTION

Valve

Guide

1.

Check the valve stem to guide clearance.

If

the replace-

ment value is reached, replace the valve guide and valve.

2. To remove an existing guide, press

it

upward with a dri-

ver from under the cylinder head.

To

install a new guide,

press

it

into the top

of

the cylinder head with a driver

until the specified height is obtained.

12:0.5

MODELS

A & C

VALVE

GUIDE

INSTALLING

VALVE

GUIDE

Valve

Seat

1. Check each valve seat for damage and improper contact.

If necessary, correct

it

as shown

in

the illustration. After

correction, lap the valve into the seat using lapping com-

pound.

NOTE:

Correction

of

a valve seat should

be

done after the

valve guide has been checked and

if

necessary, replaced.

2. If the valve seat sinkage reaches the replacement value

(see

SERVICE STANDARDS), install a new valve seat.

2.9

t

INTAKE

SIDE

EXHAUST

SIDE

CORRECTING

VALVE

SEAT

. -

Engines

&

Generators

18

Loading...

Loading...